Preparation method of hydroxyapatite microsphere

A technology of hydroxyapatite and microspheres, which is applied in the field of preparation of hydroxyapatite microspheres, can solve the problems of high cost, complicated production process, unfavorableness and the like, achieves large specific surface and pores, good application prospects, easy to obtain Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] In the first step, at 0.6 mol / L Ca(OH) 2 Add 100ml of the suspension into a three-necked flask placed on an electric heating mantle, and add 10ml of 0.3 mol / liter EDTA ammonium salt under stirring;

[0024] In the second step, 20ml of 0.36 mol / L (NH 4 ) 2 HPO 4 and 80ml of 0.6 mol / l NH 4 HCO 3 After the solution is mixed evenly, it is gradually added dropwise into the three-necked flask, the dropwise addition time is 120min, and the stirring speed is 800r / min;

[0025] In the third step, the three-necked flask was heated to 50°C, and 80ml of 0.36 mol / L H 3 PO 4 solution, the dropping time is 150min, and after the dropping is completed, the reaction is continued for 300min to obtain hydroxyapatite slurry;

[0026] In the fourth step, the slurry is naturally cooled overnight, filtered, washed twice with deionized water, and then dried in a vacuum oven at 50°C for 24 hours, and ground after cooling to obtain hydroxyapatite microspheres .

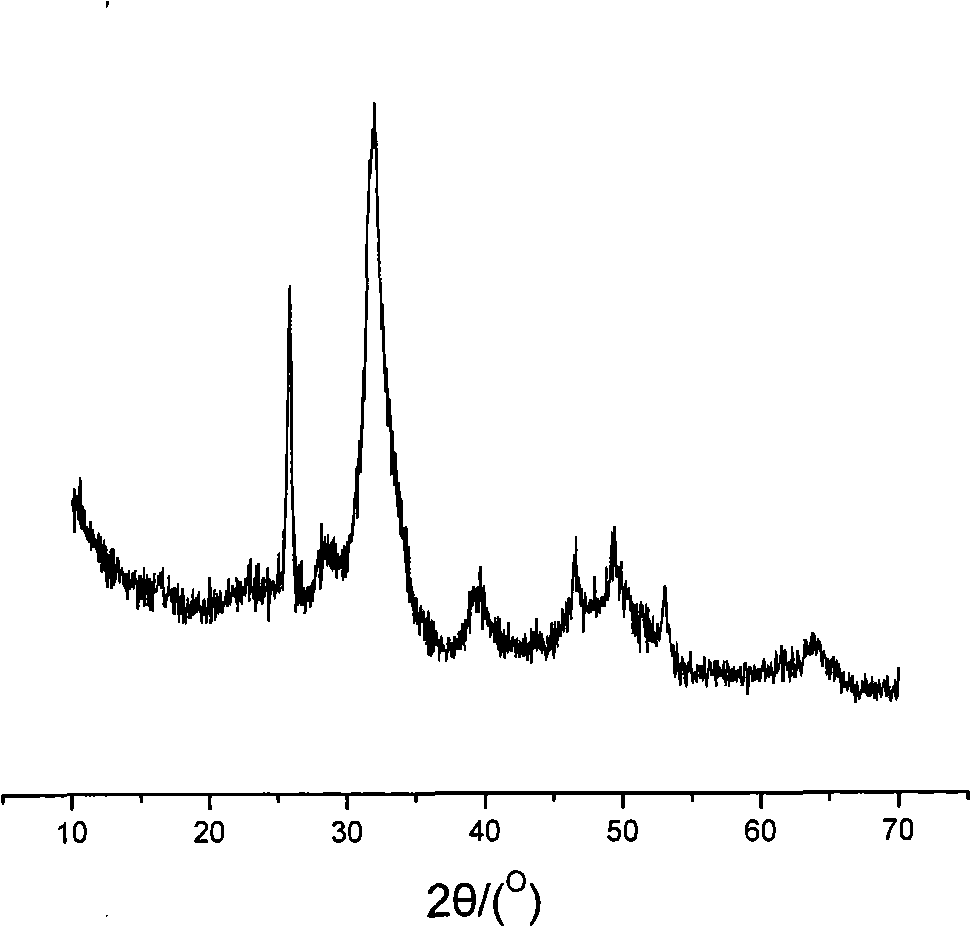

[0027] The XRD figure an...

Embodiment 2

[0029] In the first step, at 0.4 mol / L Ca(OH) 2 Add 100ml of the suspension into a three-neck flask placed on an electric heating mantle, and add 5ml of 0.3 mol / liter EDTA ammonium salt under stirring;

[0030] In the second step, 50ml of 0.24 mol / L (NH 4 ) 2 HPO 4 and 50ml of 0.4 mol / l NH 4 HCO 3 After the solution is mixed evenly, it is gradually added dropwise into the three-necked flask, the dropping time is 120min, and the stirring speed is 500r / min;

[0031] In the third step, the three-neck flask was heated to 80°C, and 50ml of 0.24 mol / L H 3 PO 4 solution, the dropping time is 100min, and after the dropping is completed, the reaction is continued for 200min to obtain hydroxyapatite slurry;

[0032] In the fourth step, the slurry is naturally cooled overnight, filtered, washed twice with deionized water, and then dried in a vacuum oven at 50°C for 24 hours, and ground after cooling to obtain hydroxyapatite microspheres .

[0033]After testing: the phase of the ...

Embodiment 3

[0035] In the first step, at 0.6 mol / L Ca(OH) 2 Add 100ml of the suspension into a three-necked flask placed on an electric heating mantle, and add 10ml of 0.3 mol / liter EDTA ammonium salt under stirring;

[0036] In the second step, 70ml of 0.36 mol / liter (NH 4 ) 2 HPO 4 and 30ml of 0.6 mol / l NH 4 HCO 3 After the solution is mixed evenly, it is gradually added dropwise into the three-necked flask, the dropping time is 120min, and the stirring speed is 900r / min;

[0037] In the third step, the three-necked flask was heated to 80°C, and 30ml of 0.36 mol / L H 3 PO 4 solution, the dropping time is 60min, and after the dropping is completed, the reaction is continued for 300min to obtain hydroxyapatite slurry;

[0038] In the fourth step, the slurry was naturally cooled overnight, washed twice with deionized water, then dried in a vacuum oven at 50° C. for 24 hours, and ground after cooling to obtain hydroxyapatite microspheres.

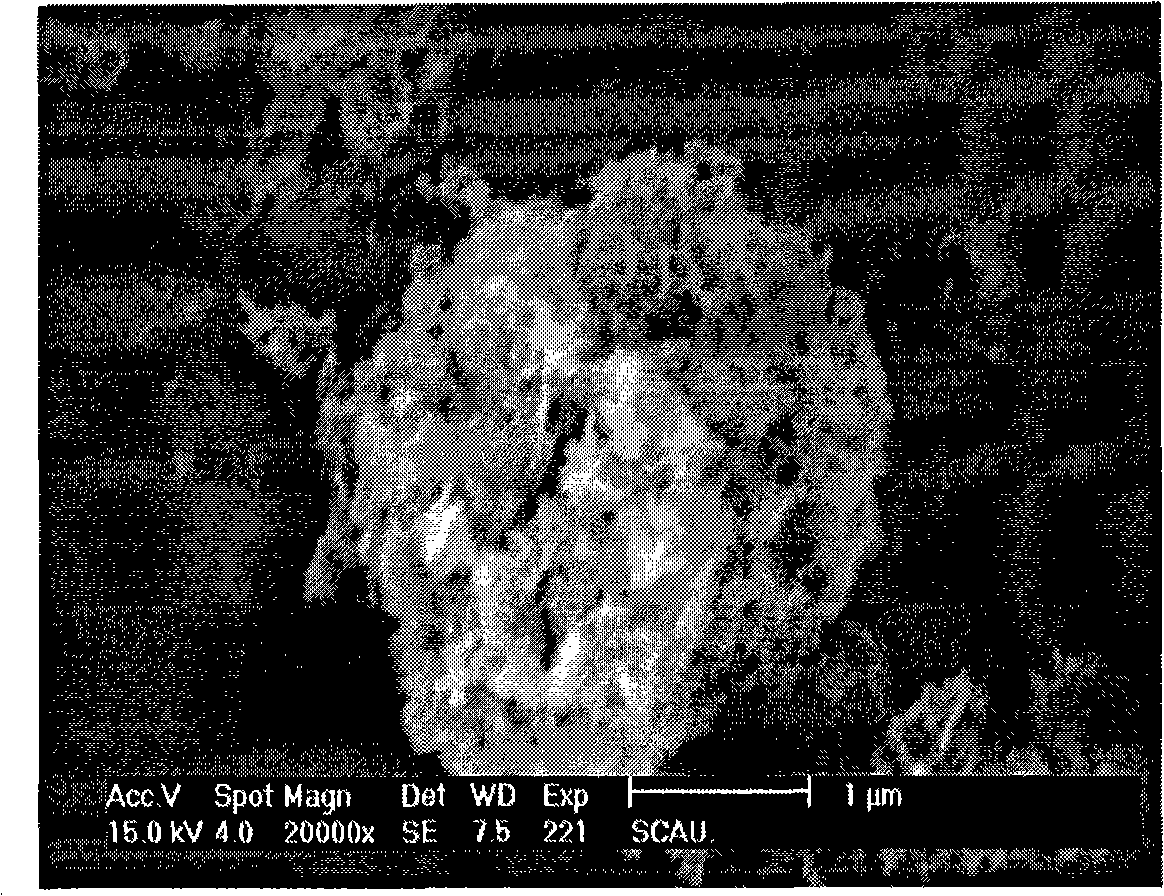

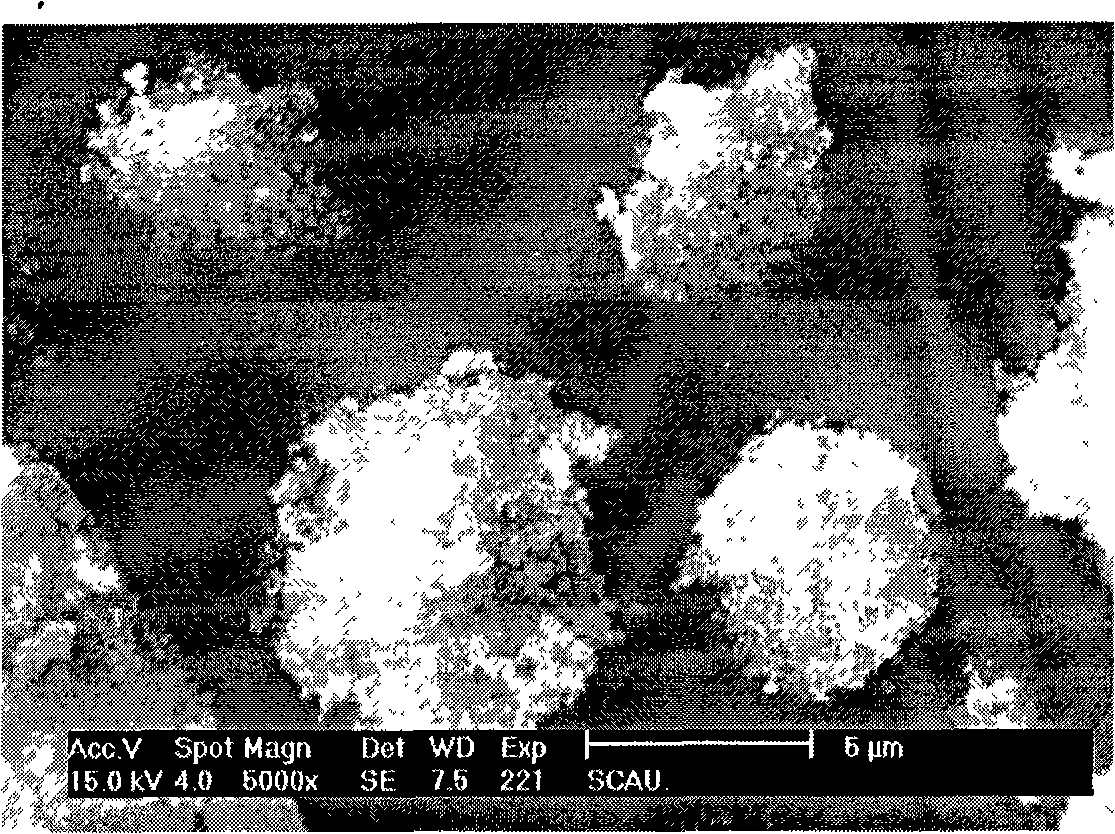

[0039] The SEM image of the obtained hydrox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com