Releasable resin composition, molded object thereof, and layered product

A resin composition, mold release technology, applied in the direction of synthetic resin layered products, film/sheet release liners, layered products, etc., can solve the problems of smoke, low thermal stability, foaming, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

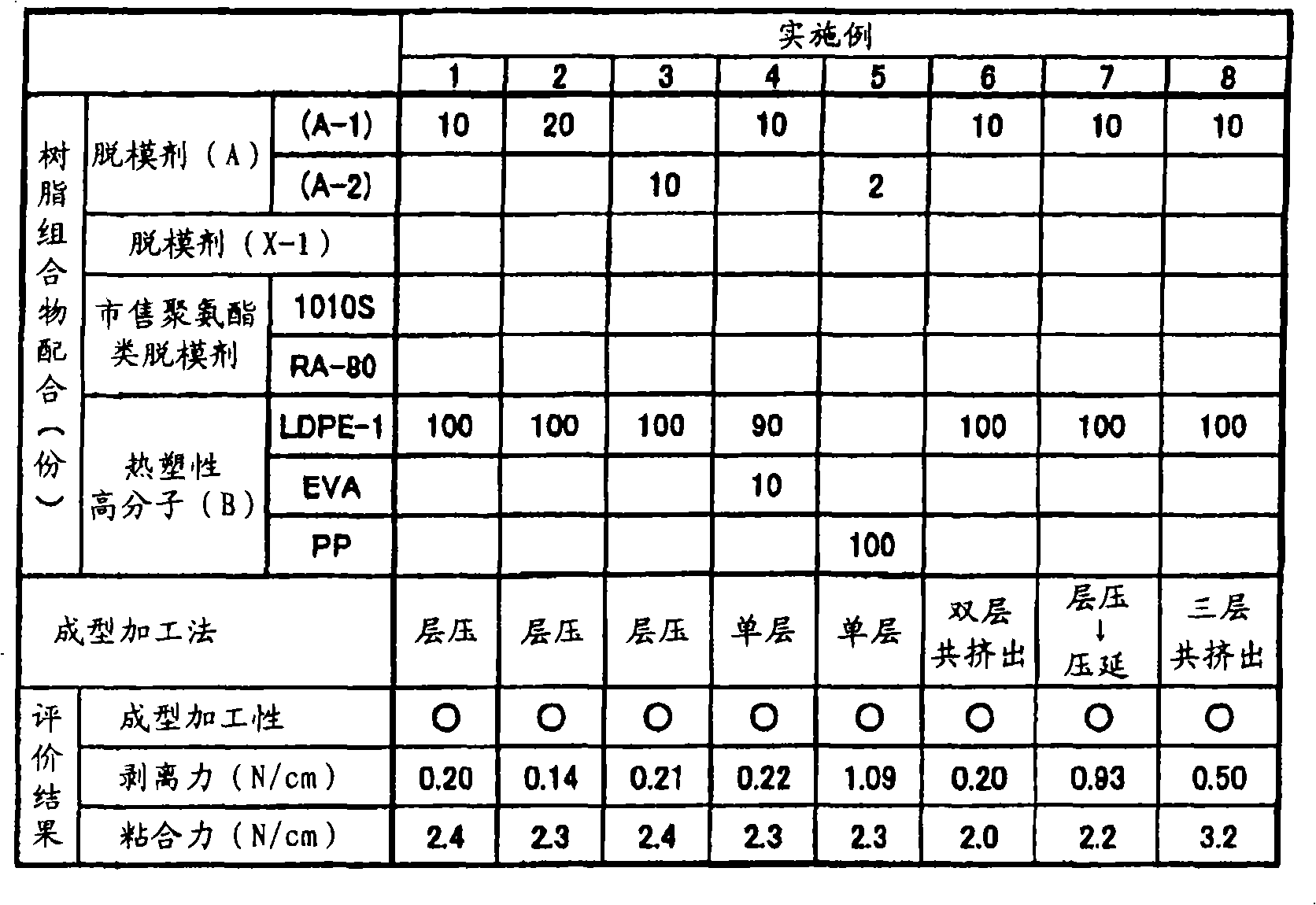

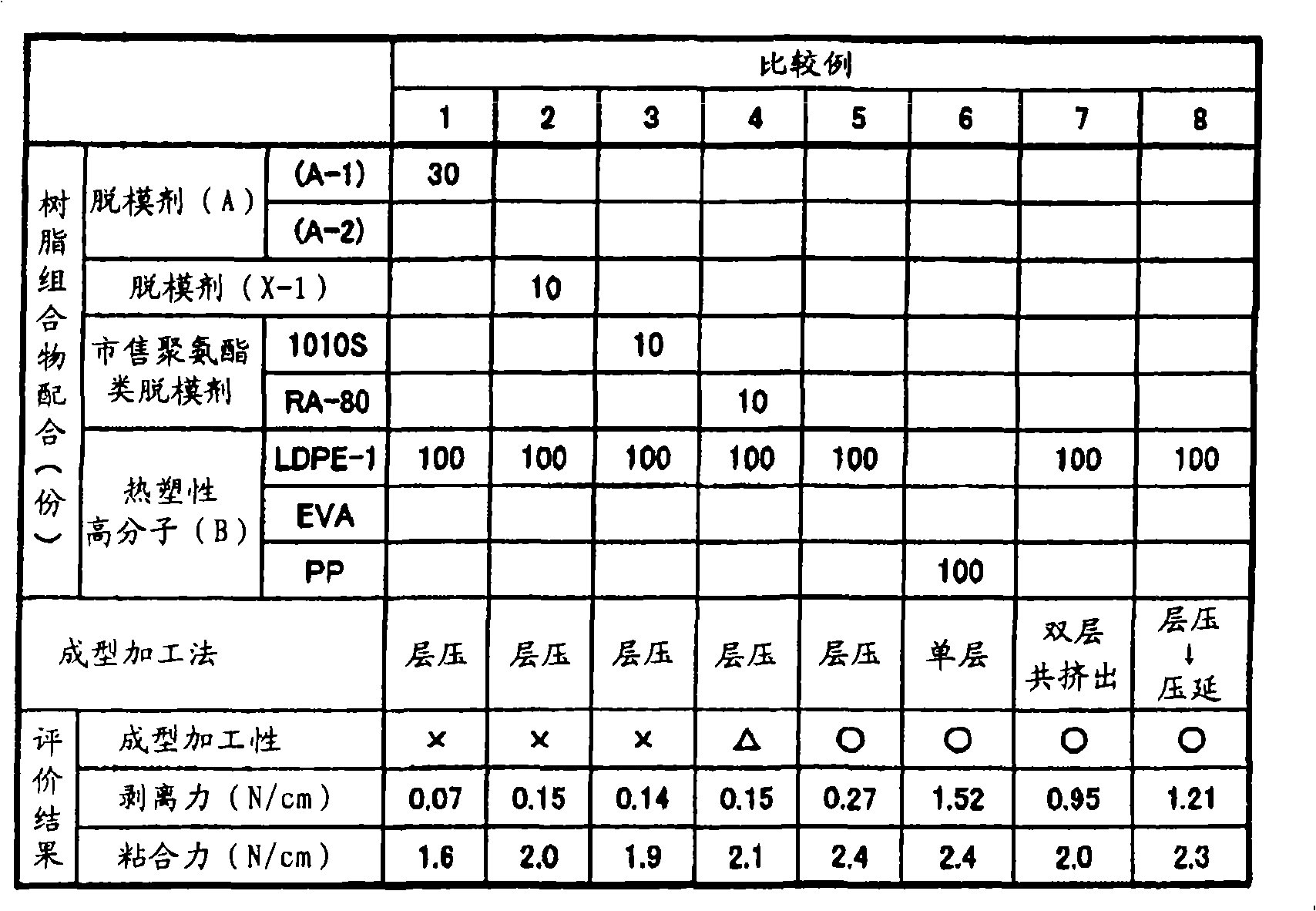

[0057] Hereinafter, although an Example demonstrates this invention more concretely, this invention is not limited to the following Example unless the gist is exceeded.

[0058] Also, hereinafter, "parts" all mean "parts by weight".

[0059] [Analytical method]

[0060] The analysis methods of the mold release agents and thermoplastic polymers used in the following examples are as follows.

[0061](1) Weight-average molecular weight of polymer compound: evaluated by GPC method. The device uses "HLC8020" manufactured by Tosoh Corporation (solvent: tetrahydrofuran, temperature: 40°C, flow rate: 1.0ml / min, column: PLgel 10μm MIXED-B 30cm x 2, detector: RI (built-in the device) )) means that in the obtained molecular weight distribution diagram, the molecular weight ratio polystyrene conversion molecular weight is 3.0×10 3 The weight average molecular weight of the component with a high peak valley (minimum value) in the vicinity.

[0062] (2) 2% and 5% weight reduction temper...

preparation example 1

[0071] Ethylene-acetic alcohol copolymer (manufactured by Kuraray Co., Ltd., trade name "Eval E-171B", ethylene structural unit: 44 mol%, weight average molecular weight: 9.17 × 10 4 ) 100 parts were dispersed in 1160 parts of toluene, while refluxing for 2 hours, the moisture was separated and removed on the way of the reflux device. Then, it was cooled to 40° C., 280 parts of dimethyl sulfoxide was added, and 269 parts of octadecyl isocyanate (manufactured by Hodogaya Chemical Industry Co., Ltd., trade name “Mirionet ○”) was added dropwise while stirring, so that The equivalent ratio of the isocyanate group to the hydroxyl group of the ethylene-vinyl alcohol copolymer was 0.6 equivalent, and the reaction was carried out at 120° C. for 4 hours. During the period, the residual isocyanate groups in the system were quantified with an infrared spectrophotometer (2260cm -1 near), with the disappearance point of the residual components as the end point.

[0072] After completion ...

preparation example 2

[0075] Except for the use of ethylene-vinyl alcohol copolymer (manufactured by Kuraray Co., trade name "Eval E-151B", ethylene structural unit: 44 mol%, weight average molecular weight: 1.23×10 5 ) to replace the ethylene-vinyl alcohol copolymer used in Preparation Example 1, the same operation as Preparation Example 1 to obtain a weight average molecular weight of 1.59 × 10 5 , the total content of impurity [2] and impurity [3] is 0.11% by weight, the addition amount of isocyanate is 34 mol%, and the release agent (A) (A) ( Hereinafter referred to as "release agent (A-2)").

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com