Nontoxic process for extraction gold from gold-bearing tailing

A technology of tailings and mineral processing agents, applied in the field of mineral processing, can solve the problems of high cost and small processing capacity, and achieve the effect of high recovery efficiency and low recovery cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

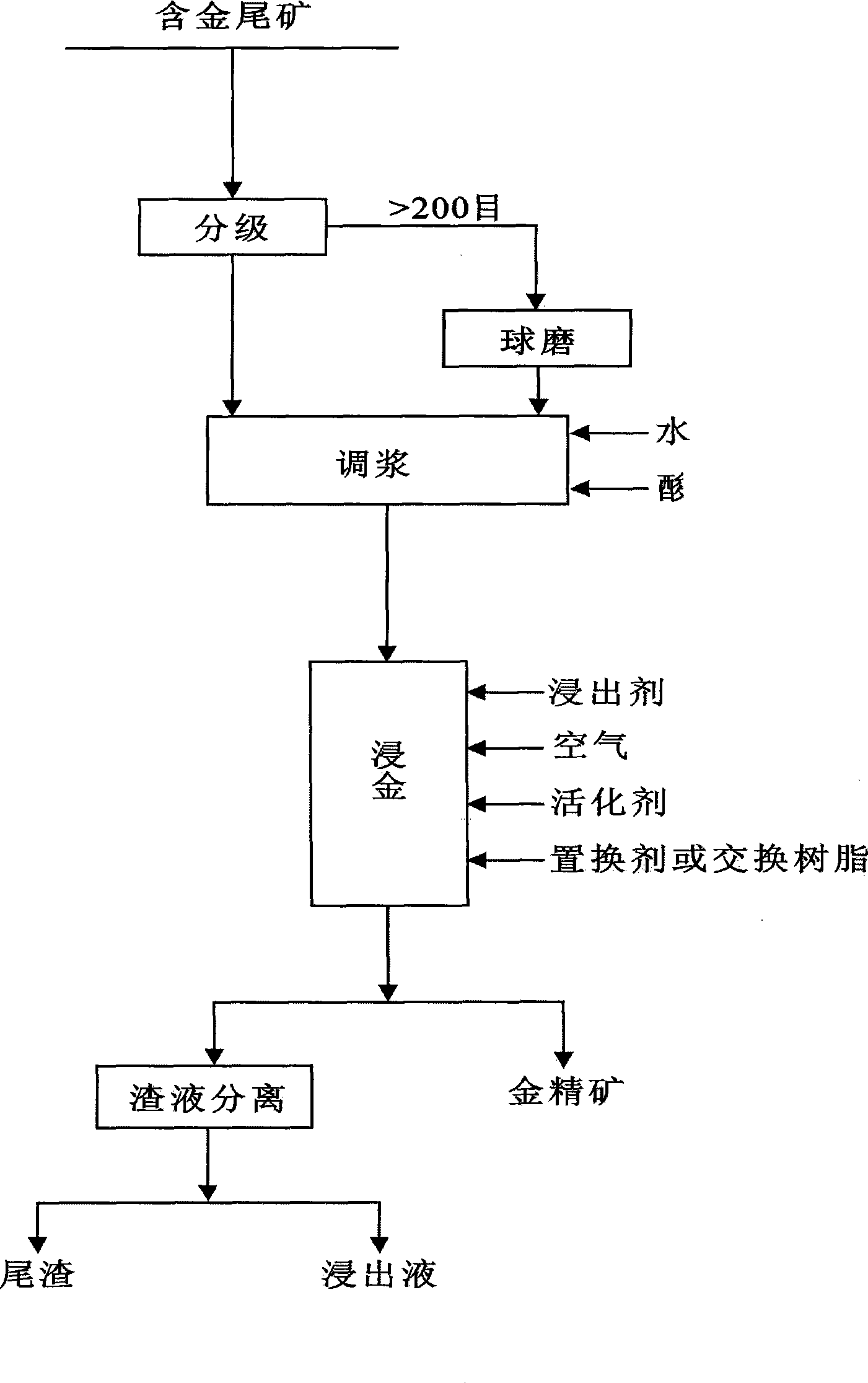

Method used

Image

Examples

Embodiment 1

[0026] Take 1000 grams of high-bismuth-type gold-bearing tailings in Shandong, first classify, sieve out particles > 200 mesh, ball mill to ≤ 200 mesh, put them in the slurry mixing tank, add water at a ratio of 1 / 2.5 of mineral water, and adjust the slurry to the concentration is 40%, add concentration by weight percentage and be 2.0g of sulfuric acid of 95%, stir ten minutes, place the ore slurry after lowering down in the gold immersion tank, add thiourea 1.5g by weight percentage, simultaneously with 6 liters per hour Inject air into the gold immersion tank at a high speed, then add 2.5g of ferric chloride, and then press 6m 2 / m 3 The measurement put the zinc-iron plate in the gold leaching tank and leached for 43 hours. The gold was replaced with the zinc-iron plate. The gold extraction rate was 89.8%.

Embodiment 2

[0028] Take 1000 grams of gold-containing tailings from a gold mine in Shandong, first classify, screen out >200 mesh particles, ball mill to ≤200 mesh, put them in the slurry mixing tank, add water at a ratio of 1 / 2.5 of the mineral water, and adjust the slurry to a concentration of 40%, adding 1.4g of sulfuric acid with a concentration of 98% by weight percentage, stirring for 8 minutes, placing the lowered ore slurry in a gold leaching tank, adding thiourea 3.6g by weight percentage, and simultaneously at a speed of 6 liters per hour Air is introduced into the gold leaching tank, and then 6.0 g of 732 cation exchange resins are added, the gold is adsorbed by the 732 cation exchange resins, and the extraction rate of gold is 90.8%. After pressure filtration, the tailings are discarded, and the leaching liquid is recovered and reused.

Embodiment 3

[0030] Take 1000 grams of gold-containing tailings from a gold mine in Jilin, first classify, screen out >200 mesh particles, ball mill to ≤200 mesh, put them in the slurry mixing tank, add water at a ratio of 1 / 2.5 of the mineral water, and adjust the slurry to a concentration of 40%, adding concentration by weight percentage is the sulfuric acid 3g of 96%, stirs 5 minutes, the ore slurry after lowering is placed in gold immersion tank, adds thiourea 3.5g by weight percentage, simultaneously with the speed of 6 liters per hour to Put air into the gold leaching tank, then add 5.0g of anhydrous ferric sulfite, and then press 12m 2 / m 3 The metering of the zinc iron plate is placed in a gold immersion tank, adjusted by adding 200g / t of sodium hydroxide, and leached for 40 hours. The gold is replaced with the zinc and iron plates, and the gold extraction rate is 91.6%. After pressure filtration, the tailings are discarded, and the ore leaching liquid is recovered and reused.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com