Method for processing anode material and battery with anode material processed by the method

A technology of positive electrode materials and processing methods, applied in battery electrodes, chemical instruments and methods, chemical/physical/physicochemical processes, etc., can solve problems affecting material performance, difficulty in preparing electrode slurry, etc., to improve cycle performance, improve Foiling ability and conductivity, effect of eliminating agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

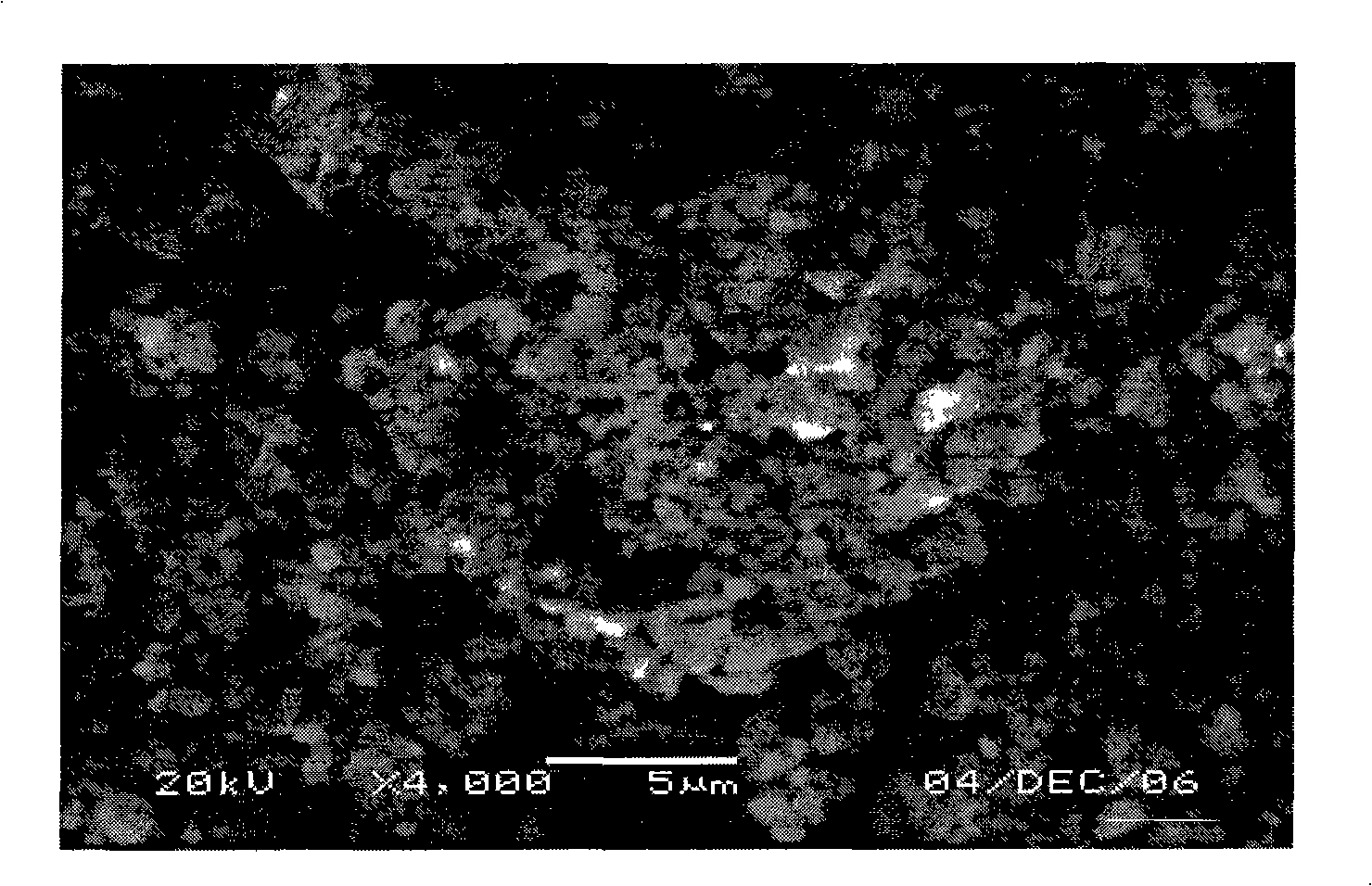

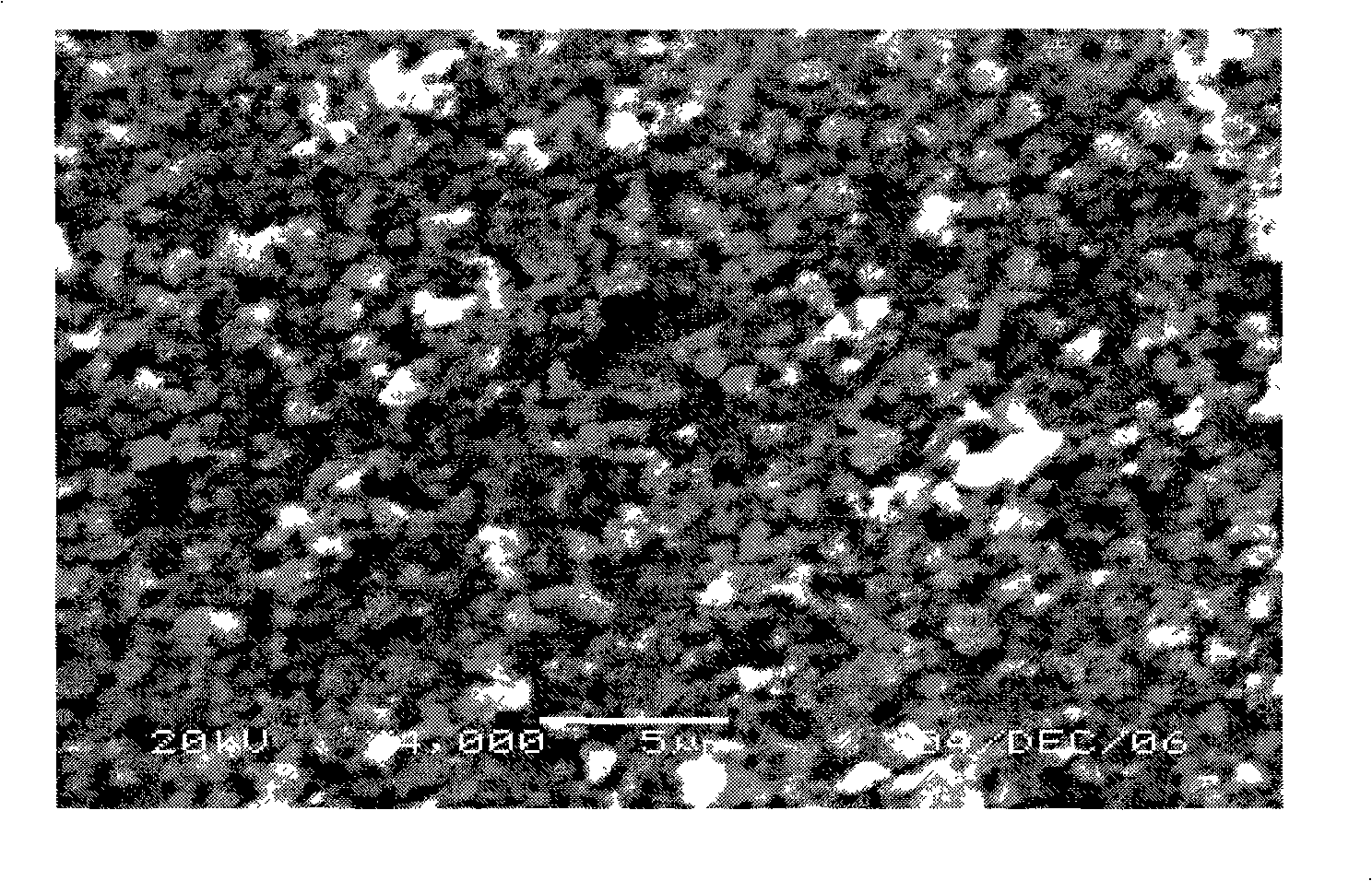

[0034] Wash the lithium iron phosphate positive electrode material with an acetone solution containing a surfactant (polyvinyl alcohol) at 20°C for 5 minutes, accompanied by stirring at 200 rpm during washing, and separate the organic residue floating on the surface after settling and carry out Solid-liquid separation, and then drying the separated positive electrode material at 80° C. for 4 hours. The SEM image of the washed lithium iron phosphate positive electrode material and the SEM image of the unwashed lithium iron phosphate are as follows figure 1 with figure 2 shown. It can be seen from the figure that the unwashed lithium iron phosphate cathode material is clustered, and after being washed with polyvinyl alcohol and acetone, the dispersion performance of the material is significantly improved.

Embodiment 2

[0036] Dissolve ethanol in deionized water, add polyvinylpyrrolidone as a surfactant, and use this solution to wash and treat lithium iron phosphate and lithium vanadium phosphate derivative positive electrode materials for 40 minutes at a temperature of 30 ° C. During washing, it is accompanied by 200 rpm. Separate the organic residue floating on the surface after settling, and carry out solid-liquid separation. The separated positive electrode material was dried at 100° C. for 16 hours.

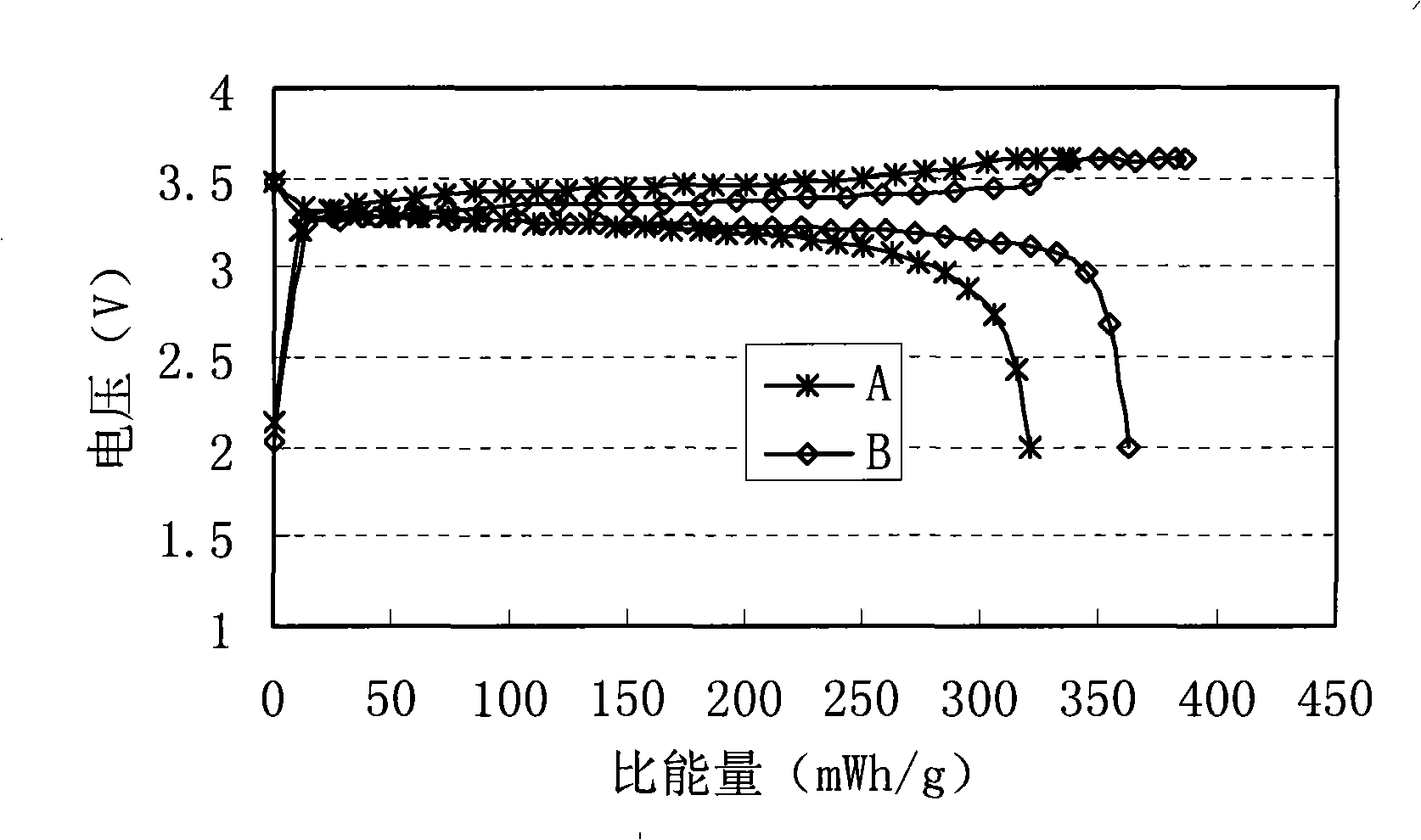

[0037] After drying, the positive electrode material derived from lithium iron phosphate and lithium vanadium phosphate is mixed with Super P, PVDF, NMP, etc. to form a positive electrode slurry with a viscosity of 4000±400mPa·s, and the density is 285g / m 2 The area density is coated, and the coated sheet is dried according to 1.80g / cm 3 The compaction density is rolled into a positive electrode sheet. Then graphite, conductive agent, CMC, SBR, industrial pure water, etc. are prepared int...

Embodiment 3

[0041] Dissolve n-propanol in industrially pure water, add sodium dodecylsulfonate as a surfactant, and use this solution to wash and treat the lithium manganate positive electrode material for 2 hours at a temperature of 65°C, with 200 rpm Separate the organic residue floating on the surface after settling, and carry out solid-liquid separation. The separated positive electrode material was dried at 120° C. for 6 hours. The dried lithium manganate cathode material is mixed with Super P, PVDF, NMP, etc. to form a cathode slurry with a viscosity of 4000mPa s, and the viscosity is 320g / m 2 The area density is coated, and the coated sheet is dried according to 1.90g / cm 3 The compaction density is rolled into a positive electrode sheet. The dry lithium manganate positive electrode material that has not been washed is replaced by the dry lithium manganate positive electrode material treated by the method of the present invention in this embodiment, and the positive electrode shee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com