Preparation method of composite bacteria fermentation bed

A technology of composite bacterial agent and fermentation bed, which is applied in the field of preparation of composite bacterial agent fermentation bed, and can solve the problems of bulky volume, environmental pollution, and low density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

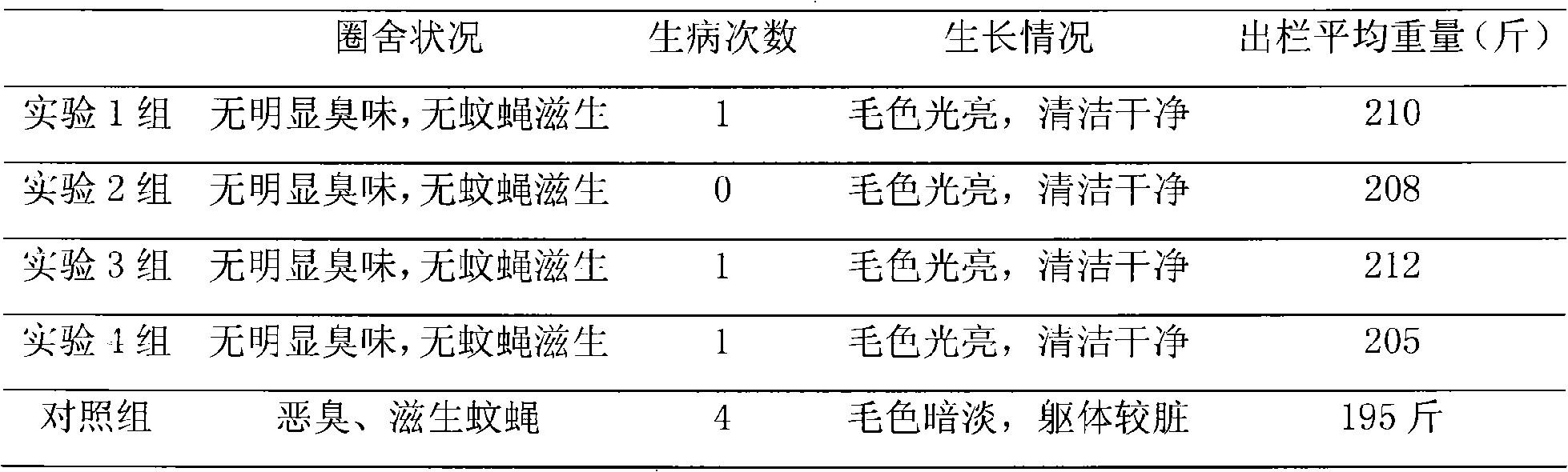

Examples

Embodiment 1

[0043] 1. Selection of fermentation strains and preparation of medium

[0044] Bacteria A——Candida tropicalis (ACCC2004), the medium is 10°Bx or 12°Bx fresh wort 1000mL, pH5.5-6.0.

[0045] Bacteria——Lactobacillus plantarum (AS1.557), the medium is glucose 20g, sodium acetate 5g, peptone 10g, sodium citrate 5g, beef extract 10g, dipotassium hydrogen phosphate 2g, yeast powder 5gMgSO 4 ·7H 2 O 0.58g, Tween-80 1ml, MnSO 4 4H 2 O0.25g, distilled water 1000ml, adjust the pH value to 6.2.

[0046] Bacteria C—Streptococcus thermophilus (IFFI06038), the medium is polypeptone 5g, plant peptone 5g, beef extract 5g, yeast extract 2.5g, disodium phosphate glycerol 19g, ascorbic acid 0.5g, MgSO 4 ·7H 2 O 0.25g, lactose 5g, pH7.1, distilled water 1000mL.

[0047] Bacteria D——Bacillus subtilis (AS 1.108), the medium is peptone 10g, beef extract 3g, NaCL 5g, distilled water 1000ml, pH7.4.

[0048] F bacterium——Bacillus subtilis (ACCC11062), the culture medium is peptone 10g, beef extr...

Embodiment 2

[0064] 1. Selection of fermentation strains and preparation of medium

[0065] Bacteria A——Candida tropicalis (ACCC2004), the medium is 10°Bx or 12°Bx fresh wort 1000mL, pH5.5-6.0.

[0066] Bacteria——Lactobacillus plantarum (AS1.557), the medium is glucose 20g, sodium acetate 5g, peptone 10g, sodium citrate 5g, beef extract 10g, dipotassium hydrogen phosphate 2g, yeast powder 5gMgSO 4 ·7H 2 O 0.58g, Tween-80 1ml, MnSO 4 4H 2 O0.25g, distilled water 1000ml, adjust the pH value to 6.2.

[0067] Bacteria C—Streptococcus thermophilus (IFFI06038), the medium is polypeptone 5g, plant peptone 5g, beef extract 5g, yeast extract 2.5g, disodium phosphate glycerol 19g, ascorbic acid 0.5g, MgSO 4 ·7H 2 O 0.25g, lactose 5g, pH7.1, distilled water 1000mL.

[0068] Bacteria D——Bacillus subtilis (AS 1.108), the medium is peptone 10g, beef extract 3g, NaCL 5g, distilled water 1000ml, pH7.4.

[0069] Bacteria E—Bacillus subtilis (ACCC11062), the culture medium is peptone 10g, beef extrac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com