Civil heating stove for automatically feeding with stalk briquette as fuel

A technology of automatic feeding and heating furnace, which is applied in the directions of fuel supply, stove/stove with hot water device, application, etc., can solve the problems of not fully considering the combustion characteristics of biomass fuel, large amount of tar production, low combustion efficiency, etc. , to extend the residence time, improve the convective heat transfer coefficient, and achieve the effect of high combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

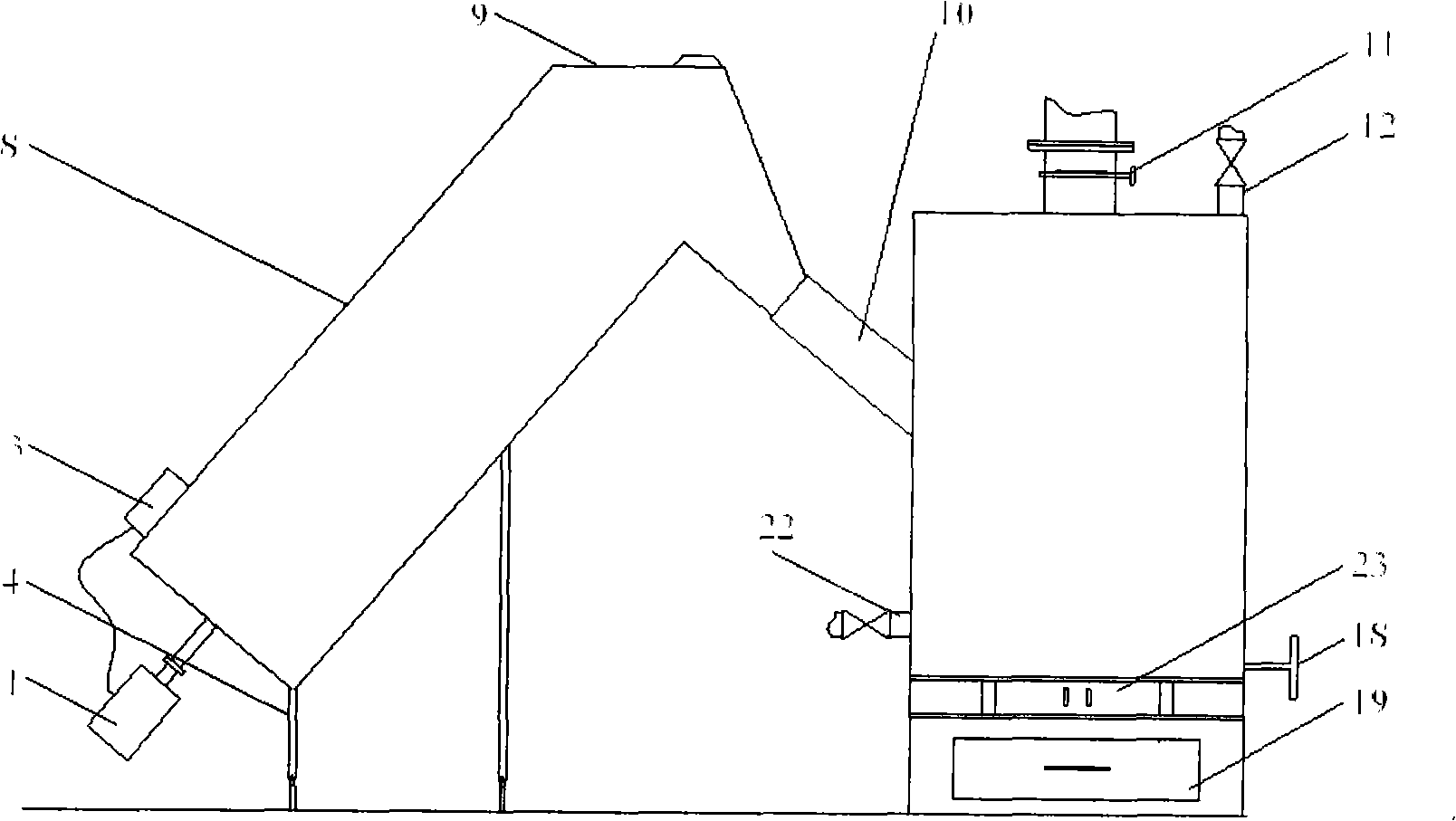

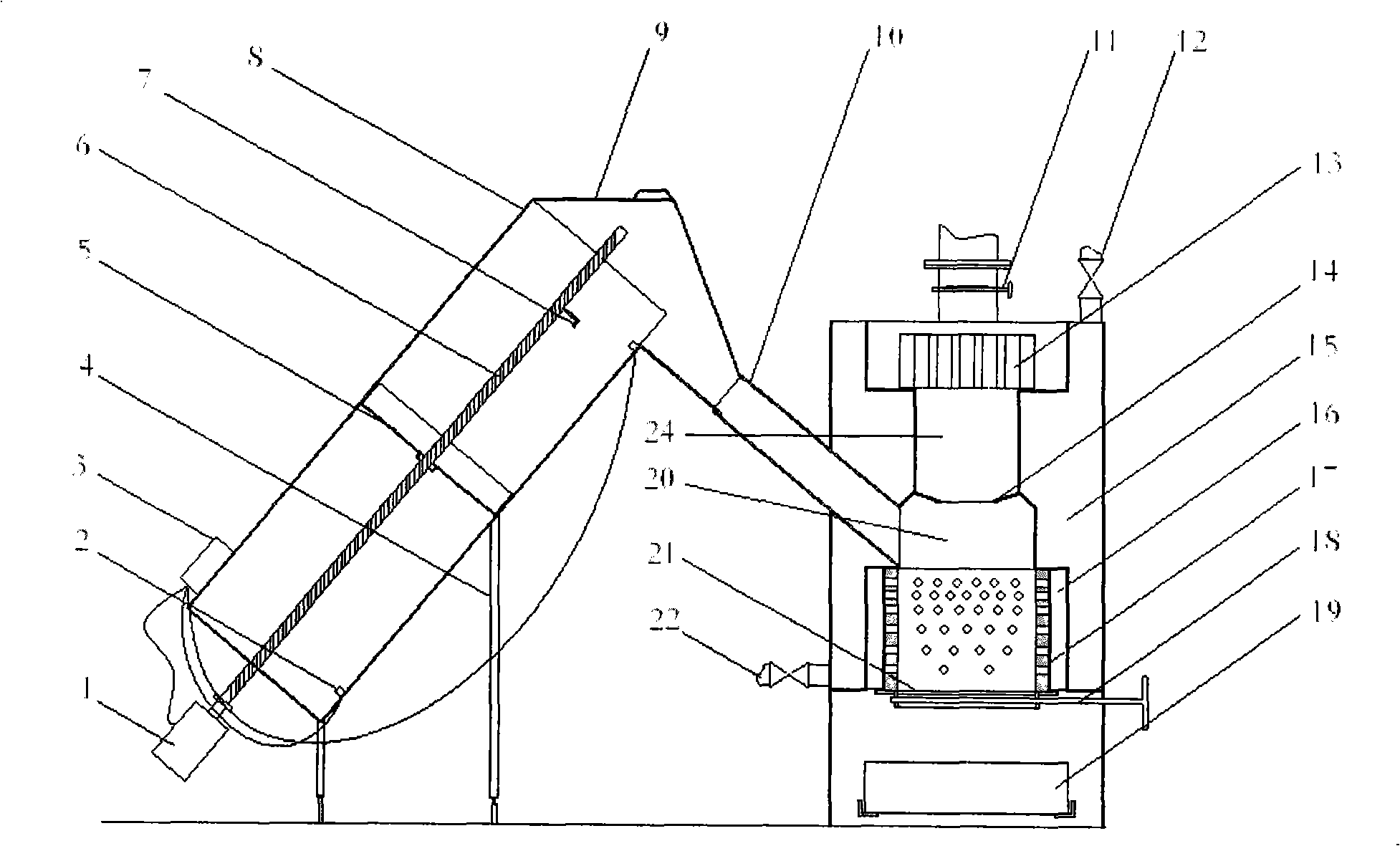

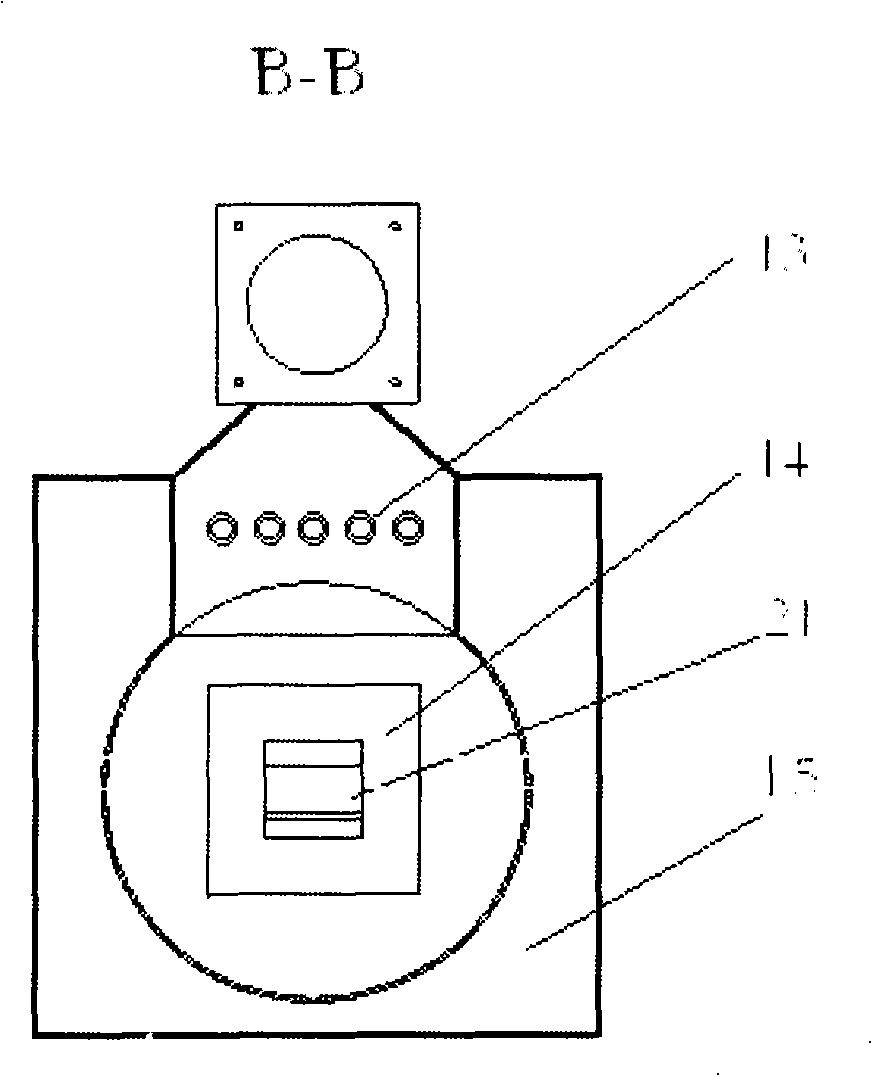

[0037] The present invention is described in detail as follows with reference to accompanying drawing:

[0038] Such as figure 1 To 4, wherein: 1. low-speed motor; 2. limit switch; 3. control box; 4. bracket; 10. Forehearth; 11. Flue baffle; 12. Hot water outlet; 13. Smokestack; 14. Bracket; 15. Water jacket; 16. Secondary air chamber; 17. Porous refractory brick; 18 , grate handle; 19, ash hopper; 20, combustion chamber; 21, shaking grate; 22, cold water inlet; 23, damper; 24, smoke chamber.

[0039] The outer shape of the heating furnace is cuboid, and the cross section is square; the furnace is composed of a combustion chamber 20 and a smoke chamber 24; The rocking fire grate 21 is positioned at the bottom of the combustion chamber 20, and is fastened on the side wall of the combustion chamber by bolts. The combustion chamber 20 is divided into upper and lower parts, wherein, the lower wall side is laid with porous refractory bricks 17, and the porous refractory bricks 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com