Method for continuous production of hydrolysate by methylchlorosilane concentrated acid hydrolyzing

A technology for hydrolysis of methyl chlorosilane and concentrated acid, applied in the direction of chlorine/hydrogen chloride, etc., can solve the problems of affecting the quality of hydrolyzates, reducing the speed of hydrolysis reaction, difficult to fully contact, etc. loss prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

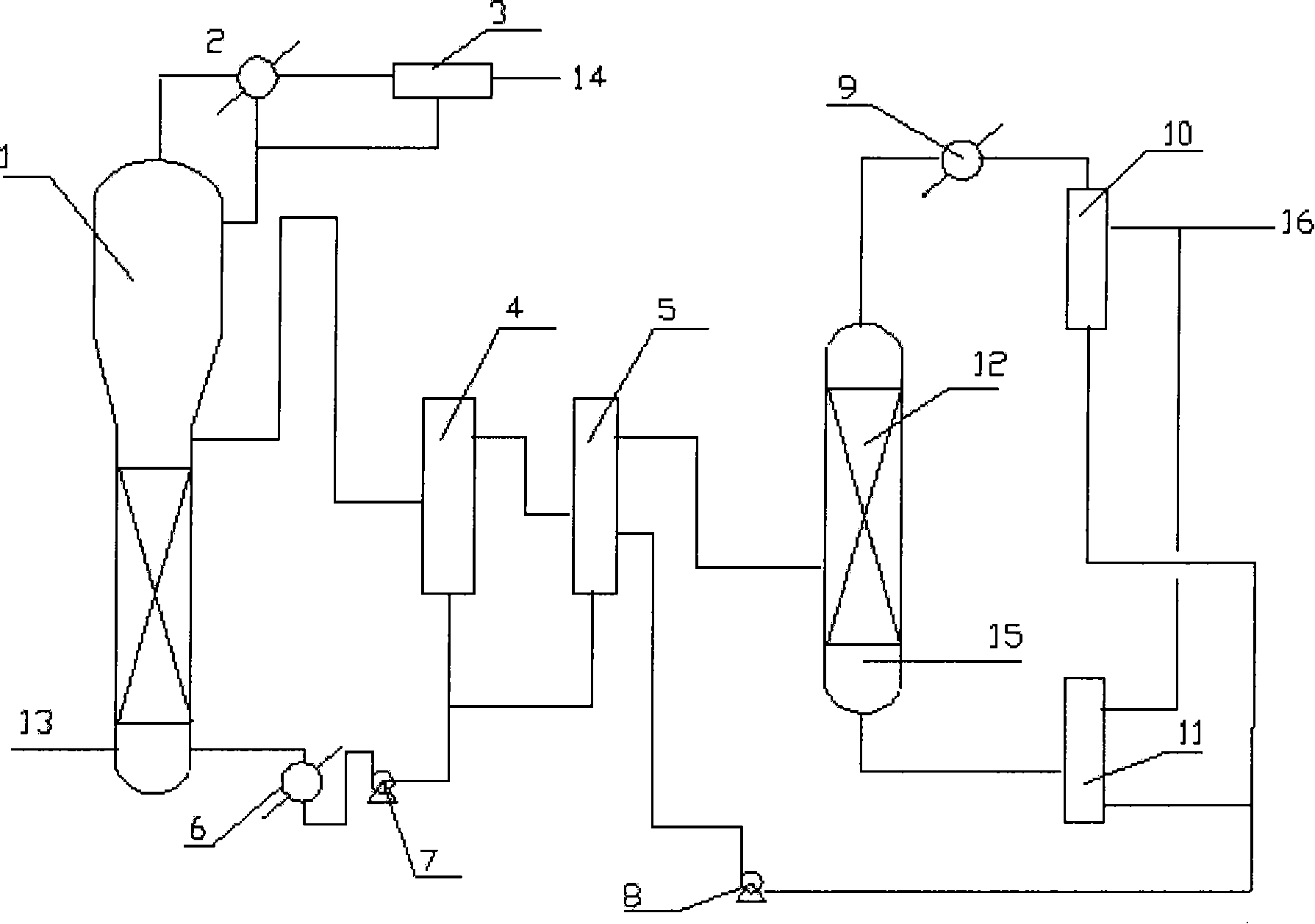

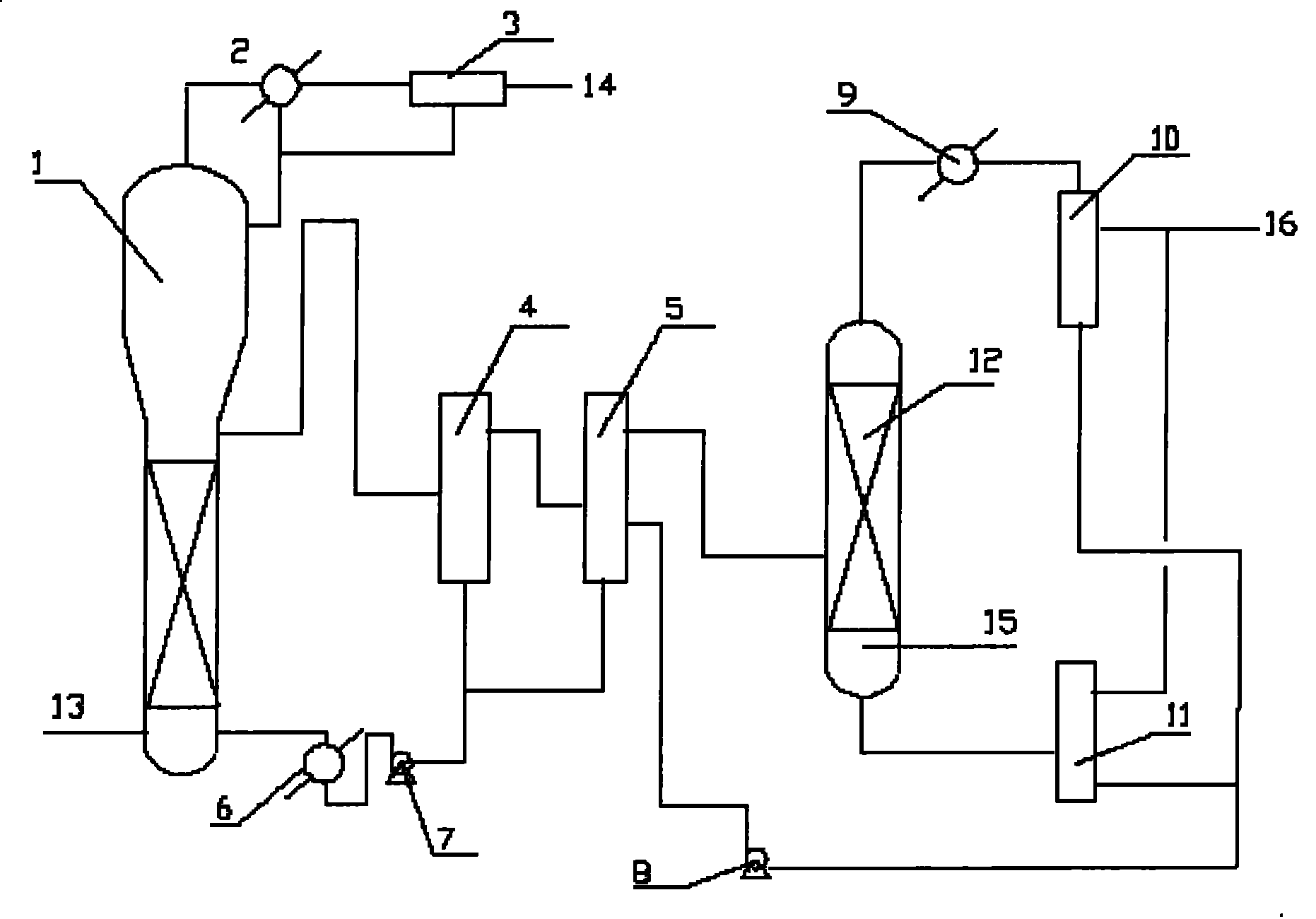

[0040] Embodiment 1: technical process such as figure 1 shown.

[0041] Dimethyldichlorosilane and concentrated acid enter the hydrolysis reactor 1 for hydrolysis reaction. The molar ratio of water to methylchlorosilane in the reaction system is 0.14:1, and part or all of the water can come from the primary phase separator 4 And the acidic aqueous solution of the secondary phase separator 5 (for recycling), control the reaction temperature at 35°C, the operating pressure at 0.3Mpa, and the residence time of 55 seconds. The hydrogen chloride generated by the reaction is released from the hydrolysis reactor and processed through the condenser 2 demister 3 Finally, it is discharged from the HCl outlet 14 and can be directly used for the production of methyl chloride. The liquid hydrolyzate is separated through the primary phase separator 4 and the secondary phase separator 5 successively. The oil phase in the upper layer is the acidic hydrolyzate, which enters the steam tower 1...

Embodiment 2

[0043] Embodiment 2: technical process such as figure 1 shown.

[0044] Dimethyldichlorosilane, concentrated acid and oil-containing acidic aqueous solution from the phase separator are metered into the hydrolysis reactor for hydrolysis reaction. The molar ratio of water to methylchlorosilane in the reaction system is 0.15:1, and the water in it can be Part or all of the acidic aqueous solution (for circulation) from the primary phase separator 4 and the secondary phase separator 5, the reaction temperature is controlled at 40°C, the operating pressure is 0.25Mpa, and the residence time is 45 seconds. The hydrogen chloride generated by the reaction is discharged from the hydrolysis reactor After being released by the condenser demister, it can be directly used in the production of methyl chloride. The liquid hydrolyzate enters the primary and secondary phase separators, and the separated upper oil phase is acidic hydrolyzate, which enters the steam tower through the interfac...

Embodiment 3

[0047] Dimethyldichlorosilane, concentrated acid and the oil-containing acidic aqueous solution from the phase separator are metered into the packed tower hydrolysis reactor 1 for hydrolysis reaction. The molar ratio of water and methylchlorosilane in the reaction system is 0.14:1, The water wherein can partly or entirely come from the acidic aqueous solution (recycling) of primary phase separator 4 and secondary phase separator 5, control reaction temperature 40 ℃, operating pressure 0.3Mpa, residence time 55 seconds, the hydrogen chloride that reaction generates After being released from the upper part of the hydrolysis reactor and passed through the condenser demister, it can be directly used for the production of methyl chloride. The liquid hydrolyzate passes through the primary and secondary phase separators, and the oil phase obtained in the upper layer is acidic hydrolyzate, which enters the steam tower through the interface control; the acidic water obtained in the lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com