Process for extracting xanthohumol from lupulus

A technology of xanthohumol and hops is applied in the directions of pharmaceutical formulations, medical preparations containing active ingredients, separation/purification of carbonyl compounds, etc. The effect of high sample recovery, high purity and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

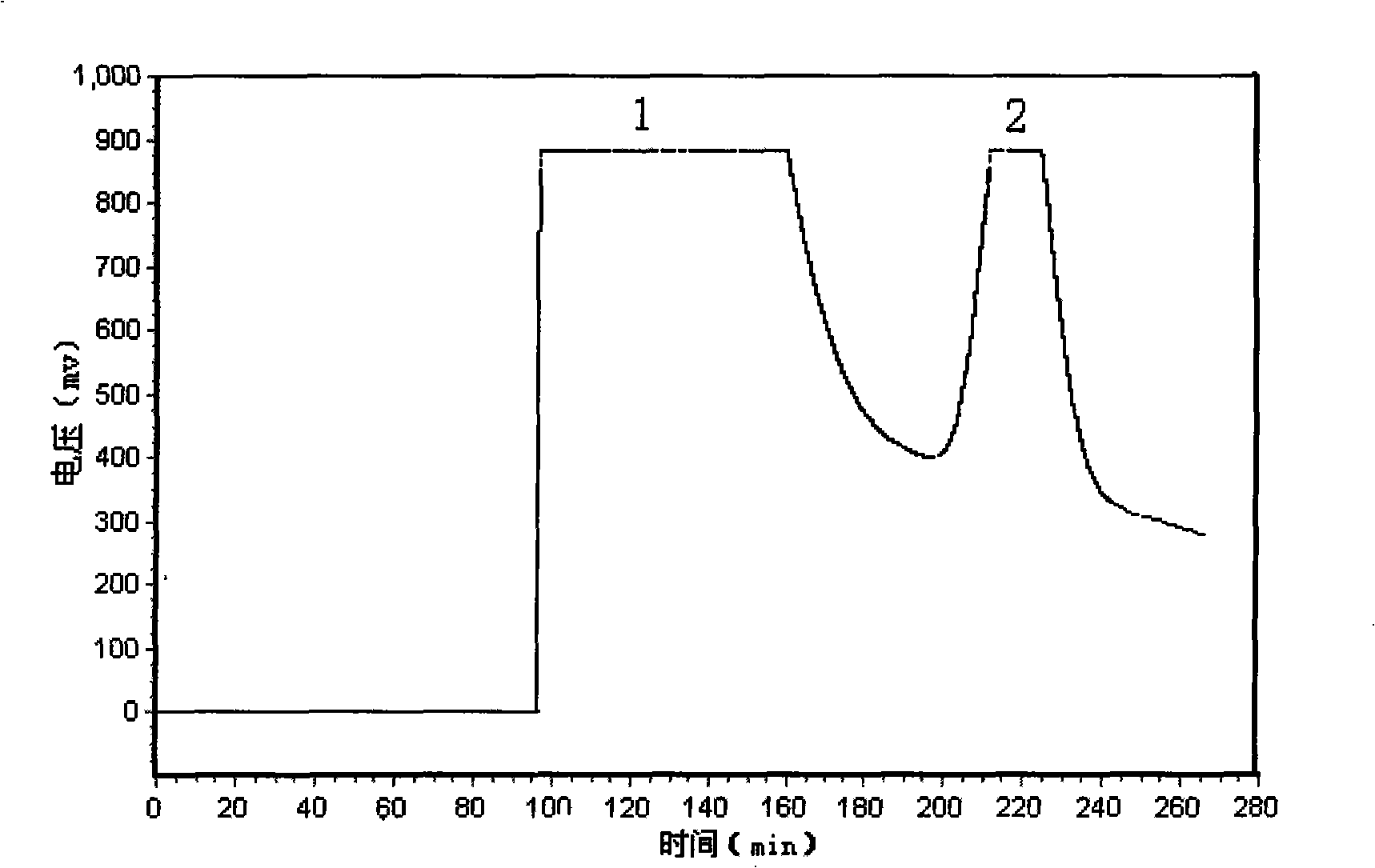

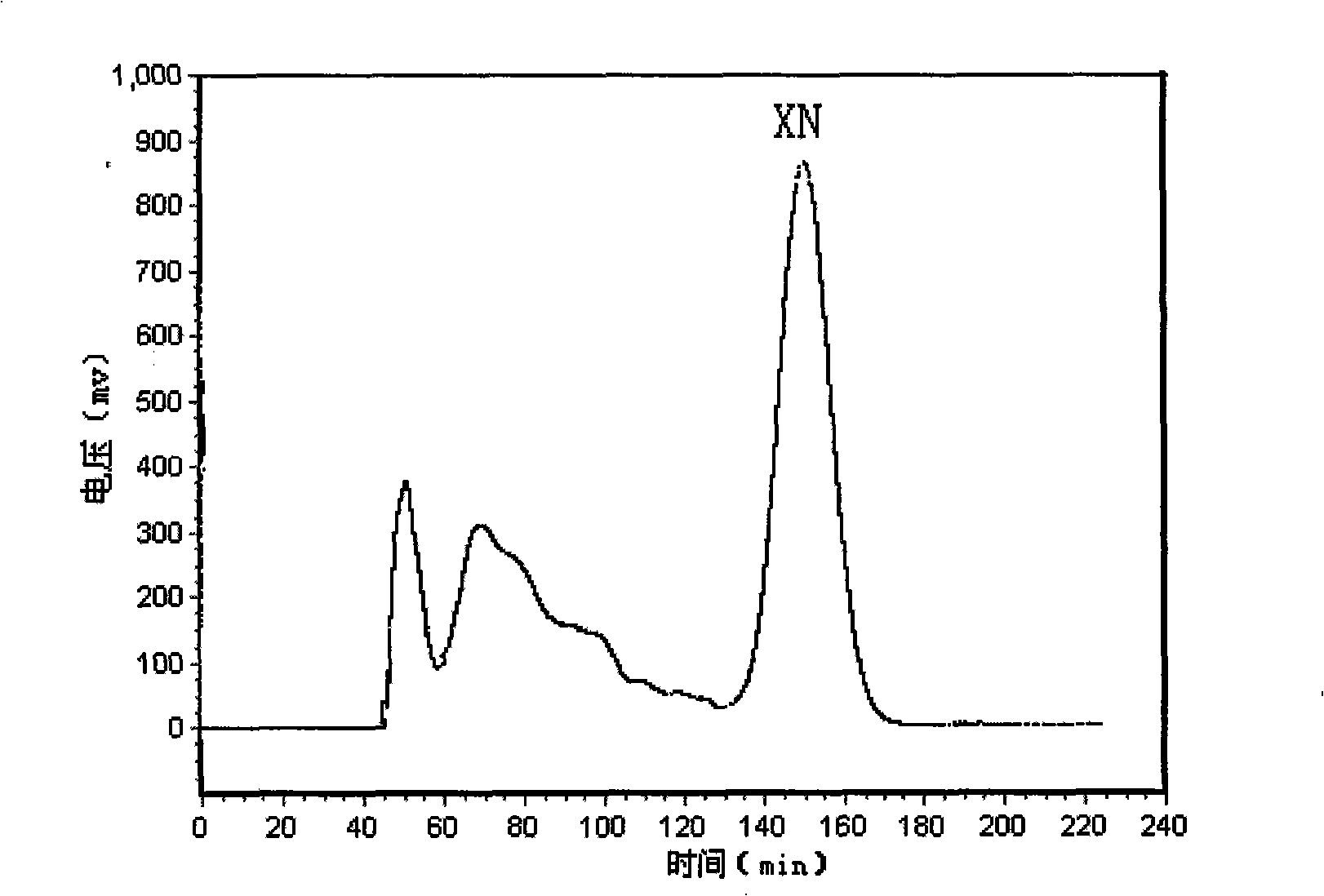

Method used

Image

Examples

Embodiment 1

[0025] (1) Get the brewing particle hops of the brewery and pulverize into powder with a plant pulverizer;

[0026] (2) Use 1000ml of petroleum ether (boiling range 60-90°C) to reflux the above-mentioned 100g of crushed hops in a water bath to extract the fat-soluble components in the hops. The extraction temperature is 63°C, the extraction time is 45 minutes, and the extraction is repeated twice, and the oil is separated by filtration. ether solution to obtain defatted hops;

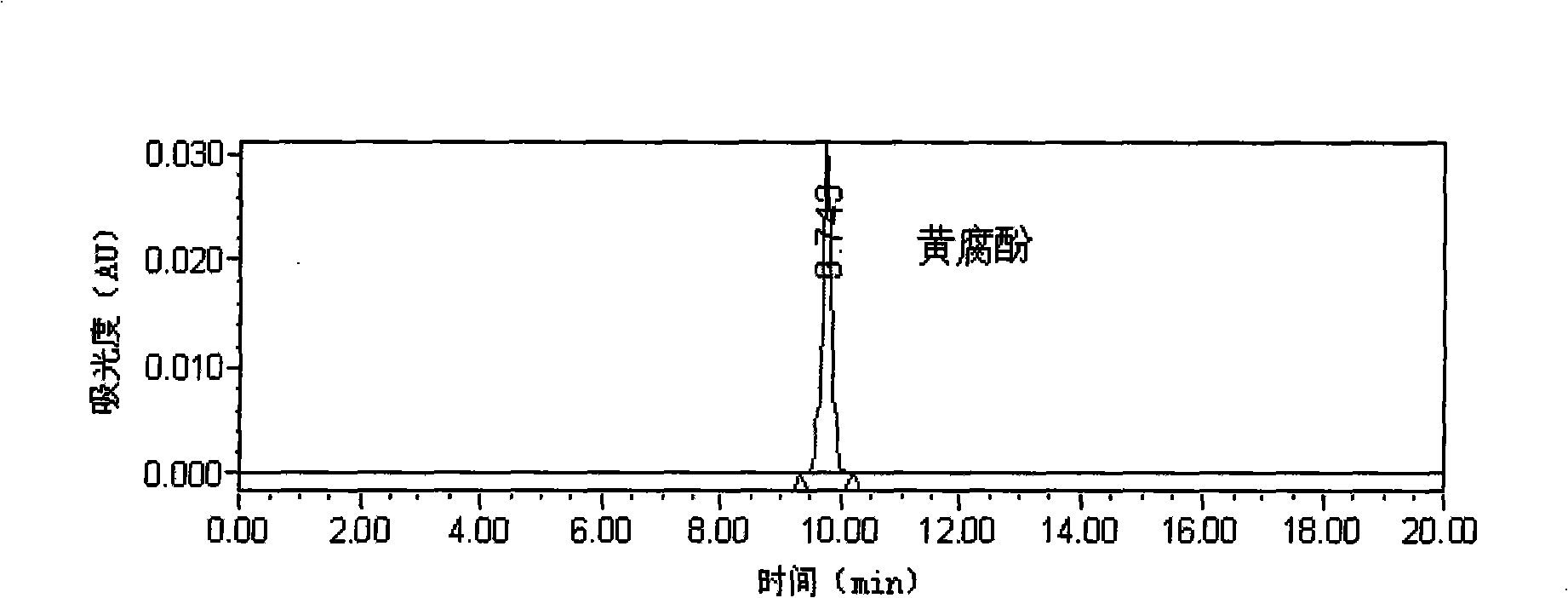

[0027] (3) 1000ml of 95% (v / v) ethanol was added to defatted hops to extract xanthohumol ultrasonically, the extraction temperature was 60°C, the extraction time was 40 minutes, the ultrasonic power was 200W, and the extraction was repeated twice. Filtrate, combine the extracts, and concentrate under reduced pressure to a thick paste; (after the thick paste is vacuum-dried, the xanthohumol content of the thick paste is 4.09% as determined by HPLC).

[0028] (4) Add 300ml of ethyl acetate to the above t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com