Solar cell and method of manufacturing the same

A technology of solar cells and electrodes, applied in circuits, photovoltaic power generation, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

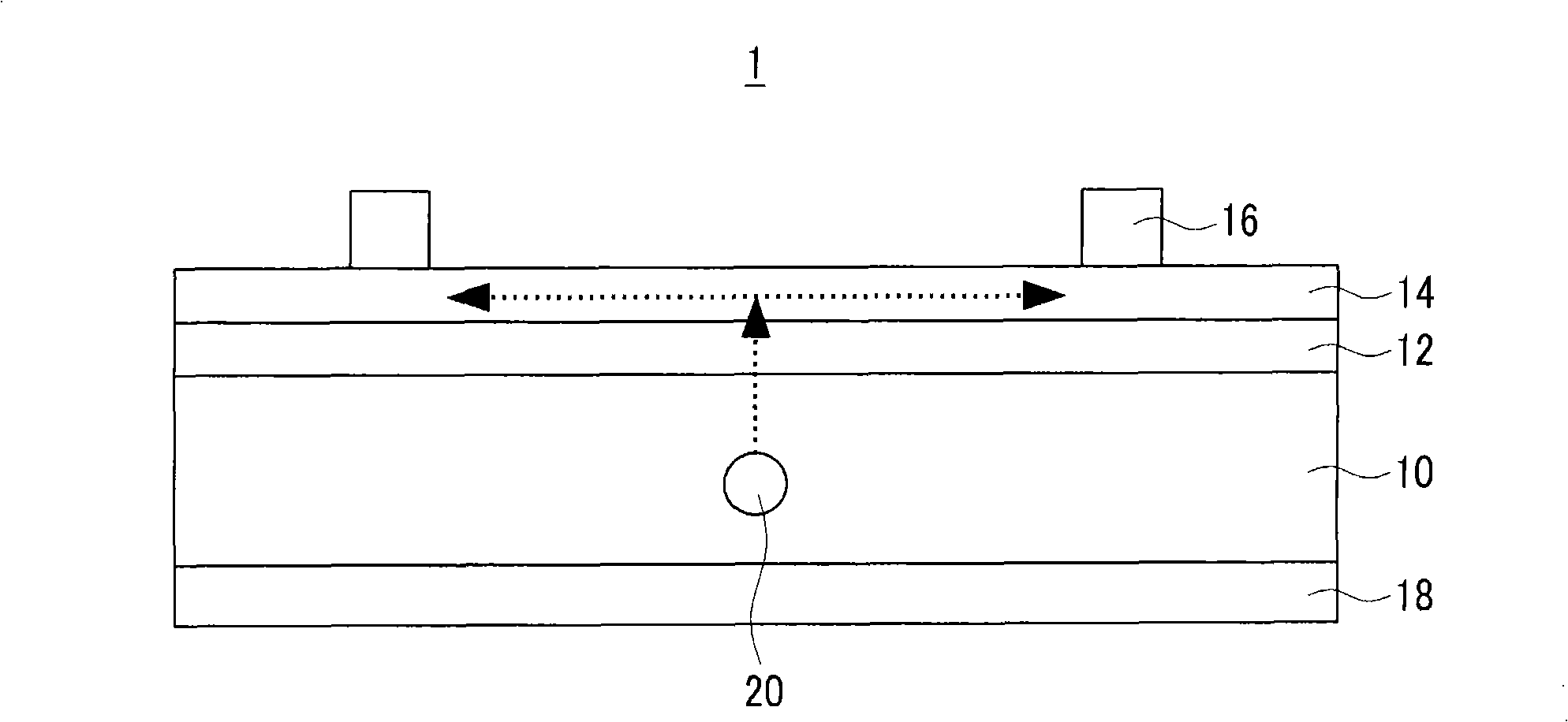

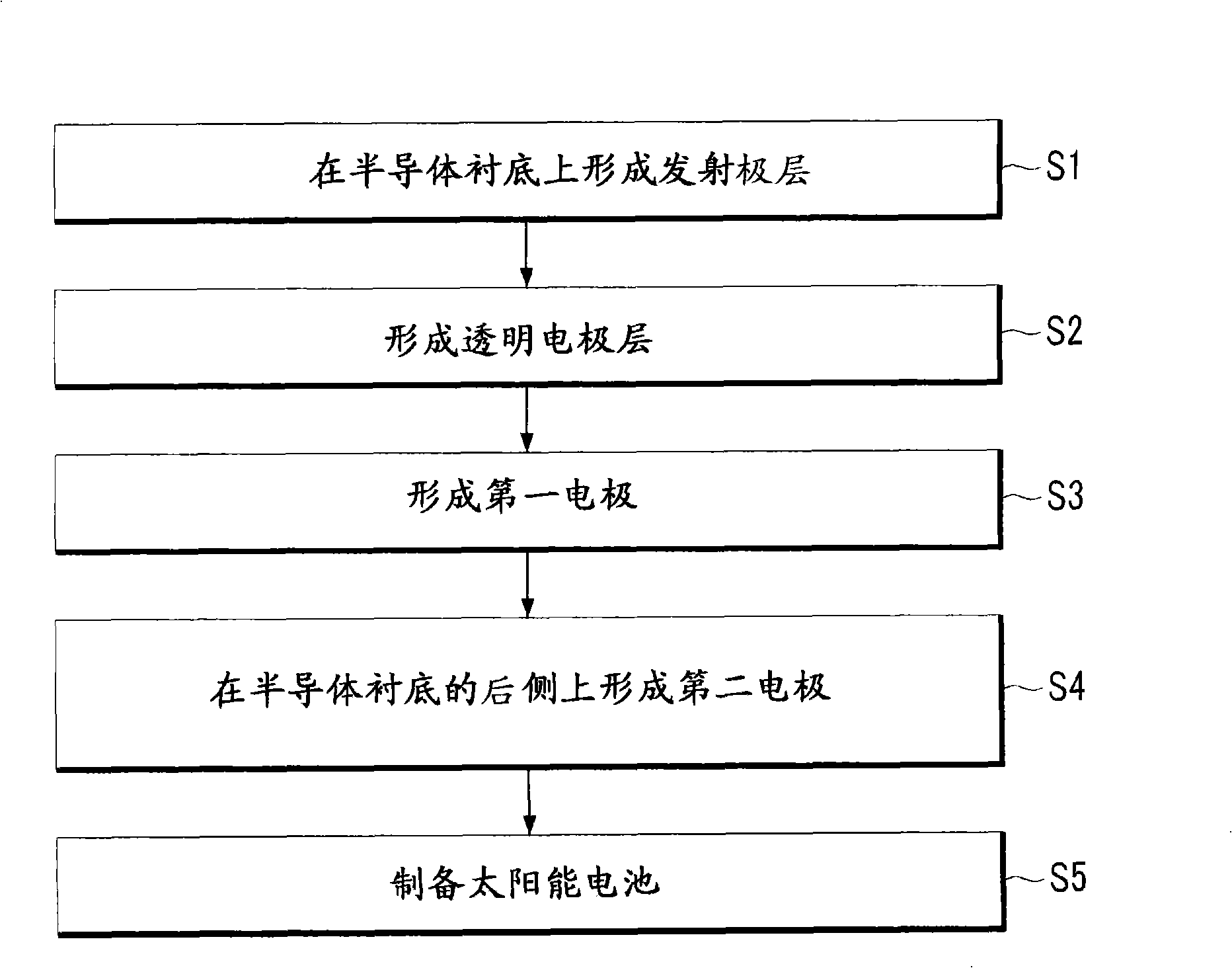

[0094] On one side of a boron-doped p-type silicon substrate (resistivity: 1Ω·cm), a 0.45 μm-thick emitter layer having phosphorous-doped n-type silicon was arranged. Boron at 1.5 x 10 16 / cm 3 amount doped into the p-type silicon substrate. The surface resistance of the emitter layer including n-type silicon was 50Ω per square.

[0095] Then, a conductive transparent electrode layer with a thickness of 80 nm was arranged on the emitter layer by sputtering.

[0096] An Al-containing paste was screen printed onto the other side of the p-type silicon substrate (ie, the side without the emitter layer). In addition, a p-type silicon substrate with a conductive transparent electrode layer was screen-printed with Ag-containing paste every 6 mm to form a pattern, and then sintered at 400 °C for 30 seconds to simultaneously (or parallel) form the first and second electrode, and then prepare a solar cell.

[0097] The emitter layer at the corners of the solar cell is laser removed...

example 2

[0099] On one side of a boron-doped p-type silicon substrate (resistivity: 1Ω·cm), a 0.3 μm-thick emitter layer with phosphorus-doped n-type silicon was arranged. Here, boron in 1.5×10 16 / cm 3 The amount is doped on the p-type silicon substrate. The surface resistance of the emitter layer including n-type silicon was 100Ω per square.

[0100] Then, on this emitter layer, an 80 nm-thick conductive transparent electrode layer was arranged using indium tin oxide (ITO) by a sputtering method.

[0101] Next, an Al-containing paste was screen printed on the other side of the p-type silicon substrate (ie, the side without the emitter layer). In addition, the p-type silicon substrate with the conductive transparent electrode layer was screen-printed with Ag-containing paste every 2.5 mm to form a pattern, and then fired at 400° C. for 30 seconds to simultaneously (or in parallel) ) to form the first and second electrodes, and then prepare a solar cell.

[0102] The emitter layer...

example 3

[0104] On one side of a boron-doped p-type silicon substrate (resistivity: 1Ω·cm), a phosphorous-doped n-type silicon emitter layer of 0.3 μm thick was arranged. Here, boron in 1.5×10 16 / cm 3 The amount is doped on the p-type silicon substrate. The surface resistance of the emitter layer including n-type silicon was 100Ω per square.

[0105] Then, on this emitter layer, an 80 nm-thick conductive transparent electrode layer was arranged using indium tin oxide (ITO) by a sputtering method.

[0106] An Al-containing paste was screen printed on the other side of the p-type silicon substrate (ie, the side without the emitter layer). In addition, the p-type silicon substrate with the conductive transparent electrode layer was screen-printed with Ag-containing paste every 6 mm to form a pattern, and then fired at 400° C. for 30 seconds to simultaneously (or in parallel) The first and second electrodes are formed to finally produce a solar cell.

[0107] The emitter layer at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com