Comprehensive utilization process for production waste material of polysilicon

A technology of polysilicon and waste, applied in the direction of silicon compounds, chemical instruments and methods, inorganic chemistry, etc., to achieve the effect of easy realization of technology, high technical content, safe and reliable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

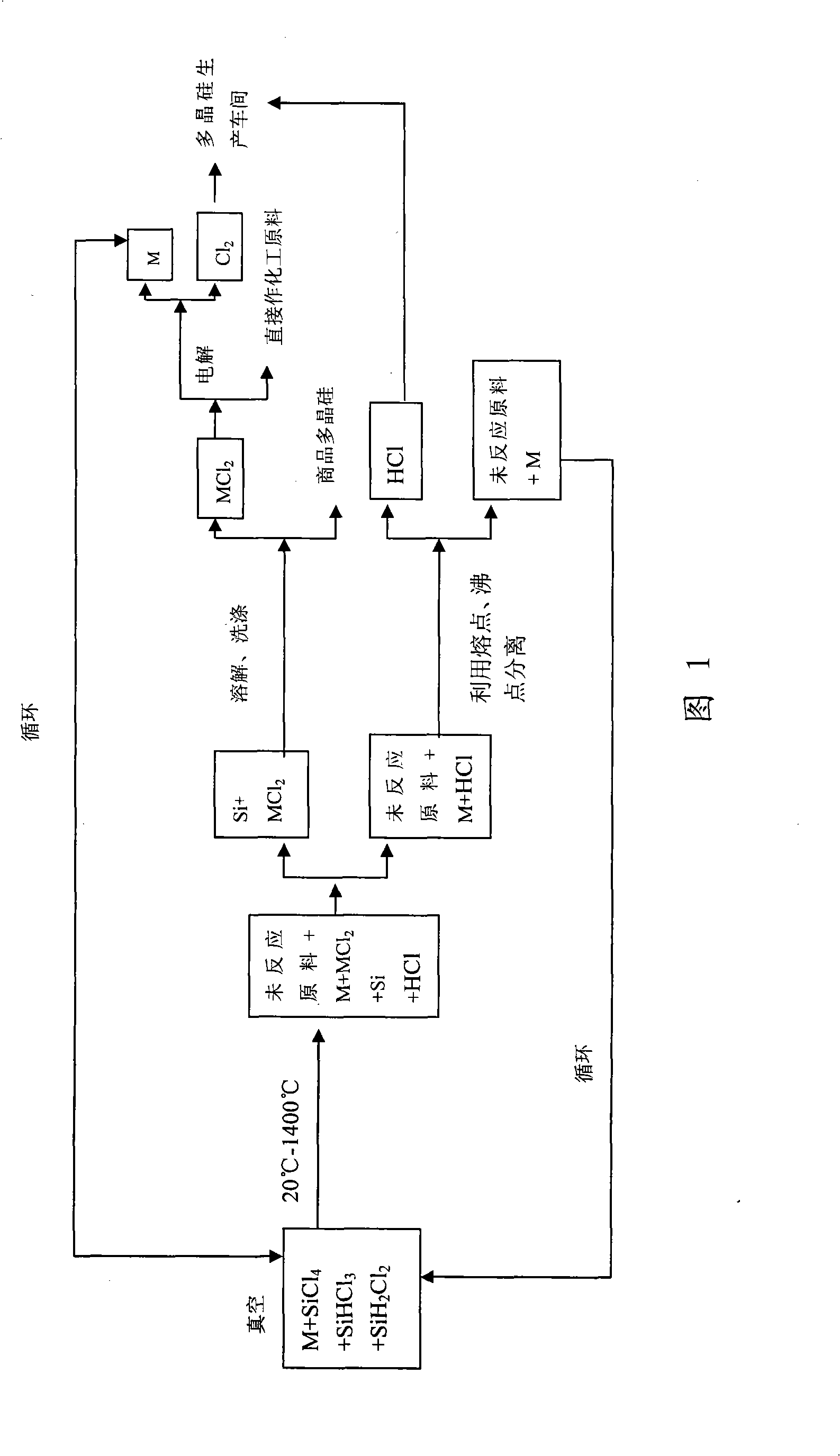

[0031] See accompanying drawing 1 of the description. Get 700 grams of polysilicon production waste and 370 sodium and place it in a sealed container, vacuumize to 10 -2 Pa, heat to about 50°C, keep warm for about 2 hours, the remaining solid in the container is polysilicon and chloride, dissolve the solid with pure water, filter, wash and dry the filter residue, and the solid substance obtained is polysilicon, which weighs 100.3 grams ; After the filtrate is purified, the solid obtained by distillation is sodium chloride, and the obtained sodium chloride is mixed with anhydrous barium chloride and anhydrous calcium chloride, put into an electrolytic cell, heated to about 700 ° C, and the solid is in a molten state. Through low-voltage, high-current direct current, the floating matter on the upper part of the cathode is metal sodium, which can be exported and cooled to obtain solid metal sodium, which can be returned to the first step of the present invention for use; the anod...

Embodiment 2

[0033] See accompanying drawing 1 of the description. Get 700 grams of polysilicon production waste and 350 calcium and place it in a sealed container, vacuumize to 10 -2 Pa, heat to about 150°C, keep warm for about 2 hours, the remaining solid in the container is polysilicon and chloride, dissolve the solid with pure water, filter, wash and dry the filter residue, and the solid substance obtained is polysilicon, which weighs 101.0 grams ; After the filtrate is purified, the solid obtained by distillation is calcium chloride, and the obtained calcium chloride is mixed with 5% cryolite, put into the electrolytic cell, heated to a molten state, and passed through low-voltage, high-current direct current, and the upper melt of the cathode floats The substance is calcium metal, which can be exported and cooled to obtain solid calcium metal, which can be used in the first step of the present invention; the anode produces chlorine gas, which can be collected and used as a raw materi...

Embodiment 3

[0035] See accompanying drawing 1 of the description. Take 700 grams of polysilicon production waste and 560 grams of zinc and place it in a sealed container, vacuumize to 10 -3Pa, heated to about 1000°C, heat-retained for about 2.5 hours, and exported the remaining gas in the container with heat preservation. The remaining solid in the container was polysilicon, which was measured as 102.9 grams; the temperature of the exported product was controlled at about 810°C, and the unreacted gas was separated. Zinc; then export the residue and control the temperature at about 350°C to realize the separation of zinc chloride. Lead the separated zinc chloride liquid into the electrolytic cell, add 5% sodium chloride and calcium chloride as flux, heat to melt, and pass low-voltage, high-current direct current, and the cathode produces zinc, which can be returned to The first step of the present invention is to utilize it; the anode generates chlorine gas, which can be collected and use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com