Lubricating oil composition for methanol gasoline engine

A technology of lubricating oil composition and methanol gasoline, which is applied in the field of lubricating oil to achieve the effect of high alkali value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 5

[0045] The above-mentioned paraffinic base oil has a kinematic viscosity greater than 9mm at 100°C 2 / s, viscosity index greater than 90. The residual distillate oil has a kinematic viscosity greater than 30mm at 100°C 2 / s.

[0046] Its preparation method is identical with embodiment 1.

[0047] Example 6

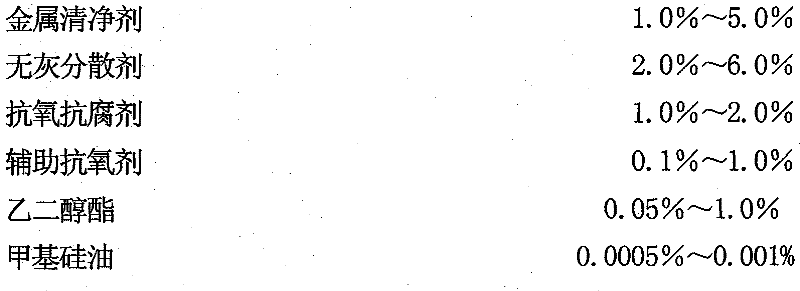

[0048] Taking the production of product 100kg of the present invention as example used raw materials and weight proportion thereof are:

[0049]

Embodiment 6

[0051] Its preparation method is identical with embodiment 1.

[0052] Example 7

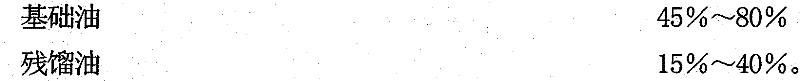

[0053] Taking the production of product 100kg of the present invention as example used raw materials and weight proportion thereof are:

[0054]

Embodiment 7

[0056] Its preparation method is identical with embodiment 1.

[0057] Example 8

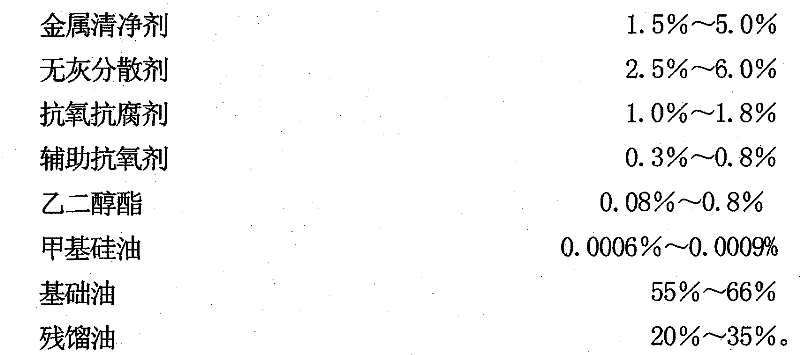

[0058] Taking the production of product 100kg of the present invention as example used raw materials and weight proportion thereof are:

[0059] The synthetic calcium sulfonate of base value 200~400 in above-mentioned embodiment 1-7 is replaced with the synthetic magnesium sulfonate of equal weight base value 200~400, monoalkenyl succinimide is replaced with the same weight of diene Replacement of alkyl succinimide, di-secondary alcohol alkyl zinc dithiophosphate with the same weight of long-chain primary alkyl zinc dithiophosphate, alkyl diphenylamine with the same weight of octyl / pentyl diphenylamine , the paraffinic base oil was replaced with a naphthenic base oil of the same weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com