Method for manufacturing silicon carbide semiconductor device

A semiconductor and silicon carbide technology, which can be used in semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., and can solve problems such as poor characteristics of silicon oxide films.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

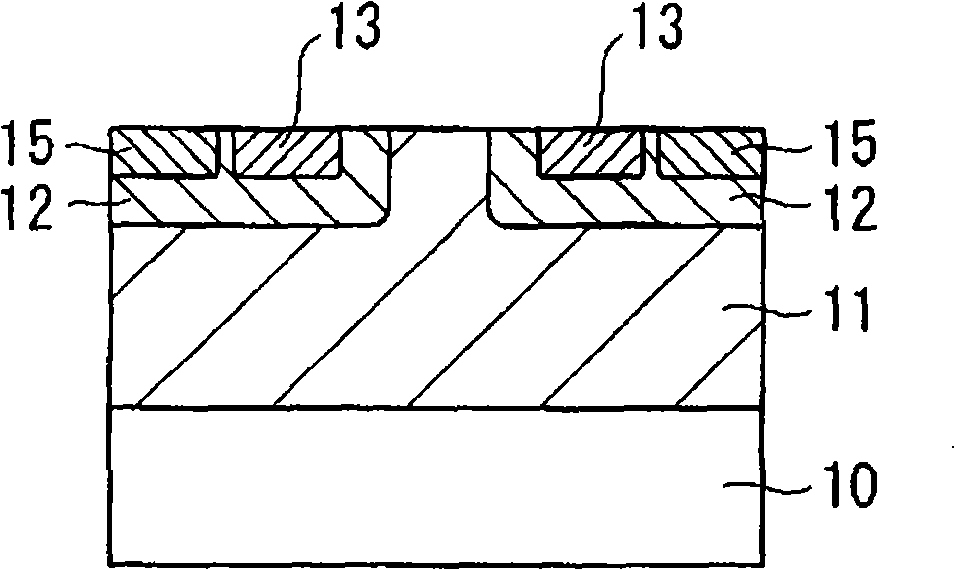

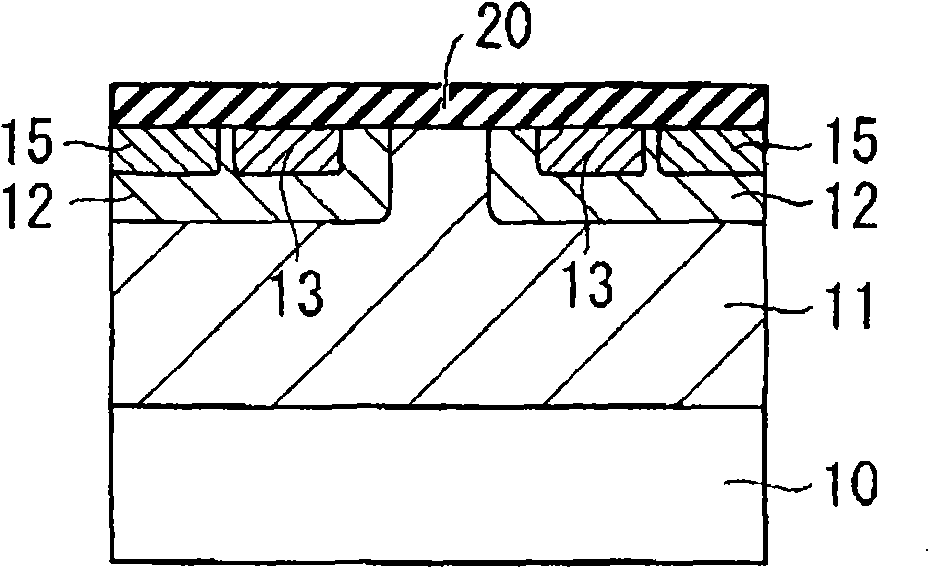

[0029] figure 1 to 6 are cross-sectional views showing steps of manufacturing a MOSFET representing a silicon carbide semiconductor device in the embodiment. although figure 1 to 6 only show two transistor cells representing a part of the vertical MOSFET, but a large number of transistor cells are integrated to constitute one vertical MOSFET.

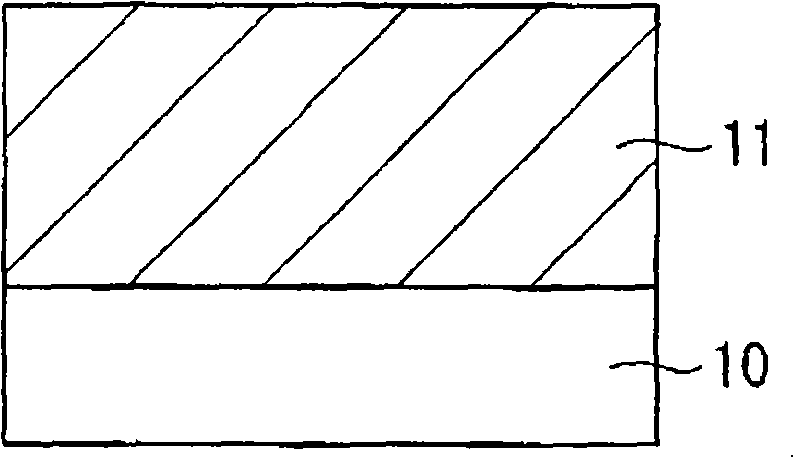

[0030] exist figure 1 In the steps shown, an n-type 4H (hexagonal)-SiC (4 indicates the number of layers stacked in one cycle) substrate 10 is prepared, which has, for example, a resistivity of 0.02 Ωcm and a thickness of 400 μm, and has a thickness in [ The (0001) plane with an inclination angle of about 8° in the 11-20] direction was used as the main surface. Then, using CVD epitaxial growth including in-situ doping, grow on the 4H-SiC substrate 10, for example, containing about 5×10 15 cm -3 concentration of n-type dopant and has an epitaxial growth layer 11 with a thickness of about 10 μm. The outermost surface of the epitaxia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com