Synthetic method of non-linear structure polycaprolactone-block-polyethyleneglycol

A polyethylene glycol, polycaprolactone technology, applied in the chemical industry, can solve the limitation, difficult copolymer degradation and drug controlled release performance, no polycaprolactone-block-polyethylene glycol preparation method is provided, etc. problem, to achieve the effect of convenient operation and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

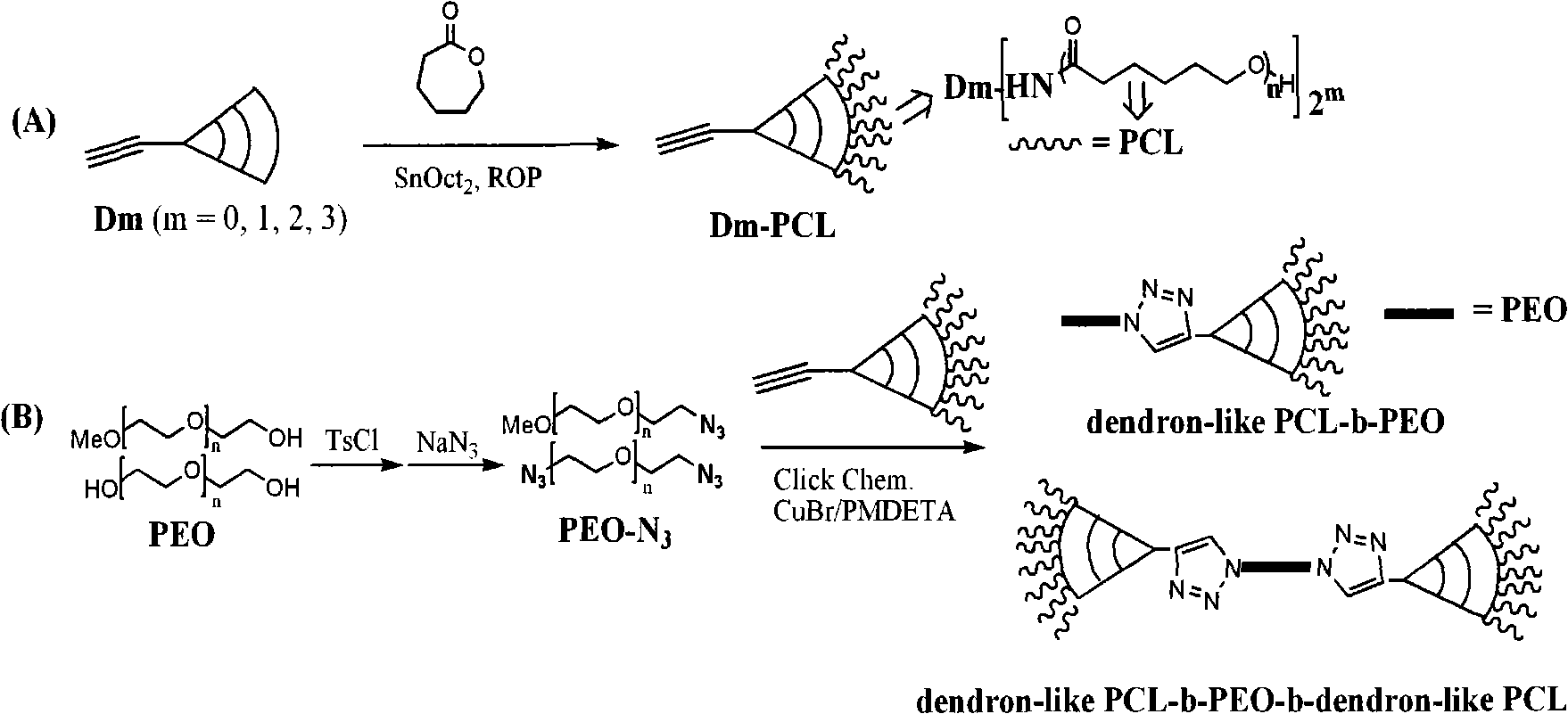

[0015] Synthetic method of polycaprolactone-block-polyethylene glycol with sector-linear structure

[0016] Polyethylene glycol with azide-terminated linear structure (PEO-N 3 ) with a linear structure of alkynylated polycaprolactone (Dm-PCL) in a one-step "click chemistry" reaction: Weighing polyethylene glycol PEO-N with azidated linear structure 3 (110.0mg, 0.219mmol) and linear structure alkynylated polycaprolactone Dm-PCL (118.1mg, 0.199mmol alkynyl) were added to a 25mL eggplant-shaped reaction flask, completely dissolved in 2mL DMF, and bromine was added under nitrogen Cuprous chloride (CuBr, 3.1 mg, 0.0219 mmol) was reacted with pentamethyldivinyltriamine (PMDETA, 5 μL, 0.0219 mmol) at 35° C. for 24 hours. After the reaction, the polymer solution was settled in a large amount of ether, and purified by solvent extraction with 10 mL of cold methanol (about 10 °C) to completely remove excess PEO-N 3 . The product was vacuum-dried at 40° C. to obtain 158.5 mg of fan-lin...

Embodiment 2

[0018] Synthetic method of polycaprolactone-block-polyethylene glycol with fan-linear-fan structure

[0019] Double-terminal azidated linear polyethylene glycol (N 3 -PEO-N 3 ) with a linear structure of alkynylated polycaprolactone (Dm-PCL) one-step "click chemistry" reaction: Weigh the two-terminal azidated linear structure of polyethylene glycol N 3 -PEO-N 3 (50.0mg, 0.0123mmol) and linear structure alkynylated polycaprolactone Dm-PCL (131.6mg, 0.0272mmol alkynyl) were added to a 25mL eggplant-shaped reaction flask, completely dissolved in 1.5mL DMF, and added under nitrogen Cuprous bromide (CuBr, 3.9 mg, 0.0272 mmol) was reacted with pentamethyldivinyltriamine (PMDETA, 6 μL, 0.0272 mmol) at 35° C. for 36 hours. After the reaction, the polymer solution was settled in a large amount of ether. Using a solvent extraction method, a mixed solution of benzene and n-hexane (10 mL, benzene:n-hexane=0.7:1, volume ratio) was used to completely remove excess Dm-PCL. The product w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com