Macroporous reticular polyvinyl alcohol foam and preparation thereof

A polyvinyl alcohol and polyvinyl alcohol gel technology, which is applied in the field of bioengineering, can solve the problems of poor impact resistance of polymer materials, short service life of immobilized microorganisms, unfavorable mass transfer of microorganisms, etc., and achieves good water resistance, Toxic elimination, obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

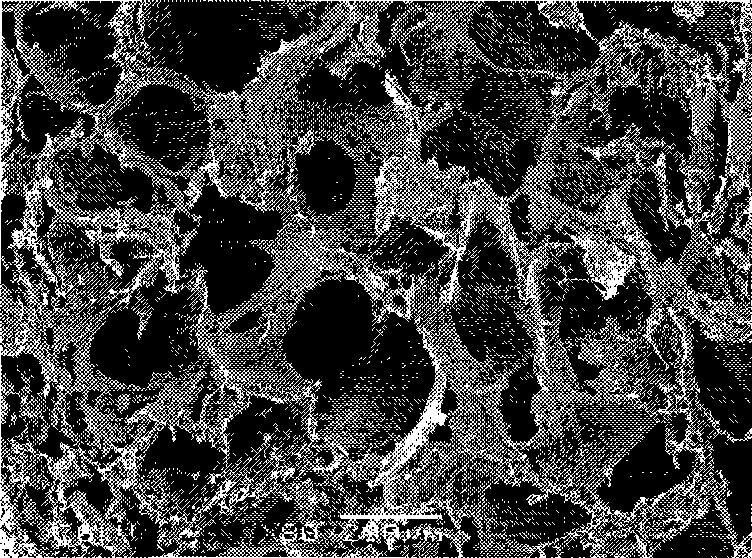

[0033] Put PVA, limestone and water in a three-necked flask at a mass ratio of 18:10:100 for mixing, heat, stir, and fully dissolve the mixture in a boiling water bath. Stop heating after the PVA is completely dissolved and the system is evenly mixed, and cool to room temperature under stirring. At this time, the system is in the form of white sol with relatively high viscosity.

[0034] The above sol was added with 34ml of hydrochloric acid solution with a mass concentration of 15% under vigorous stirring, the mixture began to foam, and when the volume expanded to 3 times the original volume, it began to freeze. The freezing method is: freeze at -20°C for 12 hours, then thaw naturally at room temperature for 3 hours, and cycle freezing and thawing three times in this way to generate a large-pore mesh PVA gel foam; cut the gel foam into 2×2×2cm Small pieces, continue to soak in hydrochloric acid with a mass concentration of 1% until no bubbles are formed.

[0035] Put the cl...

Embodiment 2

[0037] Put PVA, limestone and water in a three-necked flask at a mass ratio of 18:10:100 for mixing, heat, stir, and fully dissolve the mixture in a boiling water bath. Stop heating after the PVA is completely dissolved and the system is evenly mixed, and cool to room temperature under stirring. At this time, the system is in the form of white sol with relatively high viscosity.

[0038] The above sol was added with 34ml of hydrochloric acid solution with a mass concentration of 15% under vigorous stirring, the mixture began to foam, and when the volume expanded to 3 times the original volume, it began to freeze. The freezing method is: freeze at -20°C for 12 hours, then thaw naturally at room temperature for 3 hours, and cycle freezing and thawing three times in this way to generate a large-pore mesh PVA gel foam; cut the gel foam into 2×2×2cm Small pieces, continue to soak in hydrochloric acid with a mass concentration of 1% until no bubbles are formed.

[0039] Soak the g...

Embodiment 3

[0041] Put PVA, limestone and water in a three-necked flask at a mass ratio of 18:10:100 for mixing, heat, stir, and fully dissolve the mixture in a boiling water bath. Stop heating after the PVA is completely dissolved and the system is evenly mixed, and cool to room temperature under stirring. At this time, the system is in the form of white sol with relatively high viscosity.

[0042] The above sol was added with 34ml of hydrochloric acid solution with a mass concentration of 15% under vigorous stirring, the mixture began to foam, and when the volume expanded to 3 times the original volume, it began to freeze. The freezing method is: freeze at -20°C for 12 hours, then thaw naturally at room temperature for 3 hours, and cycle freezing and thawing three times in this way to generate a large-pore mesh PVA gel foam; cut the gel foam into 2×2×2cm Small pieces, continue to soak in hydrochloric acid with a mass concentration of 1% until no bubbles are formed.

[0043] The gel fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com