Precipitation polymerization preparation method of crosslinked polystyrene microspheres

A cross-linked polystyrene and styrene technology, which is applied in the preparation of microspheres and microcapsule preparations, can solve the problems of high toxicity of acetonitrile and environmental pollution, and achieve the effects of reducing toxicity, simple and easy preparation method, and reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

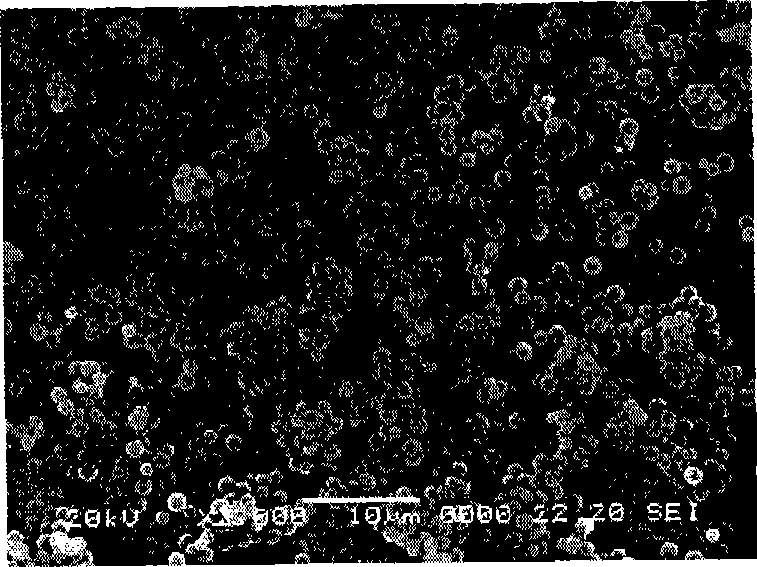

[0019] Mix 47.5 milliliters of acetonitrile, 2.5 milliliters of n-butanol, 0.35 milliliters of styrene, 0.15 milliliters of divinylbenzene and 0.0136 grams of azobisisobutyronitrile, and deoxygenate with nitrogen gas for 15 minutes, constant oscillation frequency 40 rpm, 65 Celsius reaction for 16 hours. The polymerized product was separated by centrifugation, washed with absolute ethanol, and dried to constant weight.

[0020] Gained polystyrene microsphere average particle diameter is 1.22 micron, and crosslinking degree is 24%, and monodispersity is good, and its scanning electron micrograph is as follows: figure 1 shown.

Embodiment 2

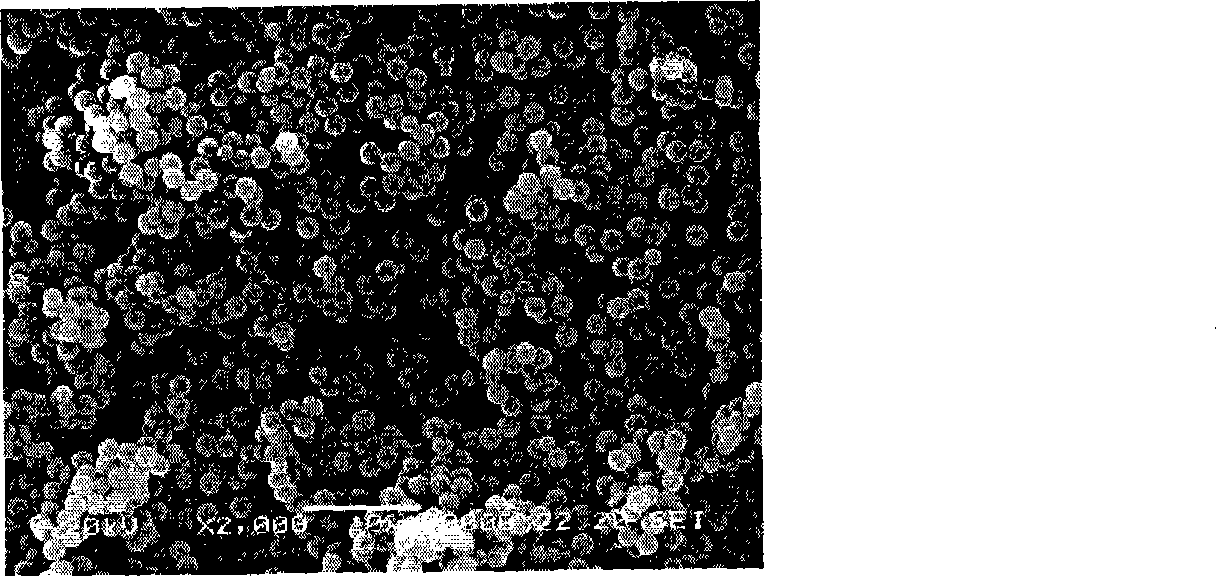

[0022] Mix 45 milliliters of acetonitrile, 5 milliliters of n-butanol, 0.25 milliliters of styrene, 0.25 milliliters of divinylbenzene and 0.0048 grams of azobisisobutyronitrile, and deoxygenate with nitrogen gas for 15 minutes, constant oscillation frequency of 70 rpm, 70 Celsius for 24 hours. The polymerized product was separated by centrifugation, washed with absolute ethanol, and dried to constant weight.

[0023] Gained polystyrene microsphere average particle diameter is 1.67 micron, and crosslinking degree is 40%, and monodispersity is good, and its scanning electron micrograph is as follows: figure 2 shown.

Embodiment 3

[0025] Mix 47.5 milliliters of acetonitrile, 2.5 milliliters of n-butanol, 1.05 milliliters of styrene, 0.45 milliliters of divinylbenzene and 0.0135 grams of azobisisobutyronitrile, and deoxygenate with nitrogen gas for 15 minutes, constant oscillation frequency of 100 rpm, 75 Celsius for 24 hours. The polymerized product was separated by centrifugation, washed with absolute ethanol, and dried to constant weight.

[0026] The obtained polystyrene microspheres have an average particle diameter of 2.20 microns, a crosslinking degree of 24%, and good monodispersity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com