Polymer PTC heat sensitive material obtained by compound extruding method

A heat-sensitive material and polymer technology, applied in the field of polymer PTC heat-sensitive materials, can solve the problems such as the metal electrode and the polymer matrix are not tightly combined, it is difficult to meet the requirements of the thermistor, and it is difficult to ensure the uniformity of the metal coating. To achieve the effect of avoiding the possibility of environmental pollutants, low cost and large production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

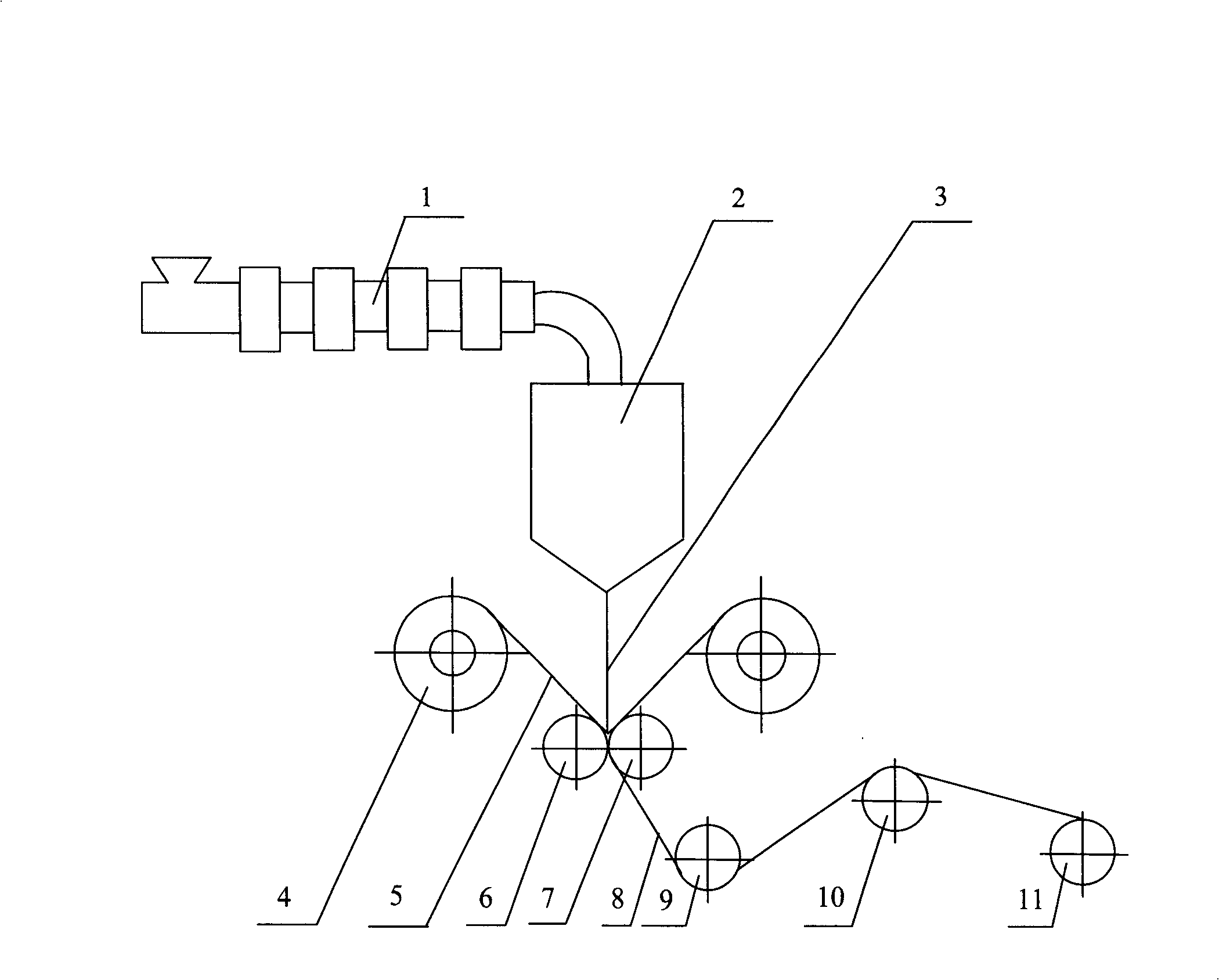

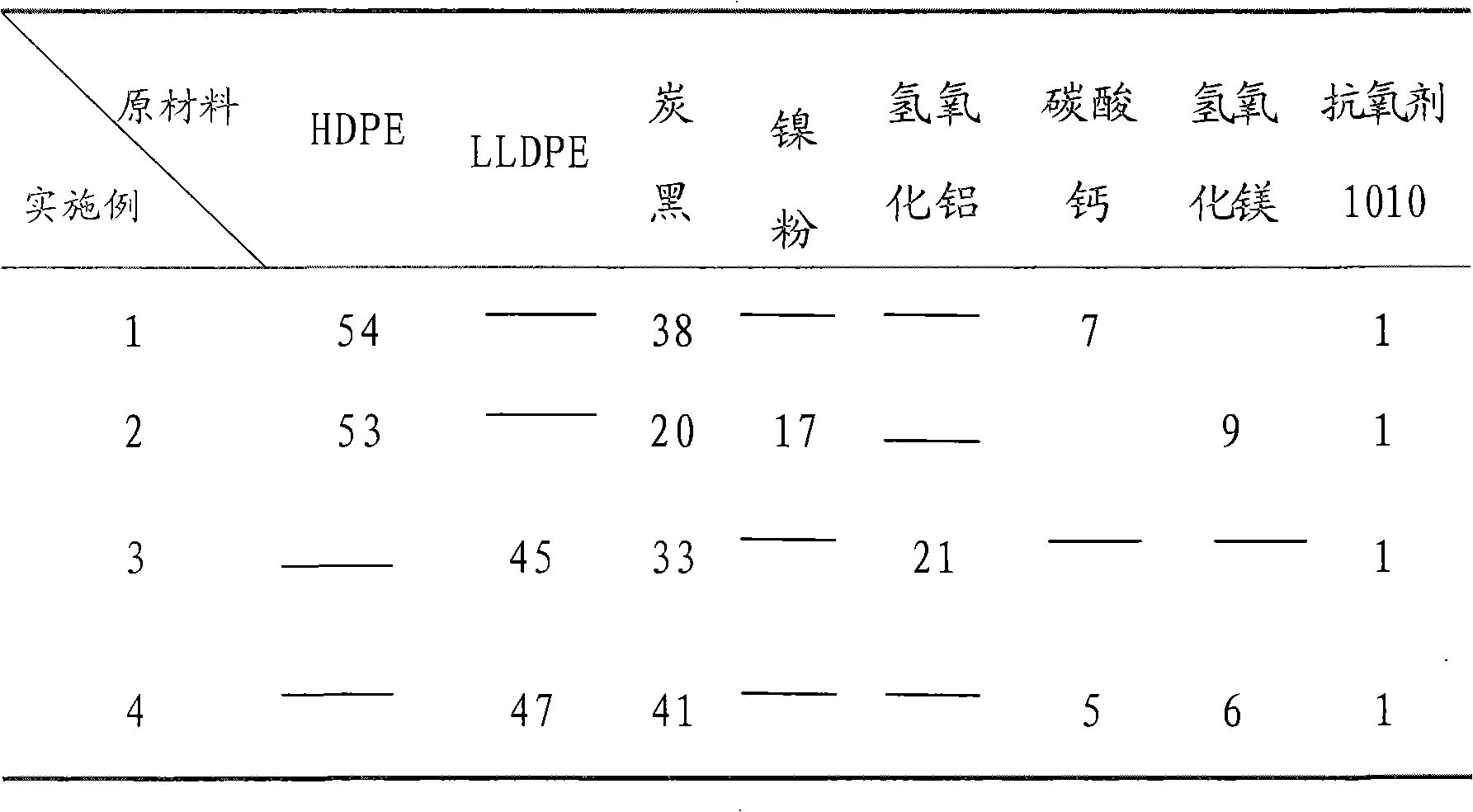

[0040] Add the masterbatch prepared by the formula in Table 1 and the conventional method into the compound group of the extruder, and the equipment used is such as figure 1 shown. The masterbatch is extruded by a twin-screw extruder in a molten state (melting processing temperature is 200-240°C), and reaches the extrusion die through a connecting pipe (the temperature at the die is 190-230°C). The molten resin is compounded with two layers of aluminum foil on the left and right by twin-roll extrusion, and a film with a thickness of 50 μm and a width of 1.5 m is obtained through a quenching roll at 30-40 ° C. The heat-sensitive film is then subjected to gamma rays (Co 60 ) irradiation with a dose of 50-80Mrad, the polymer PTC thermosensitive film of the present invention is obtained.

Embodiment 2

[0042] The raw materials in Table 1 are mixed by an internal mixer and then directly extruded through a single-screw or twin-screw extruder to form a molten state (melting processing temperature is 200-240 ° C), and reach the extrusion die through the connecting pipe (die head temperature at 190-230°C), the molten resin is compounded with two layers of copper foil on the left and right by twin-roll extrusion at the die head, and after a quenching roll at 80-100°C, a film with a thickness of 50 μm and a width of 1.5 m is obtained. film. Then, the heat-sensitive film is irradiated with electron beams, and the dose is 50-80 Mrad, so as to obtain the polymer PTC heat-sensitive film of the present invention.

Embodiment 3

[0044] Add the masterbatch prepared in Table 1 into the compounding group of the extruder. The masterbatch is extruded through a single-screw or twin-screw extruder in a molten state (melting processing temperature is 200-240°C), and the connecting pipe reaches At the extrusion die head (the temperature at the die head is 190-230°C), the molten resin is compounded with two layers of aluminum foil on the left and right by double-roller extrusion at the die head, and the thickness is obtained by quenching the roll at 80-100°C. 100μm thin film with a width of 1.0m. The heat-sensitive film is then subjected to gamma rays (Co 60 ) irradiation with a dose of 50-80Mrad, the polymer PTC thermosensitive film of the present invention is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com