Double braid nerve trachea and preparation method thereof

A technology of nerve conduit and double-layer braiding, which is applied in the field of biomedical materials and tissue engineering, can solve the problems of brittle collapse, high brittleness, increased nerve conduit, bridge defect distance, nerve regeneration, etc., and achieve good cell compatibility , good mechanical properties, the effect of increasing the distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A double-layer braided nerve conduit is composed of an outer wall made of polyglycolide-lactide yarn and an inner wall made of chitin non-woven fabric.

[0024] The above-mentioned double-layer braided nerve guide is prepared by the following method: attaching chitin non-woven fabric to a mandrel to form an inner tube wall, and weaving polyglycolide-lactide yarns on its outer layer to form an outer tube wall; Set it at 90°C for 2 minutes, wash it with absolute ethanol, and set it at 90°C for 1 minute; remove the outer tube wall made of polyglycolide-lactide and the inner tube wall made of chitin non-woven fabric from the mandrel At the same time, it was withdrawn and freeze-dried at -50°C for 2 hours.

Embodiment 2

[0026] A double-layer braided nerve conduit is composed of an outer wall made of polyglycolide-lactide yarn and an inner wall made of chitin non-woven fabric.

[0027]The above-mentioned double-layer braided nerve guide is prepared by the following method: attaching chitin non-woven fabric to a mandrel to form an inner tube wall, and weaving polyglycolide-lactide yarns on its outer layer to form an outer tube wall; Set it at 105°C for 5 minutes, wash it with absolute ethanol, and set it at 100°C for 2 minutes; remove the outer wall made of polyglycolide-lactide and the inner wall made of chitin non-woven fabric from the mandrel At the same time, it was withdrawn and freeze-dried at -40°C for 3 hours.

Embodiment 3

[0029] A double-layer braided nerve conduit is composed of an outer wall made of polyglycolide-lactide yarn and an inner wall made of chitin non-woven fabric.

[0030] The above-mentioned double-layer braided nerve guide is prepared by the following method: attaching chitin non-woven fabric to a mandrel to form an inner tube wall, and weaving polyglycolide-lactide yarns on its outer layer to form an outer tube wall; Set it at 100°C for 3.5 minutes, wash it with absolute ethanol, and set it at 95°C for 1.5 minutes; the outer wall made of polyglycolide-lactide and the inner wall made of chitin non-woven fabric are removed from the core The sticks were withdrawn at the same time, and freeze-dried at -45°C for 2.5 hours.

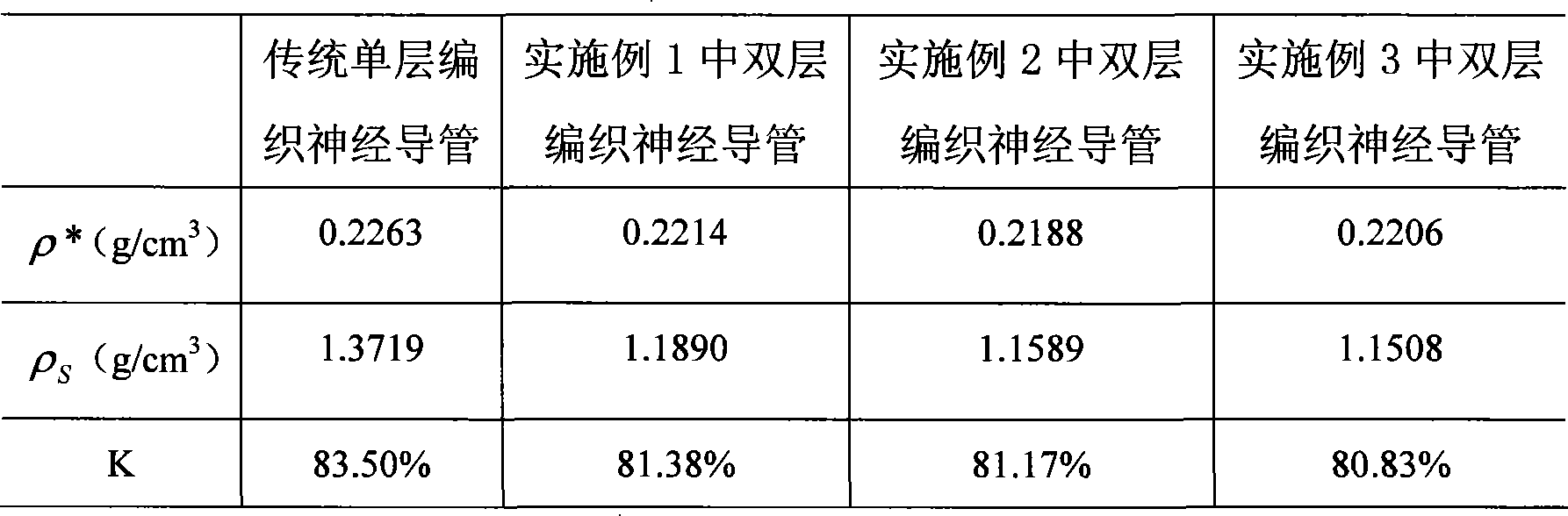

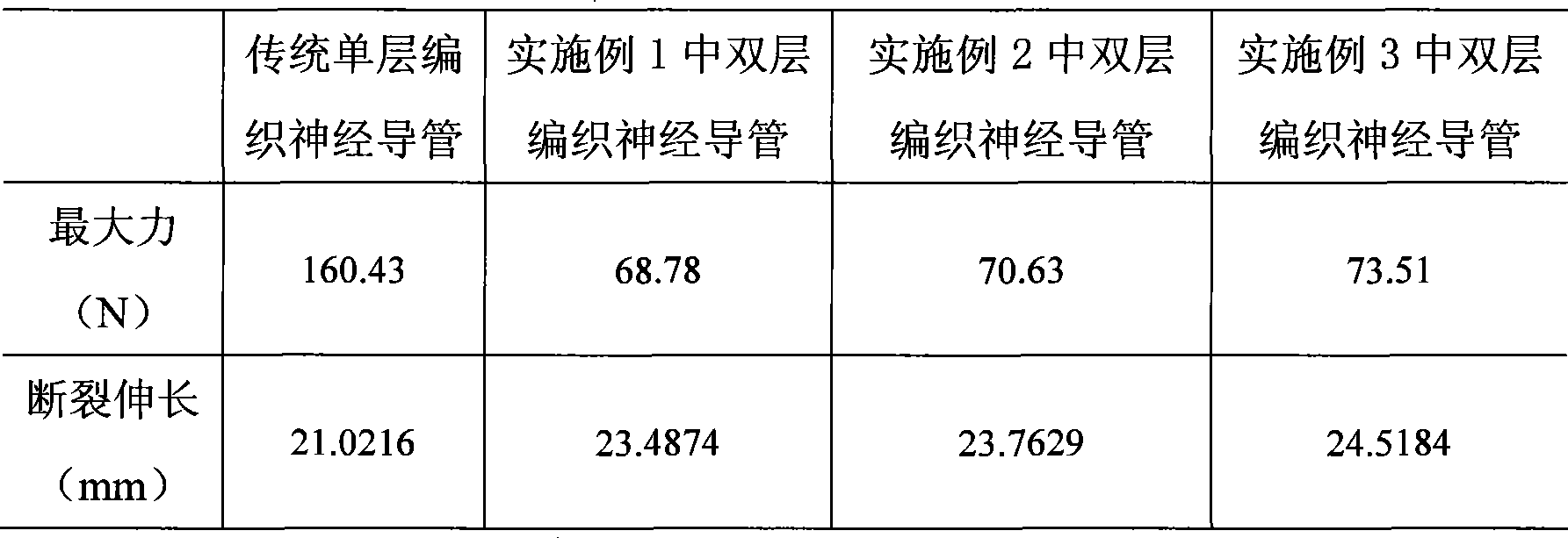

[0031] The performance test of the double-layer braided nerve guide of embodiment 1-3 is as follows:

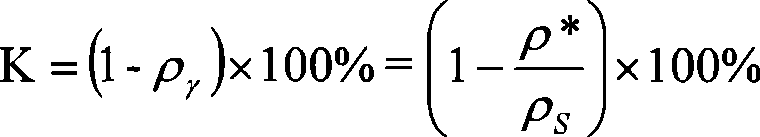

[0032] 1. Measurement and comparison of porosity: The concept equivalent to porosity is "relative density", which is the ratio of the apparent density of a po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com