Method for wet method corrosion of Terahertz quantum cascaded laser crestiform structure

A quantum cascade and wet etching technology, which is applied in the structure of optical waveguide semiconductors, semiconductor/solid-state device manufacturing, electrical components, etc., can solve problems such as device open circuit and parasitic resistance, and achieve uniformity of corrosion. Depth of Control for Precise Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] see figure 1 The method for wet etching of the ridge structure of the terahertz quantum cascade laser of the present invention mainly includes the following steps:

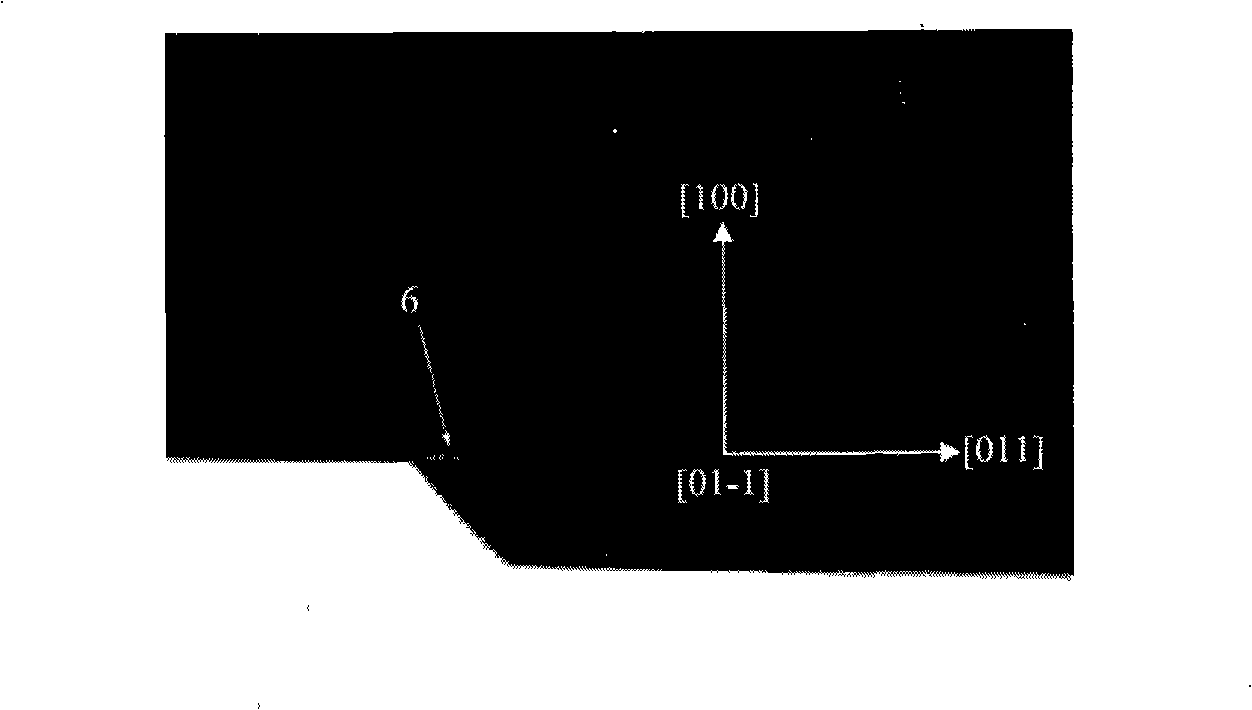

[0016] The first step: preparation before etching, that is, use photolithography to develop the etching mask and hard film, for example, first use S6809 photoresist as the etching mask, so that the strip edges of the mask plate are parallel to the terahertz quantum cascade The [011] crystal orientation of the laser device material, wherein the substrate crystal orientation can be calibrated using the European-Japanese standard (EJ option), and then the terahertz quantum cascade laser device material is baked in an oven at 120°C for 20-30 minutes to Complete the hard film.

[0017] Step 2: before etching, remove the oxide film on the surface of the device material with dilute hydrochloric acid.

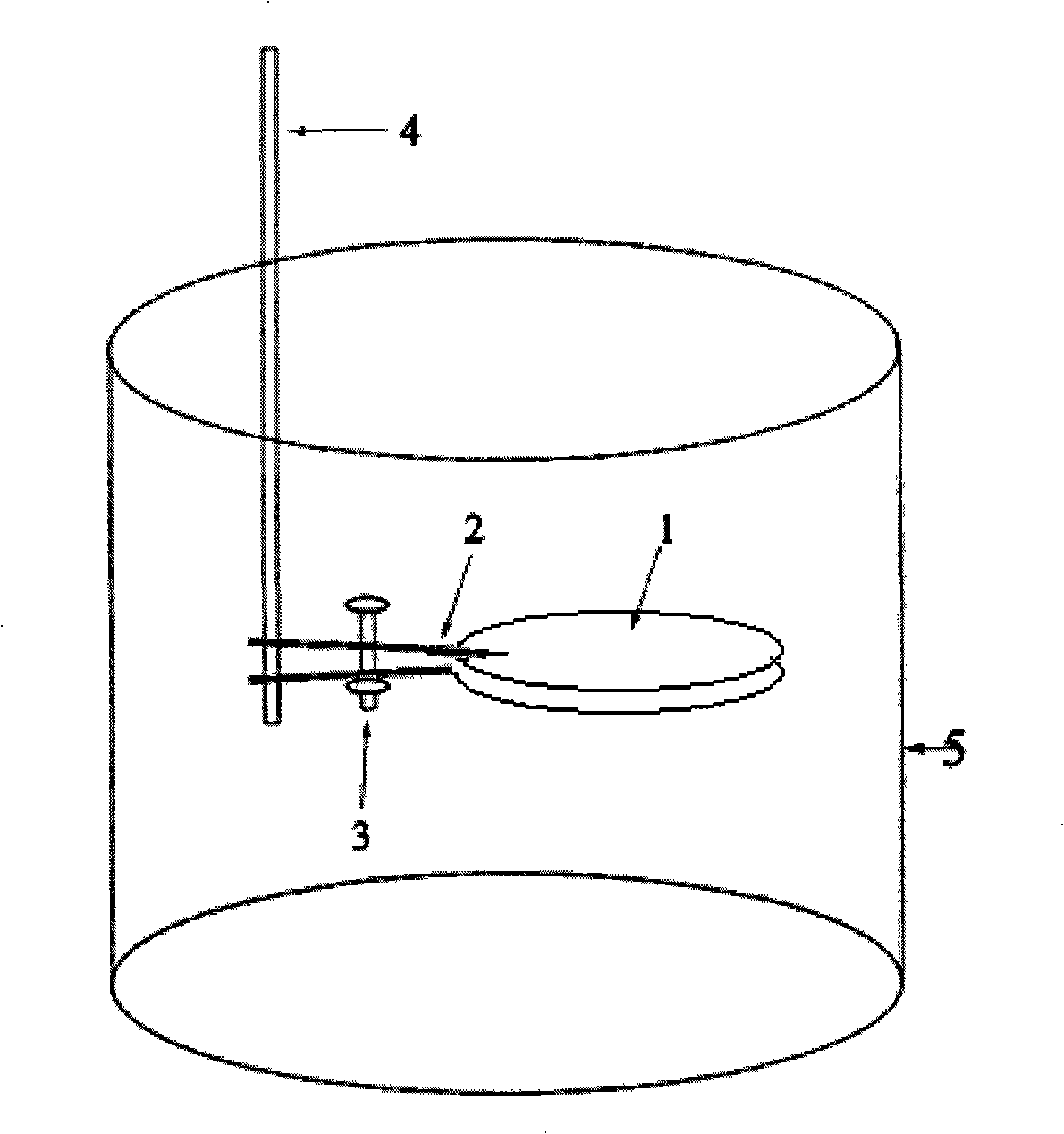

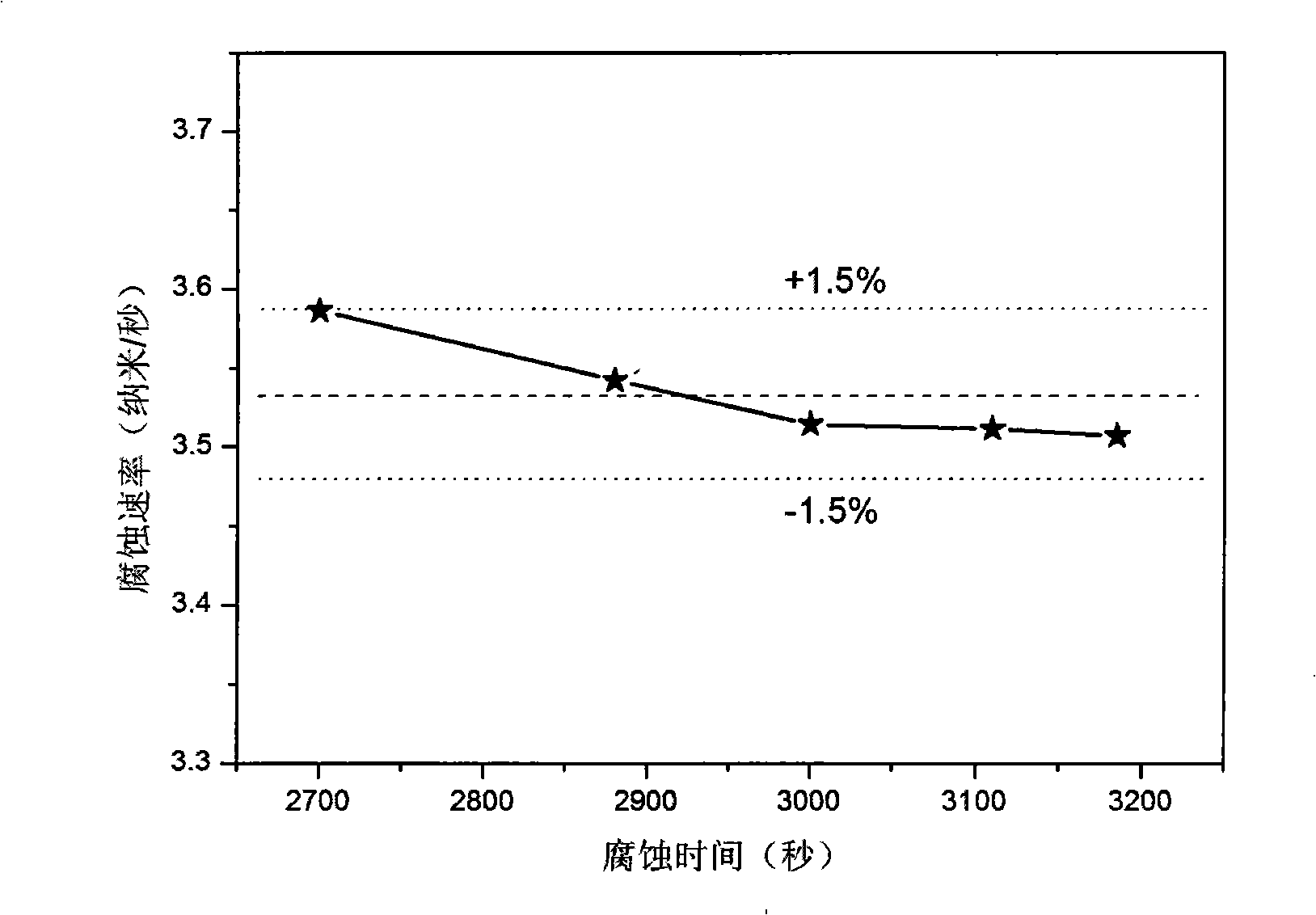

[0018] The third step: wet etching, that is, fix the device material with a fixture, put it into a beaker fille...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com