Surface activity microballoons, preparation and application thereof

A technology of surface activity and microspheres, which is applied in nonlinear optics, instruments, optics, etc., can solve the problems of shortening the service life of electronic paper by electrophoresis, and achieve the effects of reducing consumption and pollution, prolonging service life and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Example 1: Utilize allyl methacrylate to synthesize a cross-linked cue ball polymer with a lower limit of dosage. Its formula is listed in table 1:

[0058] Table 1

[0059]

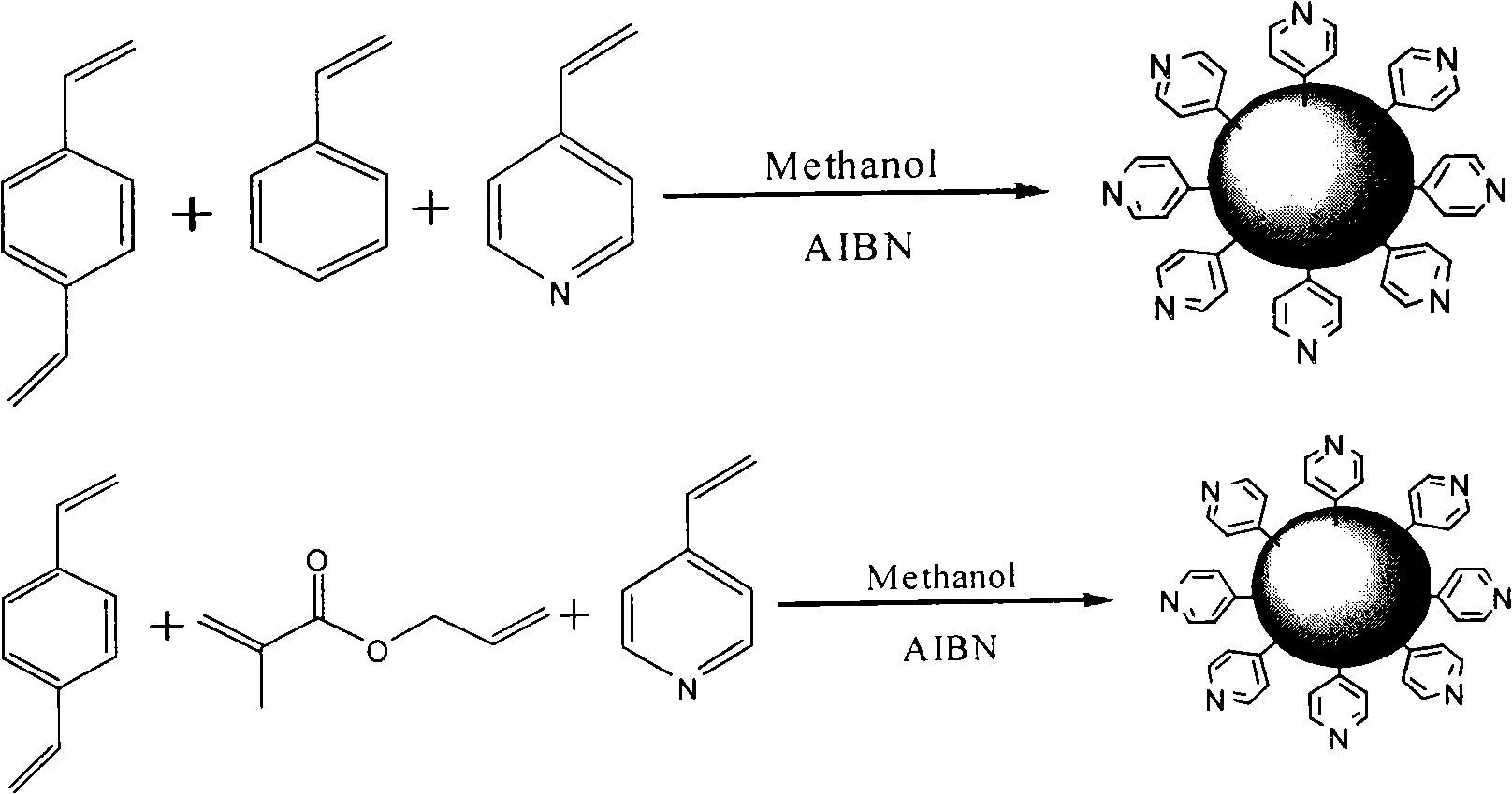

[0060] Azobisisobutyronitrile, divinylbenzene, allyl methacrylate, 4-vinylpyridine (or 2-vinyl pyridine) were successively dissolved in methanol and stirred to dissolve. After bubbling argon gas for 30 minutes, keep the stirring speed at 300rpm-400rpm, start heating and raise the temperature to 70°C. Keep the temperature and speed at 70°C for 12 hours. After cooling, the reaction ends.

[0061] The product was suction-filtered to obtain a solid, which was washed with ethanol, suction-filtered three times, and finally dried.

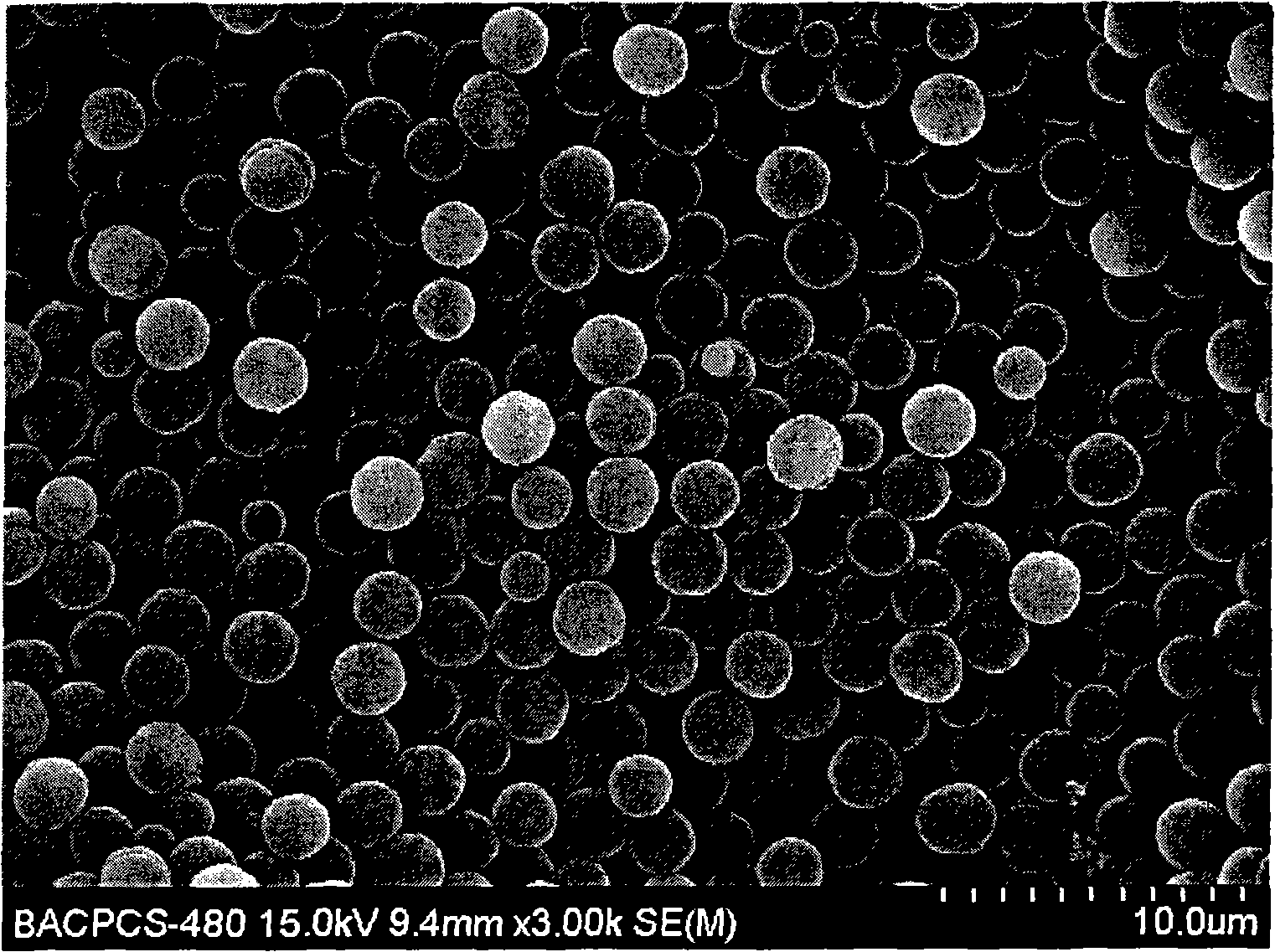

[0062] like figure 1 Shown is a scanning electron micrograph of the surface-active microsphere parent ball obtained in Example 1 of the present invention.

[0063] The photo is obtained by spraying gold on the white powder, and then taking pictures with a Hitachi S-...

Embodiment 2

[0075] Example 2: Utilize allyl methacrylate to synthesize a cross-linked cue ball polymer with an intermediate amount. Its formula is listed in table 2:

[0076] Table 2

[0077]

[0078] The synthesis process is similar to Example 1.

Embodiment 3

[0079] Example 3: Utilizing allyl methacrylate to synthesize a cross-linked cue ball polymer with an upper limit. Its formula is listed in table 3:

[0080] The synthesis process is similar to Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Emission current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com