UV curing antibiotic coating and preparation thereof

A technology of antibacterial coating and ultraviolet light, which is applied in the direction of epoxy resin coating, antifouling/underwater coating, coating, etc., can solve the problems of not having antibacterial function, etc., achieve good antibacterial effect, simple preparation process, and good antibacterial performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Synthesis of Special Functional Group Heterocyclic Compound PA

[0037] Slowly add 1.1 moles of phosphorus pentoxide into 1.5 moles of hydroxyethyl acrylate, stir while adding, control the temperature not to exceed 95°C, control the temperature at 205-110°C after the addition, add 1.1 moles of 4-hydroxy For piperidine, the temperature is controlled at 115°C and vacuumized for 2 hours, and the acid value can be detected to reach 220-260 mgKOH / g. Wherein the hydroxyethyl acrylate can also be replaced with any one of hydroxypropyl acrylate, hydroxyethyl methacrylate, and hydroxypropyl methacrylate, and the effect is the same. 4-Hydroxypiperidine can also use 2-Hydroxypiperidine to achieve the same effect.

[0038] Its physical and chemical indicators are as follows:

[0039] project

Exterior

Acid value mgKOH / g

Refractive index n D 25°C

Viscositymp.s / 25℃

index

3-4#

220-260

1.4780

1200-1500

[0040] Note: The ap...

Embodiment 2

[0043] Table 1. UV antibacterial coating benchmark formula

[0044] name

category

Dosage

Bisphenol A type epoxy acrylate EA

25-35%

Aliphatic polyurethane acrylate PUA

10-15%

Special functional group acrylate PA

5-10%

TPGDA

10-15%

10-28%

Photoinitiator 1173

5-6%

Nano acrylate

additive

3-5%

additive

0.5-1%

matte powder

Matting agent

3-6%

Wear-resistant powder

Wear-resistant material

5-10%

defoaming

0.6-2.2%

leveling agent

Leveling

0.4-1.8%

[0045] Disperse at a high speed at a speed of 900-1200r / min according to the formula amount in Table 1 and vacuumize (vacuum degree is -0.08MPa) to prepare a coating, and use curtain coating for construction, and the coating amount is 90-100g / m 2...

Embodiment 3

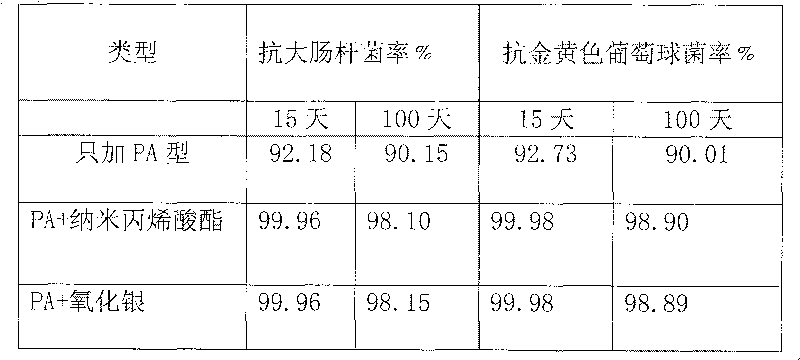

[0049] In the formula in Table 1, the special functional group acrylate PA, nano-acrylate and silver oxide were removed, and the rest remained unchanged. After the UV-cured coating was made into a film, the antibacterial performance was tested, and the nano-acrylate and silver oxide were removed, and the rest of the ingredients remained unchanged. The performance of the UV-cured coating was tested after film formation, and the results are shown in Table 3:

[0050] Table 3. Antibacterial detection without adding special antibacterial materials

[0051] category

[0052] It can be seen that the antibacterial performance is obviously improved after adding special functional group acrylate PA.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com