Manufacturing method of carrollite-based super capacitor electrode plate

A technology of supercapacitor electrode and pyrite, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double layer capacitors, etc., can solve the problems of in-situ preparation of supercapacitor electrode plates, poor connectivity, easy to fall off, etc. To achieve the effect of reducing resistance, good connectivity, and not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

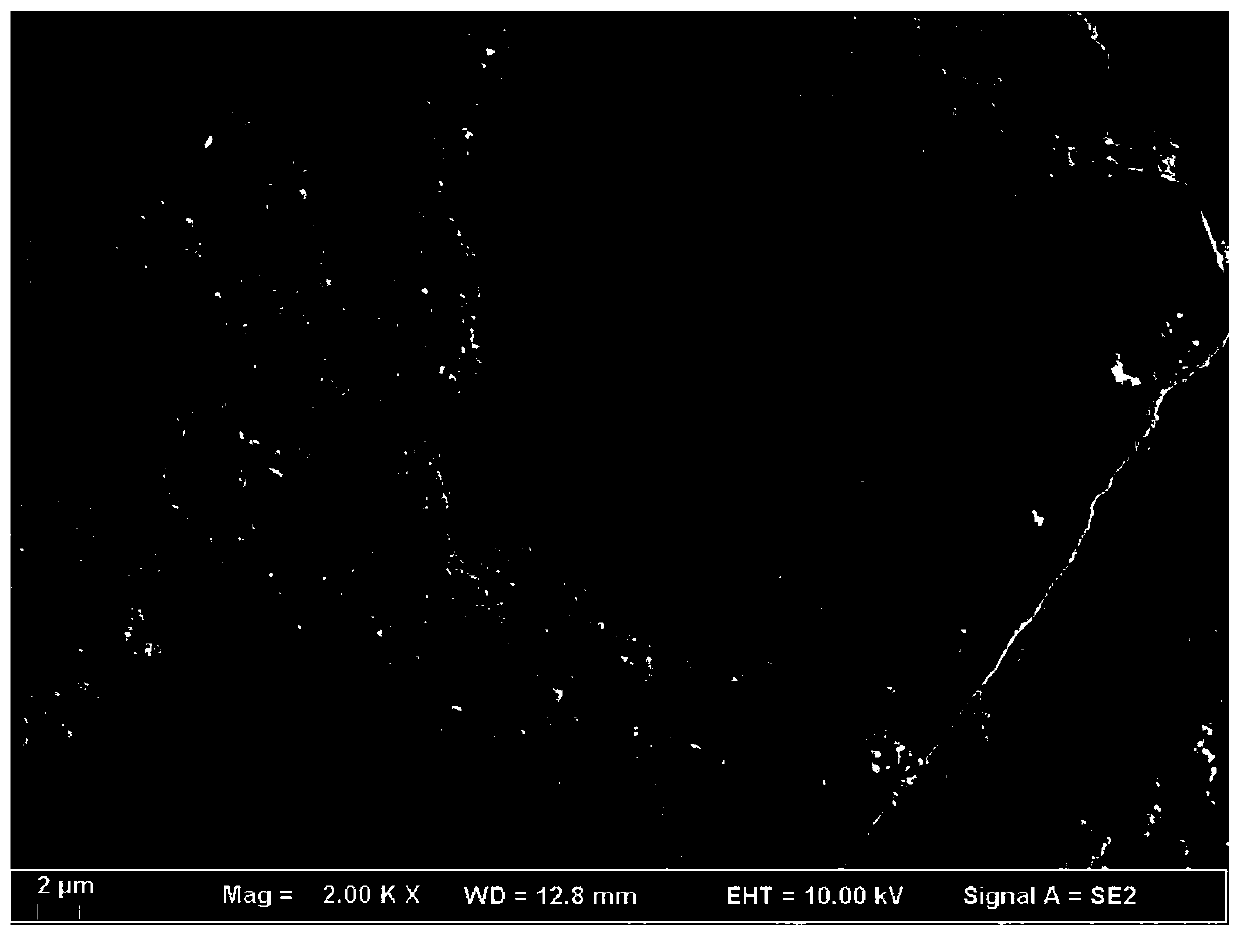

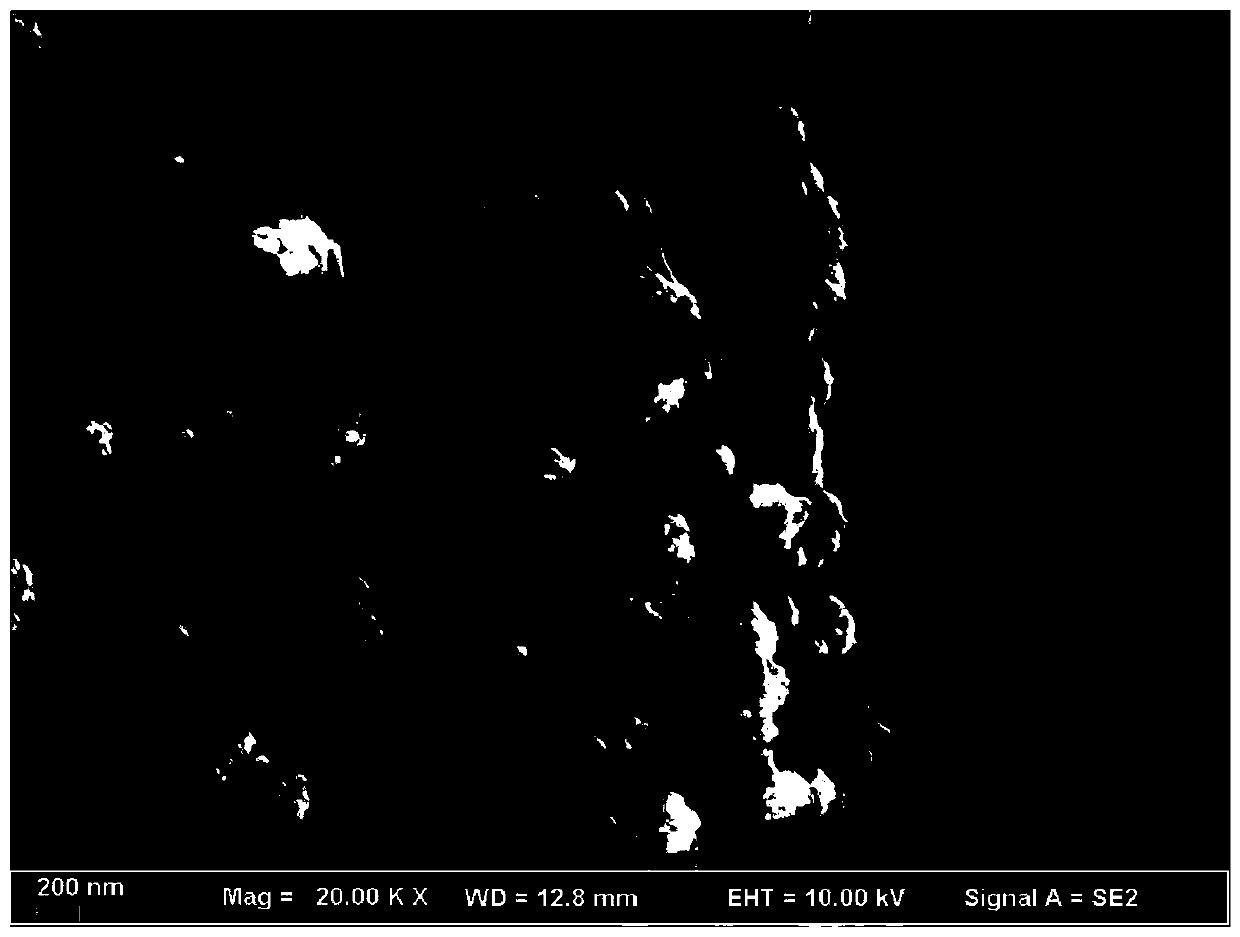

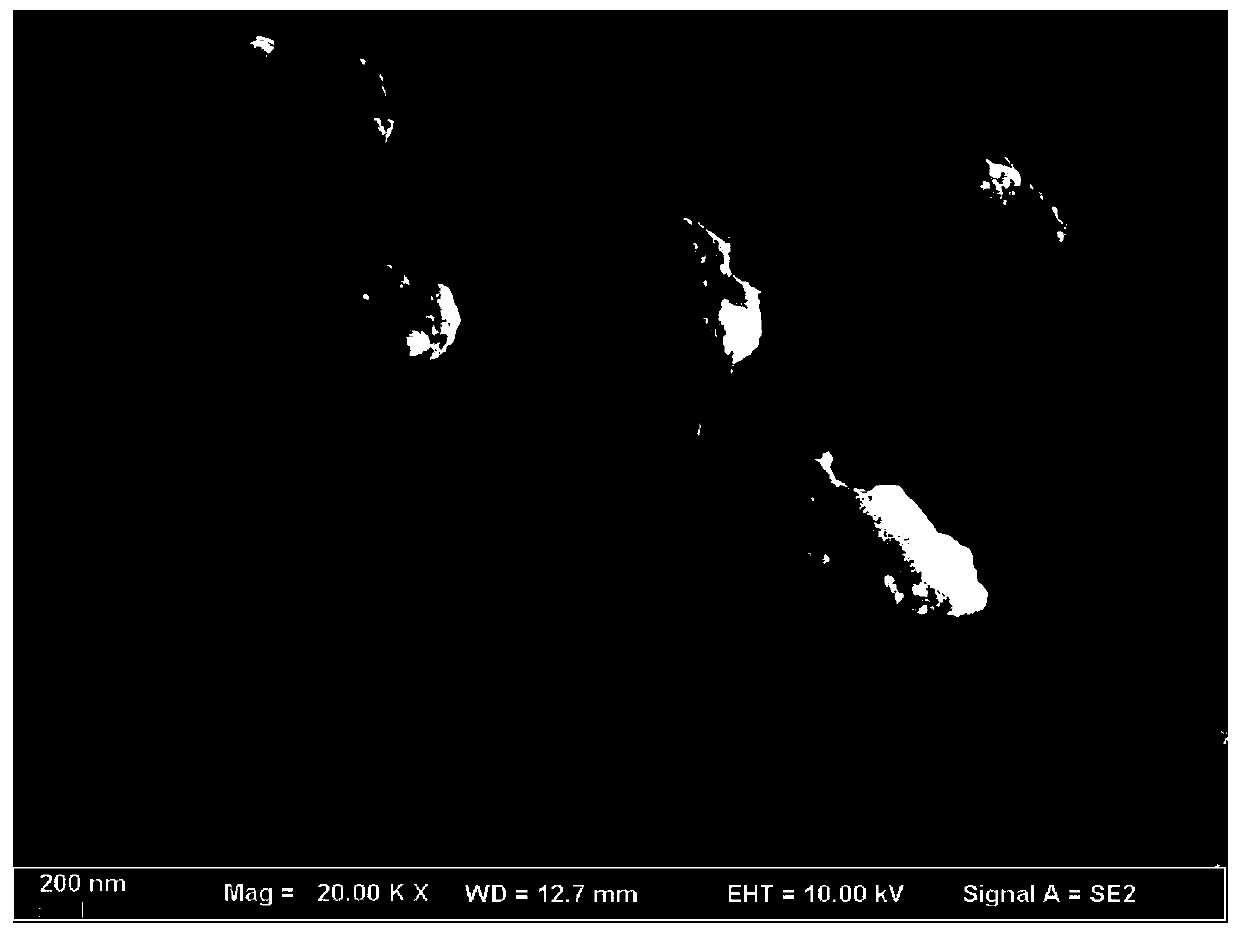

Image

Examples

Embodiment 1

[0026] Embodiment 1 sulfur copper cobalt ore (CuCo 2 S 4 )-based supercapacitor electrode plate preparation

[0027] (1) Preparation of nickel-based current collector

[0028] The first step is to cut the 0.5mm thick nickel foam plate for batteries into a size of 5×5cm;

[0029] Step 2: Soak the foamed nickel plate in acetone, 1M hydrochloric acid, 1M potassium hydroxide, absolute ethanol, and deionized water for 10 minutes;

[0030] In the third step, place the nickel foam plate in a vacuum drying oven and raise the temperature to 70° C., and keep it warm for 4 hours to obtain a clean nickel foam collector.

[0031] (2) Pure CuCo 2 S 4 Active material nano crystal grains are added to absolute ethanol, the mass of absolute ethanol is CuCo 2 S 4 8 to 10 times that of the active material, and then ultrasonically dispersed for 5 to 10 minutes to obtain CuCo 2 S 4 ethanol solution of the active substance;

[0032] (3) Combine the linking agent with the CuCo in the previo...

Embodiment 2

[0037] Embodiment 2 sulfur copper cobalt ore (CuCo 2 S 4 )-based supercapacitor electrode plate preparation

[0038] (1) Preparation of nickel-based current collector

[0039] The first step is to cut the 0.5mm thick nickel foam plate for batteries into a size of 5×5cm;

[0040]In the second step, soak the nickel foam board in acetone, 1M hydrochloric acid, 1M potassium hydroxide, absolute ethanol, and deionized water for 5 minutes;

[0041] In the third step, place the nickel foam plate in a vacuum drying oven and raise the temperature to 80° C., and keep it warm for 2 hours to obtain a clean nickel foam collector.

[0042] (2) Pure CuCo 2 S 4 Active material nano crystal grains are added to absolute ethanol, the mass of absolute ethanol is CuCo 2 S 4 8 to 10 times that of the active material, and then ultrasonically dispersed for 5 to 10 minutes to obtain CuCo 2 S 4 ethanol solution of the active substance;

[0043] (3) Combine the linking agent with the CuCo in th...

Embodiment 3

[0047] Embodiment 3 sulfur copper cobalt ore (CuCo 2 S 4 )-based supercapacitor electrode plate preparation

[0048] (1) Preparation of nickel-based current collector

[0049] The first step is to cut the 0.5mm thick nickel foam plate for batteries into a size of 5×5cm;

[0050] Step 2: Soak the foamed nickel plate in acetone, 1M hydrochloric acid, 1M potassium hydroxide, absolute ethanol, and deionized water for 10 minutes;

[0051] In the third step, place the nickel foam plate in a vacuum drying oven and raise the temperature to 75° C., and keep it warm for 3 hours to obtain a clean nickel foam collector.

[0052] (2) Pure CuCo 2 S 4 Active material nano crystal grains are added to absolute ethanol, the mass of absolute ethanol is CuCo 2 S 4 8 to 10 times that of the active material, and then ultrasonically dispersed for 5 to 10 minutes to obtain CuCo 2 S 4 ethanol solution of the active substance;

[0053] (3) Combine the linking agent with the CuCo in the previo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com