Preparation of ion liquid having B acid center and L acid center

A technology of ionic liquid and B acid, applied in the field of preparation of ionic liquid, can solve the problem of single type of acid, and achieve the effect of high thermal stability, high catalytic activity and good catalytic effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

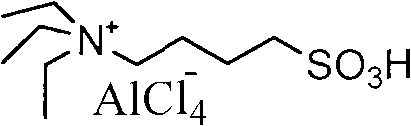

[0023] Preparation of Sulfonic Acid Functionalized Triethylamine Chloroaluminate Ionic Liquid

[0024] Preparation of step 1 ylide

[0025] Weigh the raw materials with the same amount of triethylamine and 1,4-butane sultone, stir at room temperature for 72 hours to obtain a white solid salt, then filter it with suction, and wash it three times with 99% diethyl ether, the 60 ℃ for vacuum drying, that is, the ylide.

[0026] Step 2 Hydrohalic acid acidification

[0027] Stoichiometric ylide and hydrochloric acid were weighed, the amount of hydrochloric acid was equal to the amount of sulfonate in the ylide, heated and stirred at 80° C. for 4 h, and the corresponding anion was an ionic liquid of chloride ion.

[0028] Step 3 Synthesis of Ionic Liquids

[0029] Take the above-mentioned ionic liquid and anhydrous aluminum trichloride in equal quantities, heat and stir under vacuum at 80° C. for 12 hours, and obtain the following ionic liquid having both B acid centers and L aci...

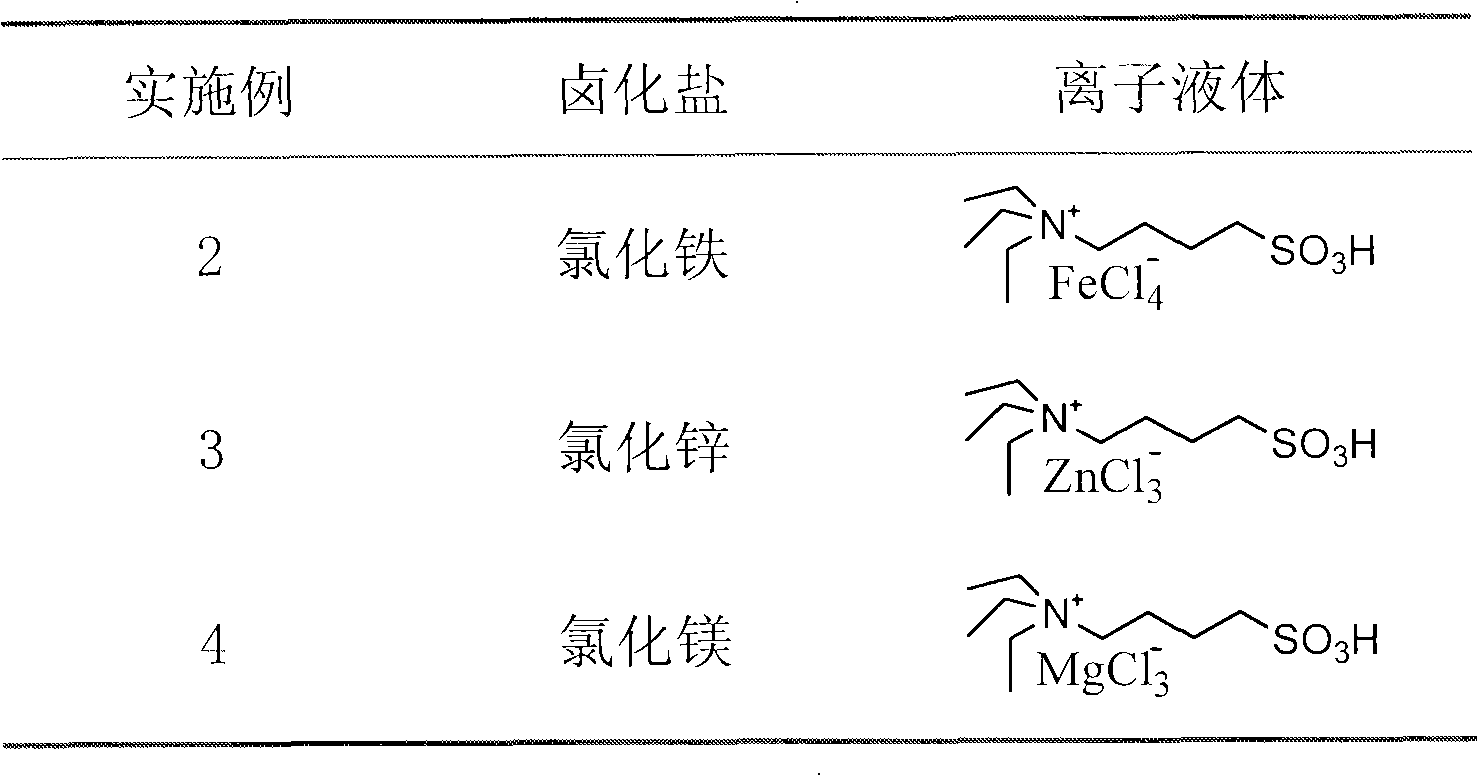

Embodiment 24

[0032] Except for the following differences, the rest are the same as in Example 1, and the metal halides in Table 1 are selected for use.

[0033] Table 1

[0034]

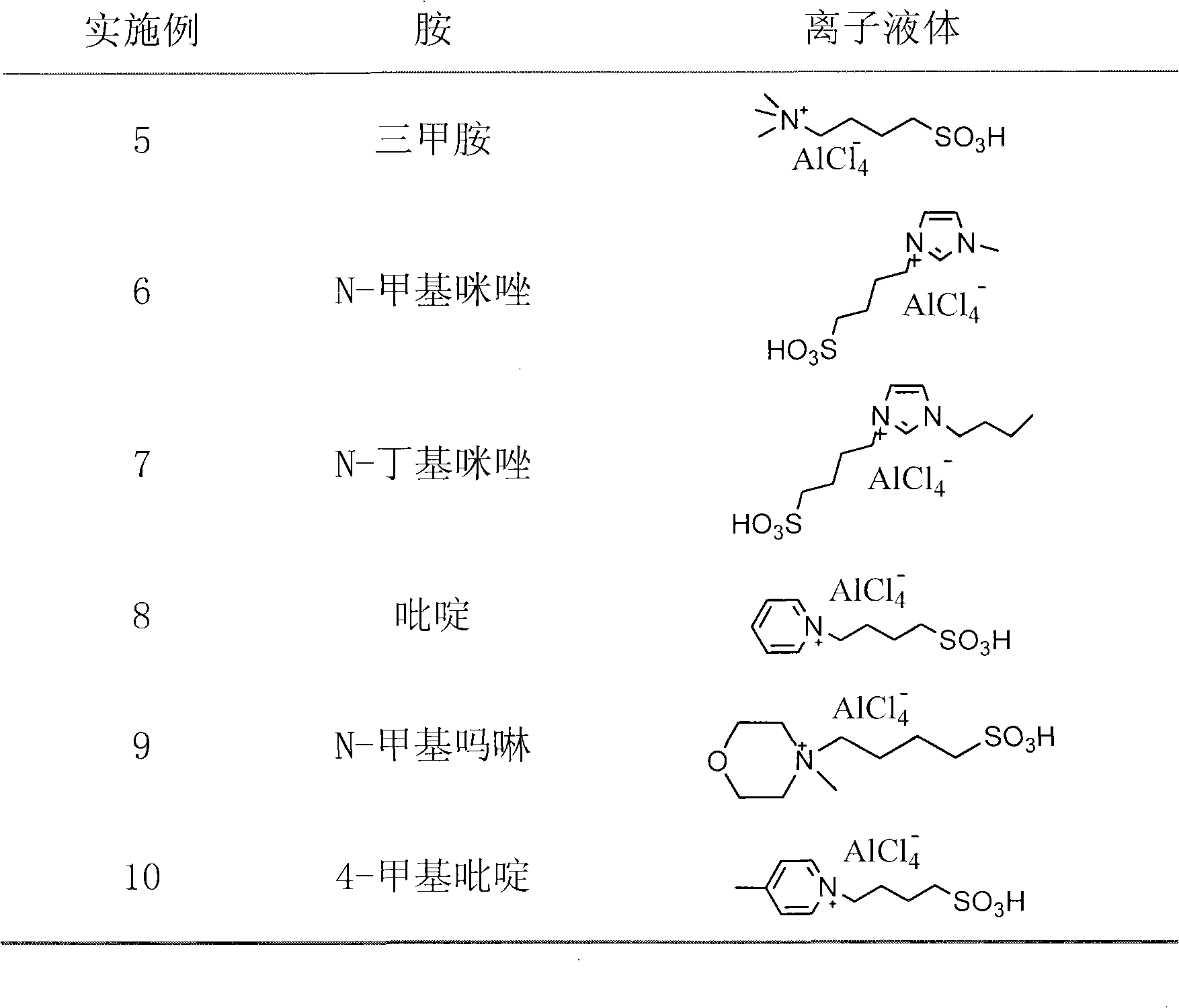

Embodiment 5-10

[0036] Except for the following differences, the rest are the same as in Example 1, and the tertiary amine compounds in Table 2 are selected.

[0037] Table 2

[0038]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com