Cell separation microchip based on silicon structure on insulators

A silicon-on-insulator, microchip technology, applied in the field of microchips for cell screening and separation, can solve the problems of weak electric field strength and electric field gradient, weak anti-corrosion, weak anti-oxidation ability, affecting the biological activity of cells, etc., so as to reduce physical damage. , low cost, mature processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

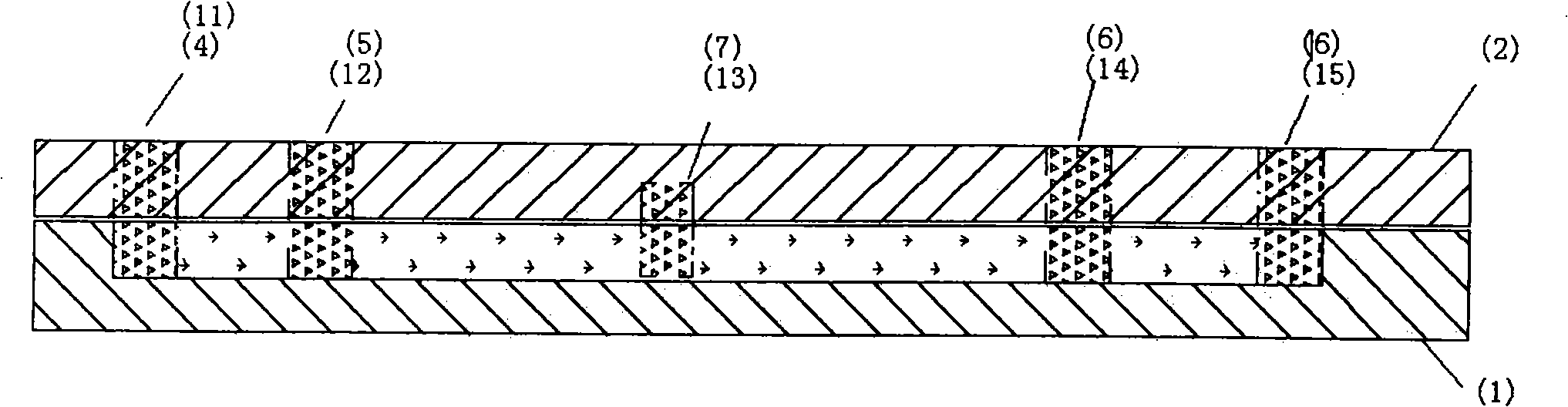

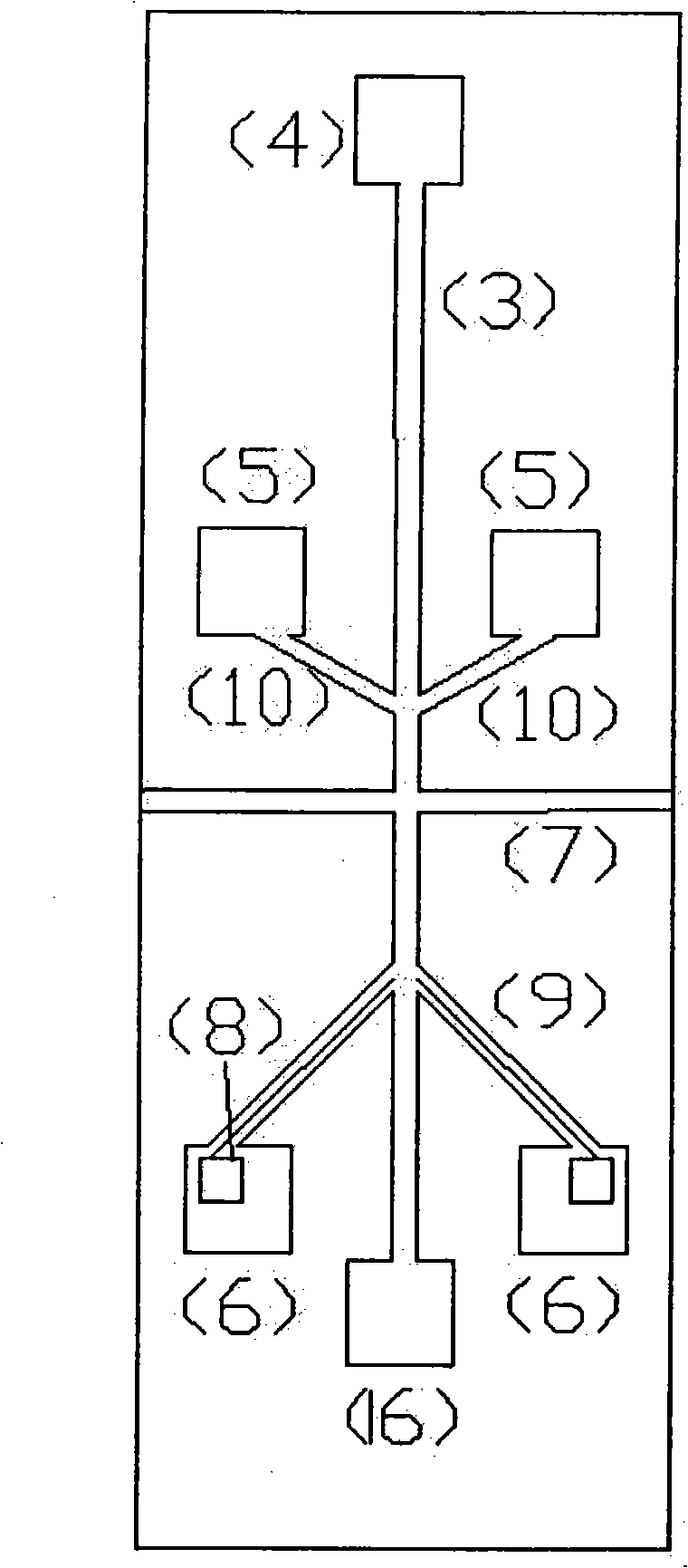

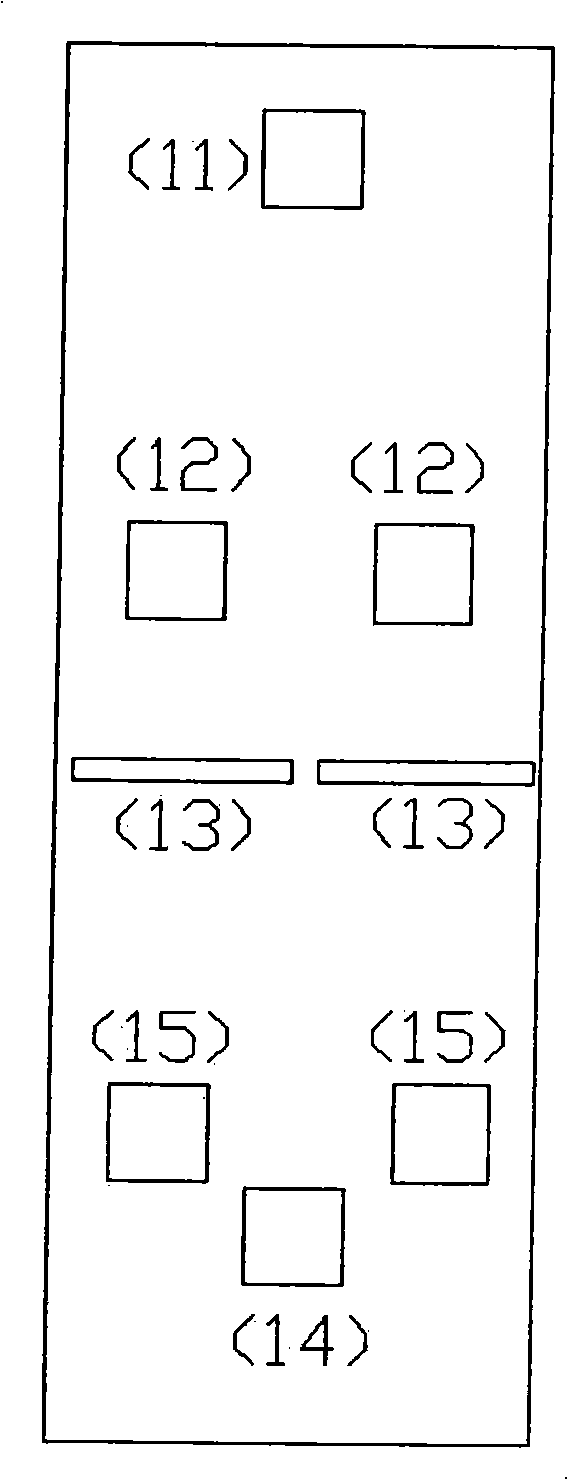

[0043] see figure 1 , 2 and 3, the microchip is composed of two layers bonded to each other, layer I is the channel layer 1, and layer II is the cover layer 2. The channel layer is a microstructure formed by etching grooves on the SOI silicon wafer using MEMS processing technology. The channel layer 1 has a main microchannel 3, a microchannel 9 connecting the main microchannel and the fusion cell pool, a sheath fluid channel 10, and a sample Pool 4, sheath flow pool 5, waste liquid pool 16, fusion cell pool 6, optical fiber groove 7 and microelectrode pair 8 structures, the sample pool 4 on the channel layer 1 is used for the storage of the sample liquid before screening; the main microchannel 3. The microchannel 9 and the sheath fluid channel 10 are kept unblocked for sample (cell suspension or solution) flow, and the optical fiber located in the optical fiber groove 7 provides an optical detection path; the microelectrode pair 8 realizes cell screening. The cover layer 2 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com