Extraction method of alfalfa leaf protein

A technology of alfalfa leaf protein and extraction method, which is applied to the preparation method of peptides, chemical instruments and methods, and methods based on microorganisms. It can solve the problems of high energy consumption, large solvent consumption, and energy consumption in heating methods, and achieve energy efficiency. Low consumption, simple process, and the effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

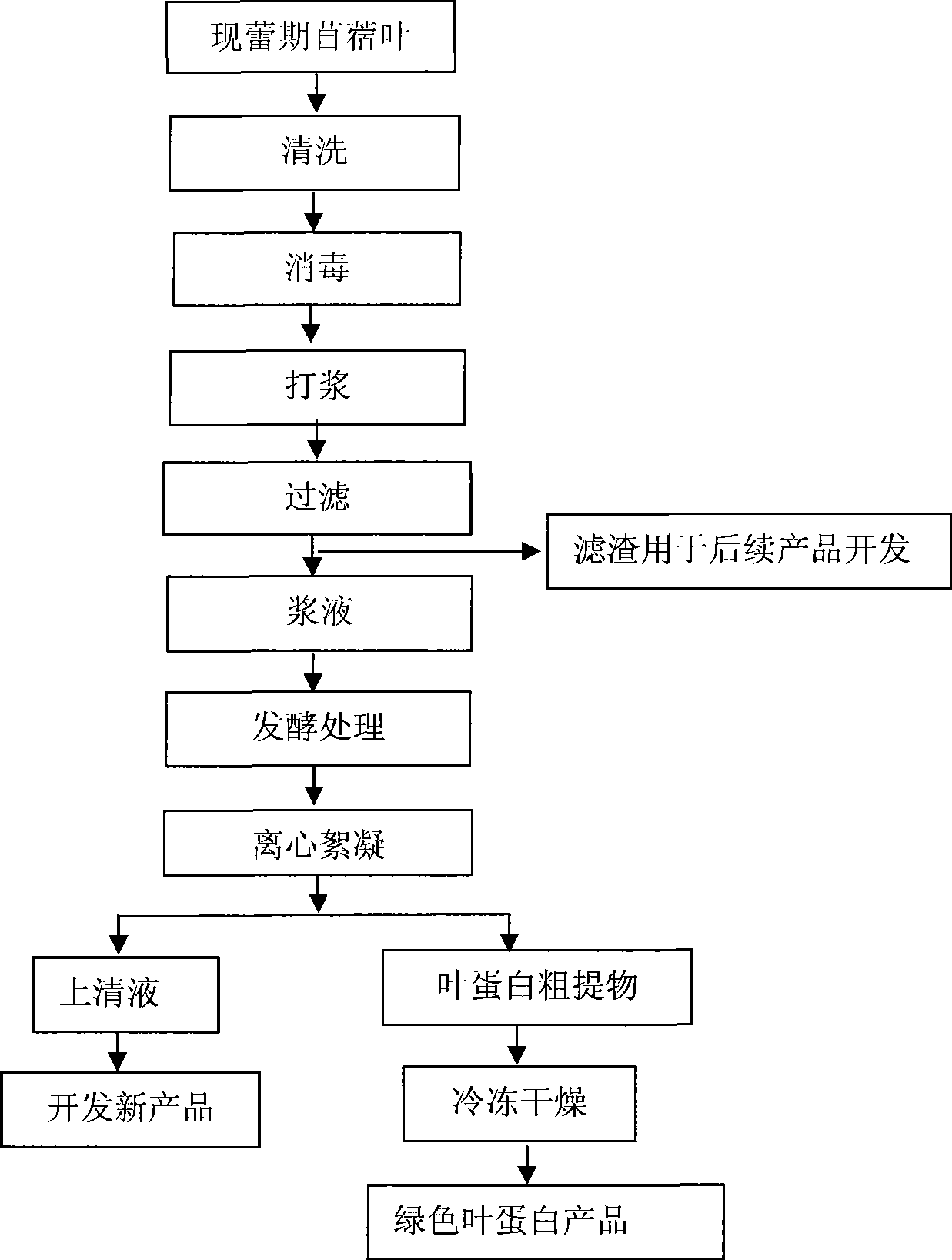

[0031] This embodiment provides a method for extracting alfalfa leaf protein, mainly extracting leaf protein from alfalfa leaf pulp by fermentation, such as figure 1 As shown, the method specifically includes:

[0032] The raw material is the alfalfa leaves of alfalfa in the budding stage. Generally, the budding stage refers to the fresh alfalfa in the second budding stage, or the fresh alfalfa in the third budding stage, or the fresh alfalfa in the second budding stage and the first crop. For fresh alfalfa in the budding period of three batches, the raw material of the alfalfa leaf is cleaned with tap water, and the withered, yellowed, rotten and pest-infested leaves in the raw material of the alfalfa leaf are removed by cleaning, and the soil, dust and some parasites on the surface of the alfalfa leaf are cleaned. After cleaning, the alfalfa leaves are beaten. Generally, the alfalfa leaves and water accounting for 90% to 95% of the weight of the alfalfa leaves are put into a...

Embodiment 2

[0037] The present embodiment provides a kind of alfalfa leaf protein extraction method, the alfalfa that selects is the fresh alfalfa of the 2nd stalk budding period and the 3rd vegetative period fresh alfalfa, obtain 2382.5 kilograms of alfalfa fresh grass after harvesting, wherein blade and young stem and leaf, 1,186.75 kg of flowers and 1,195.75 kg of stems; harvest about 655 kg of fresh alfalfa in the second budding stage, about 986.5 kg of fresh alfalfa in the second budding stage, and harvest fresh alfalfa in the third vegetative growth period Grass about 741 kg;

[0038] In order to avoid pollution, the alfalfa leaves separated from the stalks need to be cleaned to remove the withered, yellowed, rotten and pest-infested leaves, the soil, dust and some parasitic bacteria on the surface of the leaves are cleaned, and non-polluting disinfection measures are taken , to further kill microorganisms; beat the cleaned and sterilized alfalfa leaves using HR2839 / AC Phillips beat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com