Piezoelectric thin film, piezoelectric material, and fabrication method of piezoelectric thin film and piezoelectric material, and piezoelectric resonator

A manufacturing method and piezoelectric body technology, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, piezoelectric devices/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, etc., can solve Narrowing of the movable area, low piezoelectric constant, increased loss, etc., to achieve the effect of improving detection sensitivity, reducing insertion loss, and expanding the movable area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

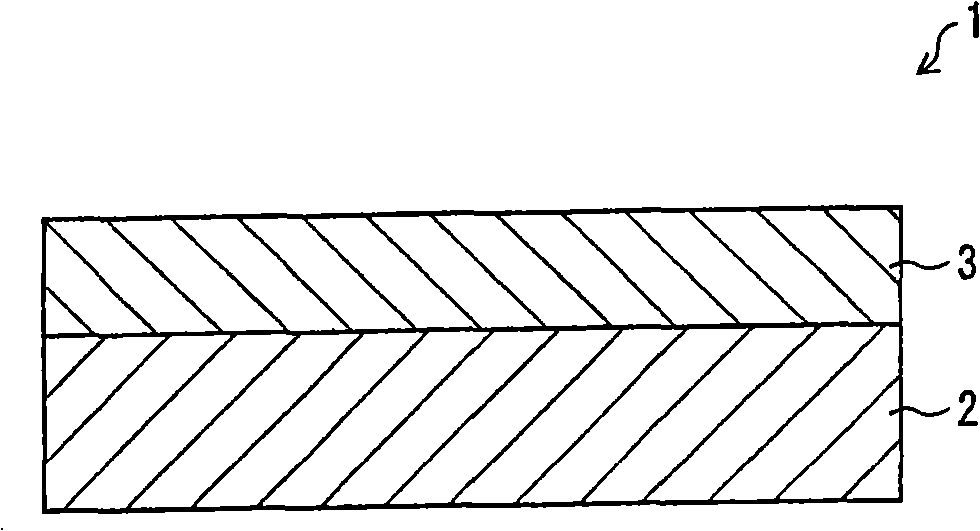

[0069] Refer below figure 1 and 2 , an embodiment of the piezoelectric thin film of the present invention will be described as Embodiment 1. FIG.

[0070] In addition, when the piezoelectric thin film of the present invention is used for a piezoelectric element utilizing a piezoelectric phenomenon, its specific use is not particularly limited. For example, piezoelectric thin films can be used in SAW devices or RF-MEMS devices. Here, a "piezoelectric body" in this specification and the like refers to a substance having piezoelectricity (hereinafter also referred to as piezoelectric responsiveness), which is a property of generating a potential difference when a mechanical force is applied. In addition, the term "piezoelectric thin film" refers to a thin film having the above properties.

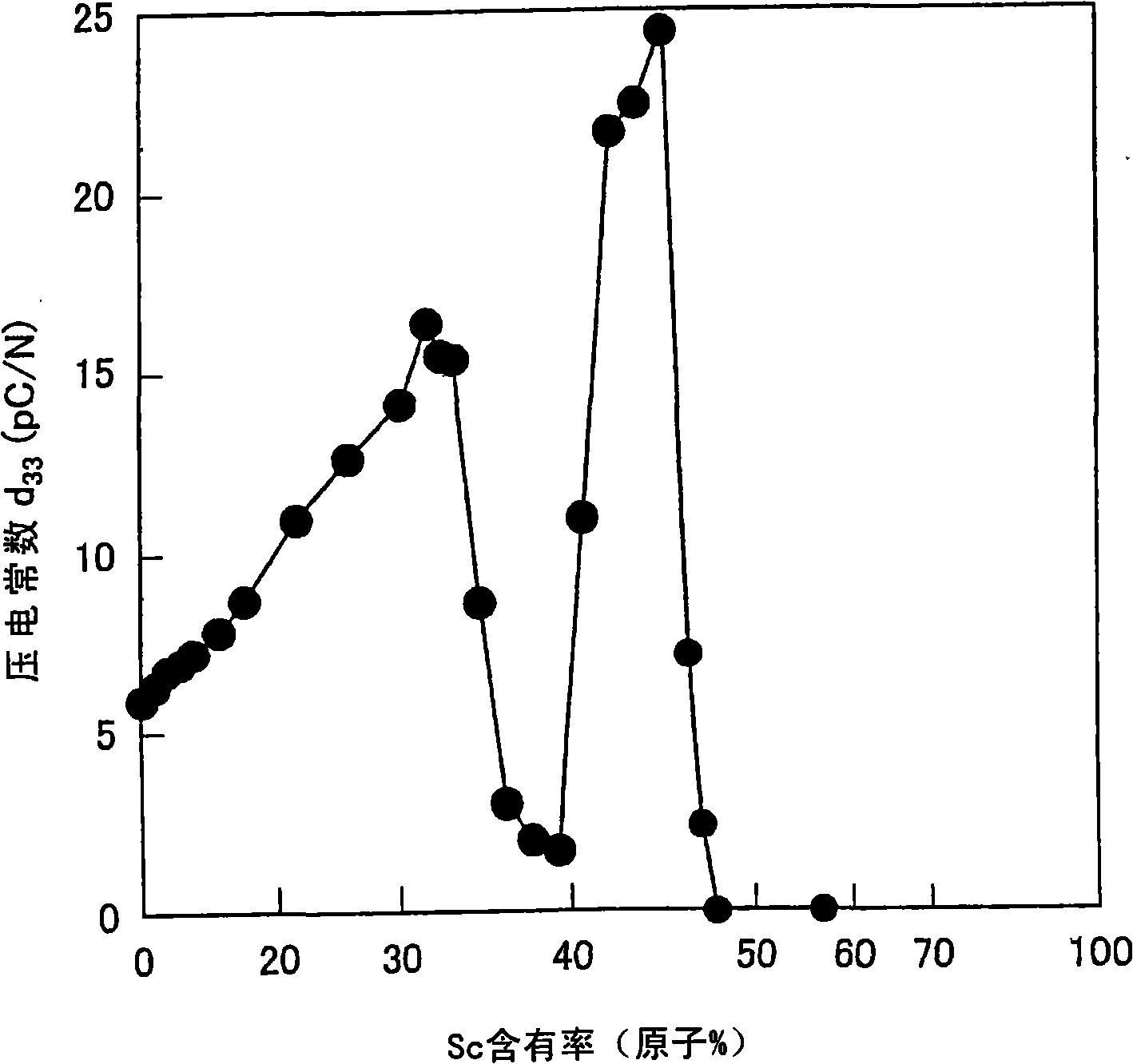

[0071] In addition, the so-called "atomic %" in this specification etc. means an atomic percentage, specifically, it means the number of scandium atoms or the number of aluminum atoms when th...

Embodiment approach 2

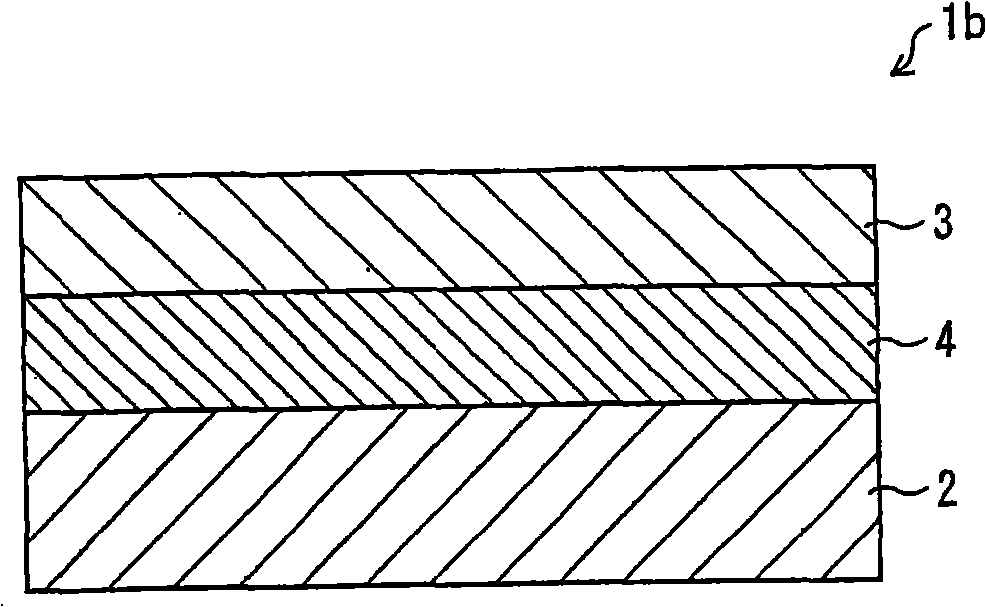

[0088] Refer to the attached Figure 3-5 Another embodiment of the piezoelectric thin film of the present invention will be described as Embodiment 2. In this embodiment, the same components as in Embodiment 1 are given the same reference numerals. In addition, the same term as Embodiment 1 also uses the same meaning in this embodiment.

[0089] (Structure of Piezoelectric Thin Film 1b)

[0090] like image 3 As shown, in the piezoelectric thin film 1 b of the present embodiment, the intermediate layer 4 is formed between the substrate 2 and the Sc-containing aluminum nitride thin film 3 . That is, in the piezoelectric thin film 1b, the Sc-containing aluminum nitride thin film 3 is provided on the substrate 2 via the intermediate layer 4 . In the first embodiment, the substrate 2 and the Sc-containing aluminum nitride thin film 3 have been described, and thus detailed description thereof will be omitted here. Therefore, in this embodiment, only the intermediate layer 4 wi...

Embodiment approach 3

[0108] Refer below Image 6 One embodiment of the method for manufacturing the piezoelectric thin film 1 according to the first embodiment will be described as a third embodiment. In addition, the specific use of the Sc-containing aluminum nitride thin film is not particularly limited as long as it is used in a piezoelectric element utilizing the piezoelectric phenomenon. For example, a piezoelectric thin film having an Sc-containing aluminum nitride thin film can be used in a SAW device or an RF-MEMS device. In addition, in this embodiment, the same term as Embodiment 1 uses the same meaning.

[0109] The manufacturing method of the piezoelectric thin film 1 includes a sputtering process, that is, in nitrogen (N 2 ) atmosphere or nitrogen (N 2 ) and argon (Ar) in a mixed atmosphere, on the substrate 2 (for example, a silicon (Si) substrate) simultaneously sputtering scandium and aluminum. Thereby, the Sc-containing aluminum nitride thin film 3 having excellent adhesion an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com