Non-solder laser welding method and device of network transformator

A network transformer and laser welding technology, applied in laser welding equipment, inductance/transformer/magnet manufacturing, auxiliary devices, etc. Soldering needs solder and other issues to achieve the effect of saving welding materials, firm and beautiful solder joints, and fast welding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

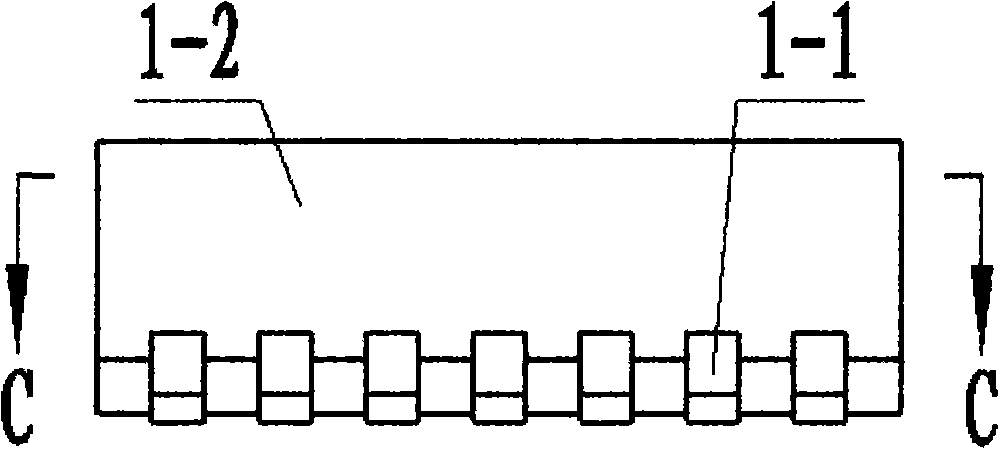

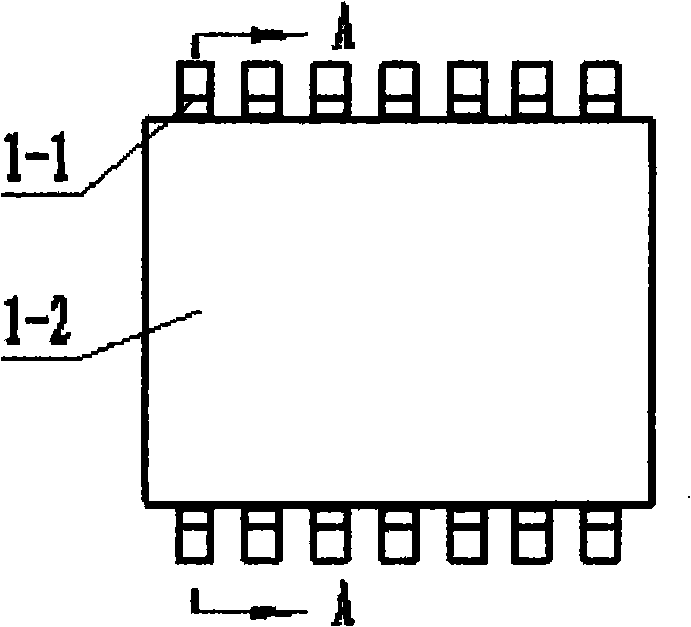

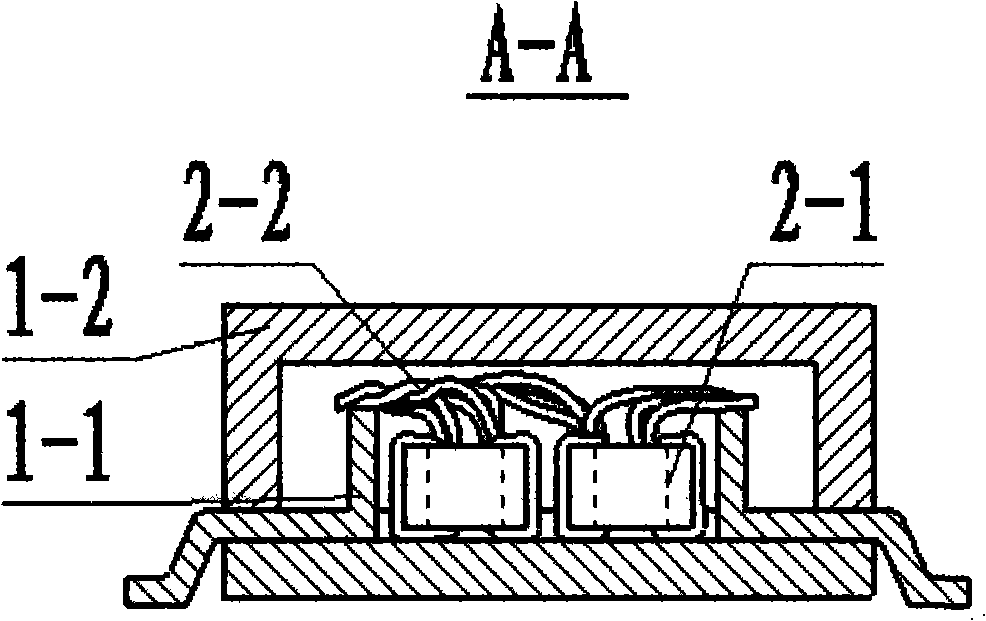

[0045] Such as Figure 6 As shown, laser welding is performed on a single network transformer. The device of the solderless laser welding method of the network transformer includes a positioning device connected to a microcomputer 6 and its signal, a laser welding device, and a shielding gas device. The positioning device includes a clamp 3. The workbench 5, the clamp 3 is embedded and fixed with the magnetic ring coil wire 2-2 of the network transformer at the lowest position of the lift, and the pin frame 1 of the network transformer is fixedly connected with the workbench 5; The above-mentioned laser welding device adopts a dynamic focusing first and then scanning method, which includes a laser 7, a beam expander 8, a dynamic focusing unit 9 and a dynamic focusing unit composed of a focusing mirror 10, an X-axis scanning galvanometer 11, a Y-axis Scanning vibrating mirror 12; described shielding gas device comprises nozzle 4 and switch mechanism thereof, described two nozzl...

Embodiment 2

[0056] Such as Figure 6 , 7 As shown, for a plurality of network transformers to perform pipeline laser welding, the laser welding device of the non-soldering material network transformer includes a positioning device connected to a microcomputer 6 and its signal, a laser welding device, and a shielding gas device. The positioning device includes Fixture 3, conveyor belt 5, the fixture 3 is embedded and fixed with the magnetic ring coil wire 2-2 of the network transformer at the lowest position of lifting, and the pin frames 1 of multiple network transformers are fixedly connected with the conveyor belt 5 in turn ; The laser welding device adopts a scanning mode after first dynamic focusing, which includes a dynamic focusing unit composed of a laser 7, a beam expander 8, a dynamic focusing unit 9 and a focusing mirror 10 connected by an optical path, an X-axis scanning galvanometer 11, The Y-axis scanning vibrating mirror 12; the shielding gas device includes a nozzle 4 and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com