Automatic control system and control method of optical filming

An automatic control and optical coating technology, applied in optics, optical components, comprehensive factory control, etc., can solve the problems of unstable product quality, complicated coating debugging of coating machines, waste of optical materials and film materials, etc., to meet the needs of large batches Production requirements, rich software and hardware resources, accurate and stable coating quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

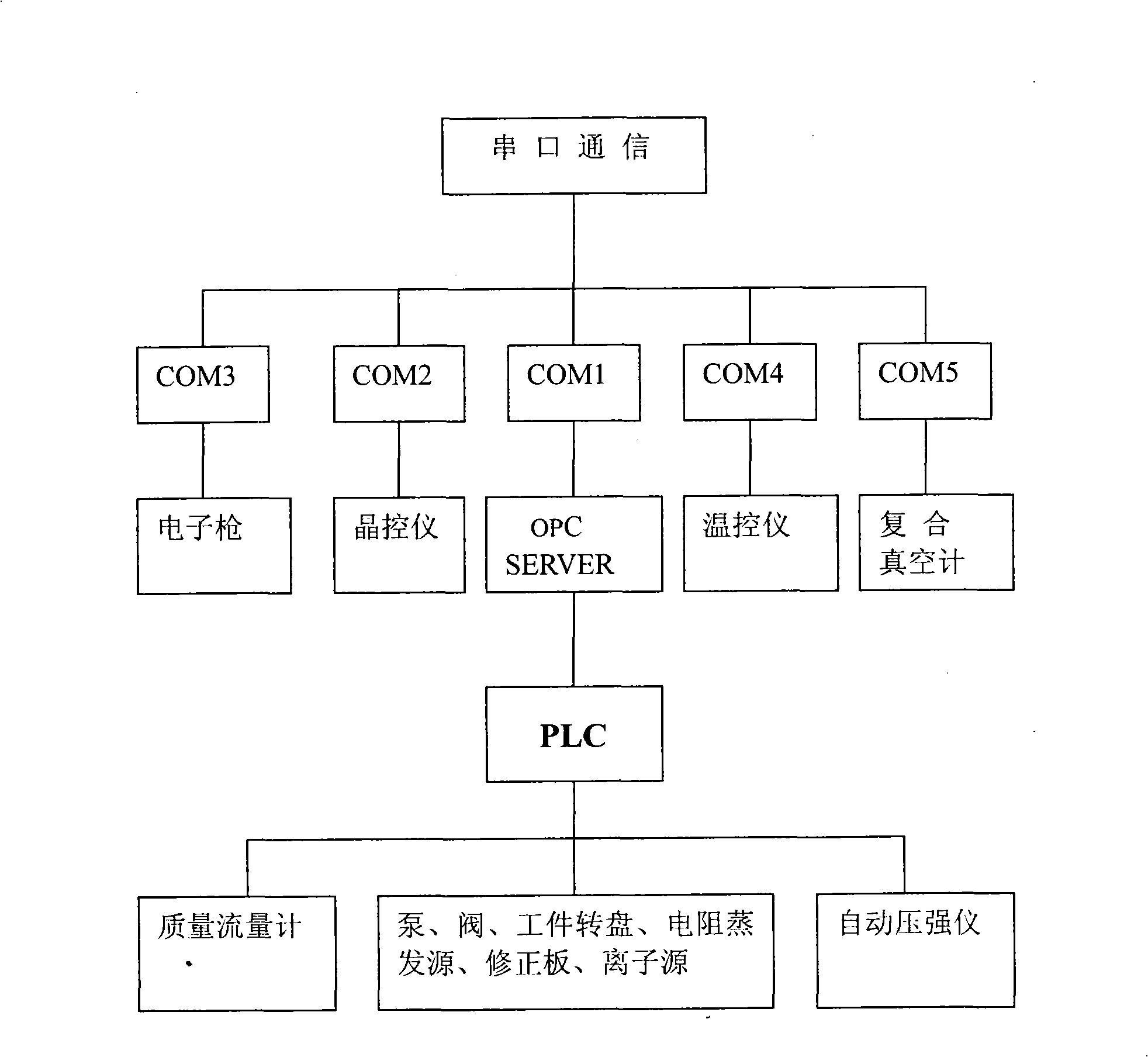

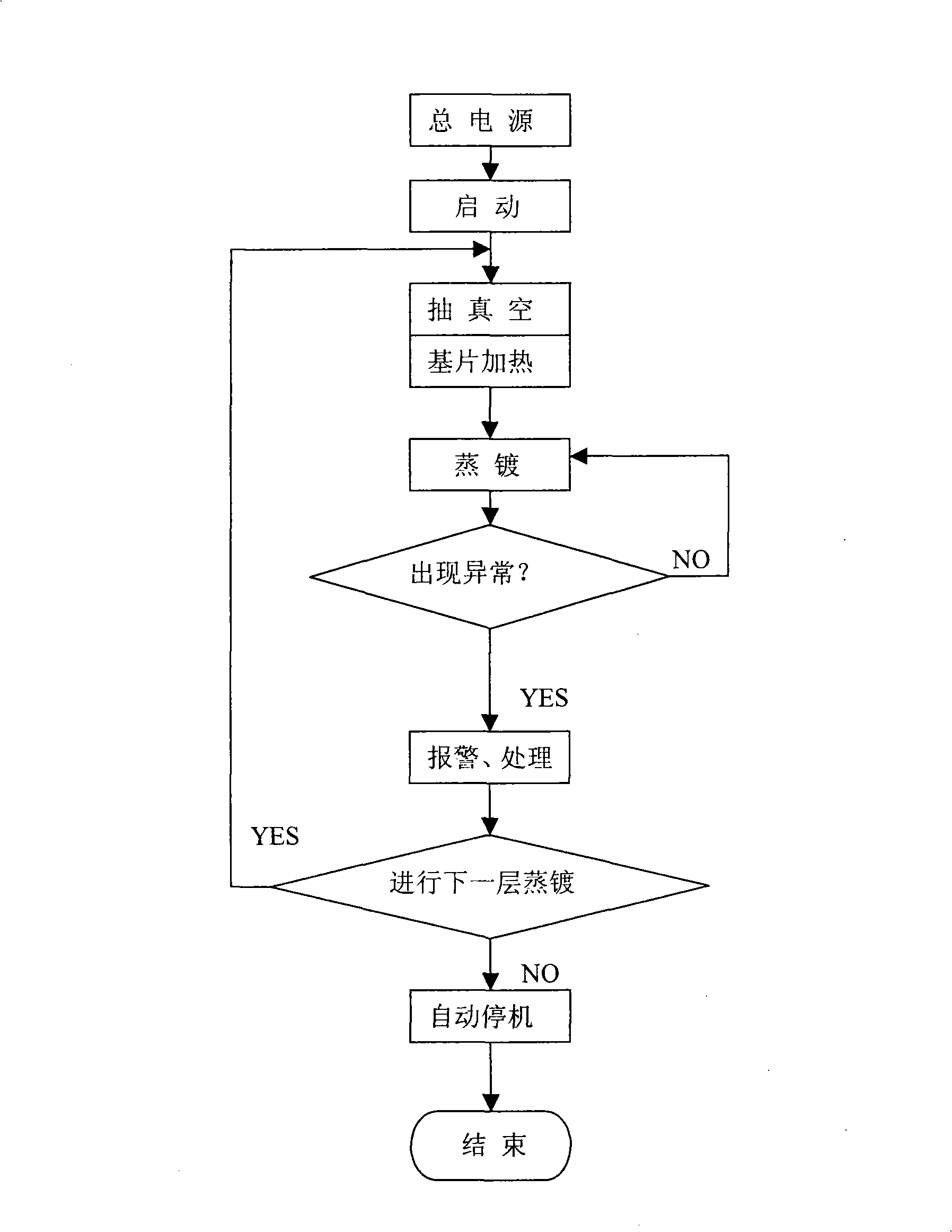

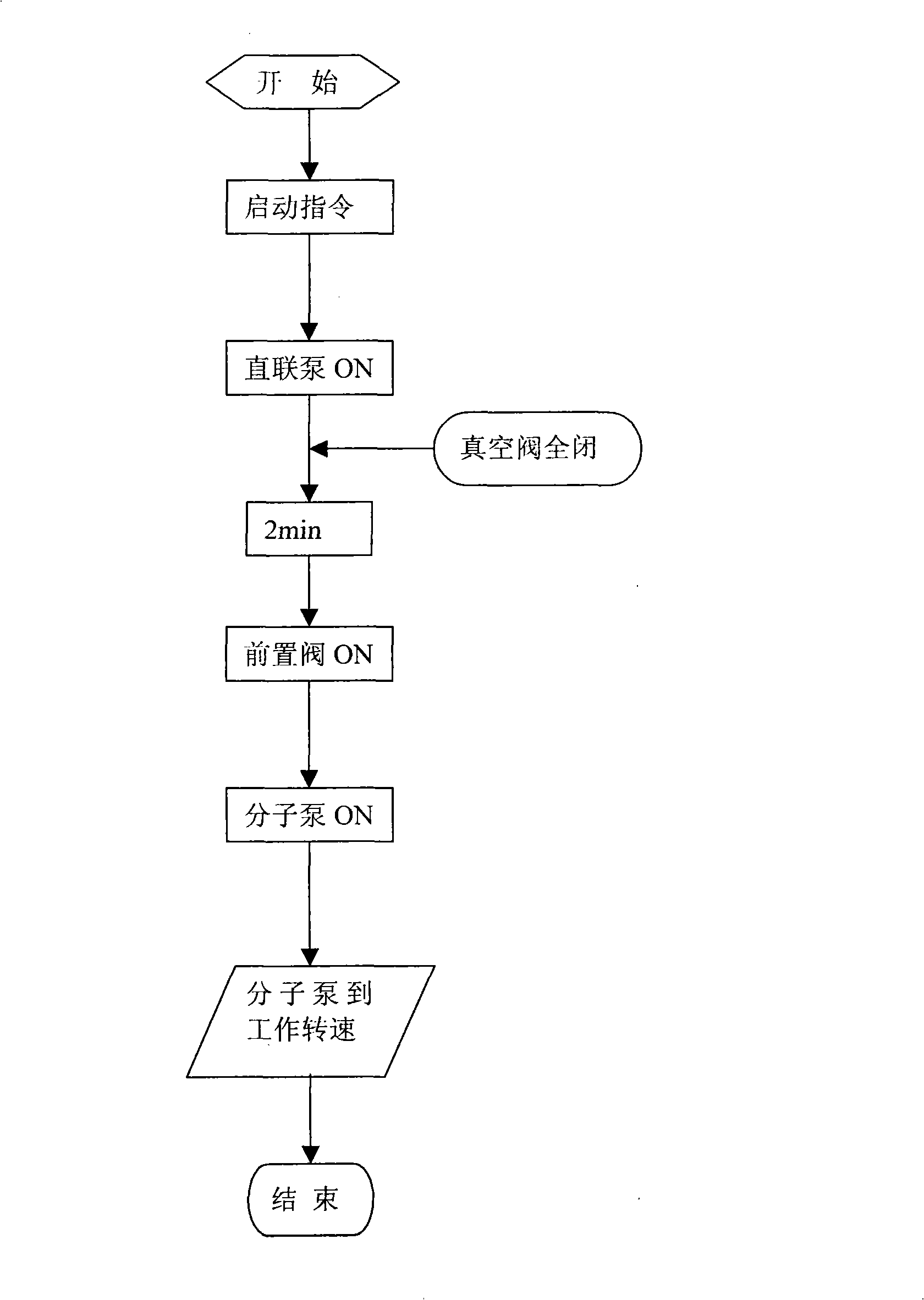

[0039] see figure 1 , the optical coating automatic control system of the present invention adopts the OPC technology, adopts serial port communication, and uses the control software developed by C language to control the coating machine from vacuuming to coating process including vacuuming, evaporation, gas filling, workpiece disk rotation, and crucible replacement. Automatic operation and full-automatic control of actions such as position and comparison sheet, to realize full-automatic single-layer or multi-layer film thickness control. The automatic control system includes a hardware system and a software system. The hardware system has an industrial computer, a display with a touch screen connected to it, a crystal controller connected through serial communication, and a set of temperature controllers composed of 4 PID digital temperature controllers. instrument, composite vacuum gauge, electron gun and control unit. in:

[0040] The function of the industrial computer i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com