Environment-friendly type baking-free building blocks and manufacturing method thereof

A technology of building blocks and manufacturing methods, applied in the field of environmental protection and building materials, can solve the problems of surface strength limitation, destruction of land resources, high production costs, etc., and achieve the effects of good product quality, environmental protection, and energy saving

Inactive Publication Date: 2009-02-11

BEIJING HENGYECUN S&T

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] There are many types of blocks for existing buildings. Traditional blocks are fired from clay. The defects of this block are that it is easy to cause damage to land resources, and the second is that it needs sintering, which wastes energy and is easy to cause pollution. environment, the third is that because the internal and external structures of this block are the same, the surface is often rough, which affects the appearance, and the surface strength is also limited, while the other block uses magnesium chloride and magnesium oxide as binders, inorganic mineral particles or Made of inorganic industrial waste as raw material, this kind of block realizes the resource utilization of solid waste to a certain extent, saves mineral resources, but the production cost is relatively high

[0003] On the other hand, in the process of building renovation and demolition of buildings, a large amount of waste mainly composed of inorganic minerals is produced. These wastes can be called construction waste. The garbage can be called mineral materials. According to the existing regulations, these garbage should be concentrated in a special treatment site for treatment. There are two common treatment methods, one is to be piled in the garbage dump; the other is to be used as a temporary construction road Cushion, finally still have to be cleared to the garbage dump, occupying a lot of space

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0031] Embodiment 1: glass fiber 5kg, fly ash 15kg, mineral material 50kg, low water cement 30kg;

Embodiment 2

[0032] Embodiment 2: glass fiber 10kg, fly ash 12kg, mineral material 40kg, low water cement 40kg, iron ore tailings 20kg;

Embodiment 3

[0033] Example 3: 7kg of glass fiber, 10kg of fly ash, 30kg of mineral materials, 50kg of low-water cement, 15kg of fly ash, and 30kg of iron ore tailings.

[0034] The preparation method is as described above.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

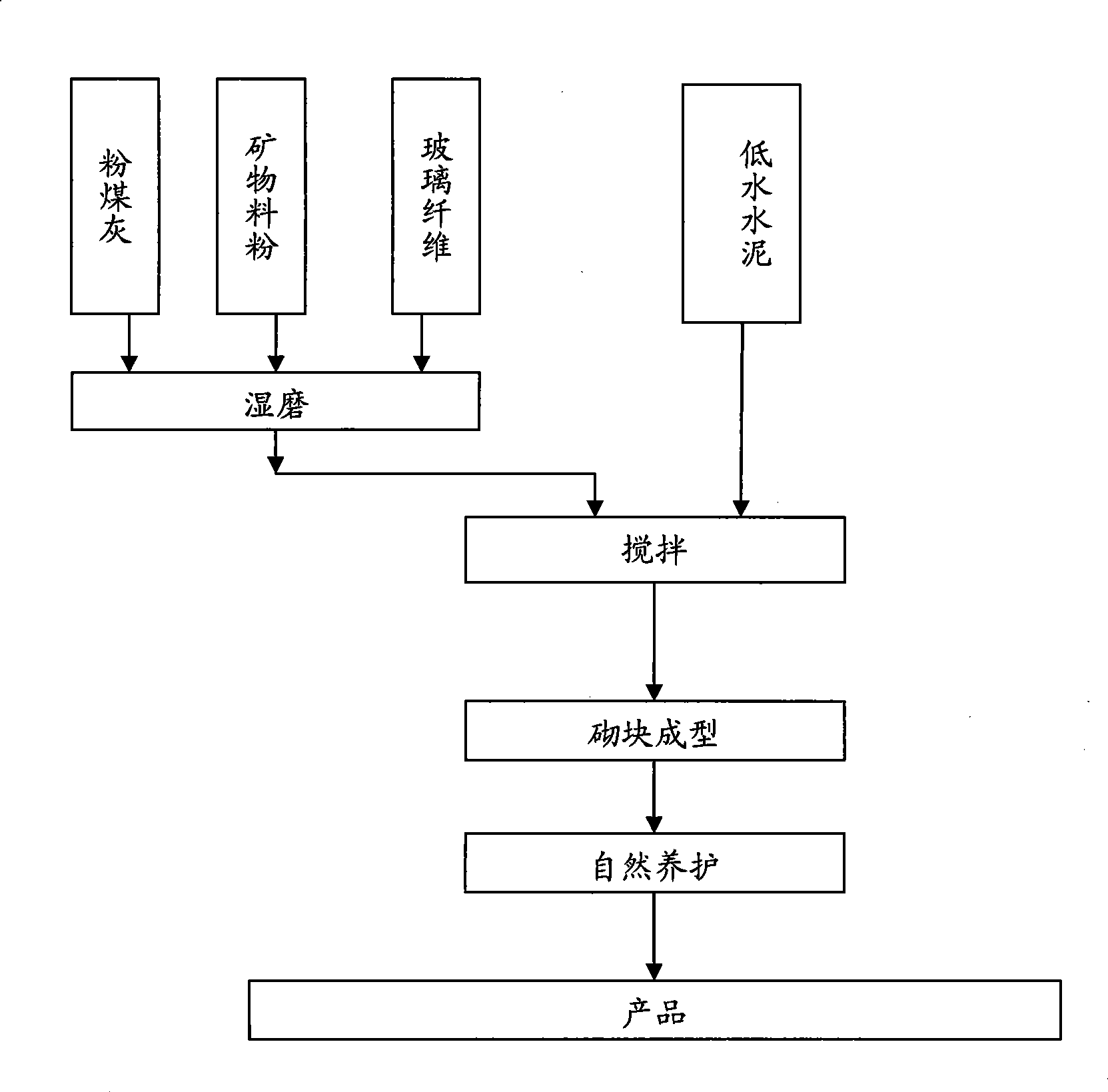

The invention relates to an environmentally-friendly unburned building block and a manufacturing method thereof, raw materials thereof mainly comprise inorganic non-metallic granular materials, fly ash, low-water cement and glass fibers, wherein, the glass fibers account for 5 to 10 parts, the fly ash accounts for 10 to 15 parts, the mineral materials account for 30 to 50 parts, the low-water cement accounts for 30 to 50 parts, and the particle size of various materials shall be 40 meshes or even finer. The inorganic non-metallic granular materials are sorted out from building garbage, the various materials are prepared according to the proportion, large pieces of large granular materials are ground into the required fineness, the ground materials and other powder materials are mixed and stirred by adding water to form material slurry, and a product can be formed by natural conservation after the forming. The environmentally-friendly unburned building block greatly utilizes the inorganic non-metallic granular materials, the fly ash and other solid wastes which are difficult to be utilized in the building garbage as raw materials, thereby realizing the recycling of material resources; at the same time, the production cost is lower.

Description

technical field [0001] The invention relates to an environment-friendly burning-free building block and a manufacturing method thereof, which belong to the technical field of environmental protection and building materials. Background technique [0002] There are many types of blocks for existing buildings. Traditional blocks are fired from clay. The defects of this block are that it is easy to cause damage to land resources, and the second is that it needs sintering, which wastes energy and is easy to cause pollution. environment, the third is that because the internal and external structures of this block are the same, the surface is often rough, which affects the appearance, and the surface strength is also limited, while the other block uses magnesium chloride and magnesium oxide as binders, inorganic mineral particles or Made of inorganic industrial waste residues as raw materials, this block realizes the resource utilization of solid waste to a certain extent and saves...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C04B28/00C04B18/08C04B14/42

CPCC04B28/02C04B18/167C04B2111/00017Y02W30/91C04B20/02C04B14/42C04B18/02C04B18/08

Inventor 王丽

Owner BEIJING HENGYECUN S&T

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com