Preparation method for titanium dioxide doping photocatalyst

A photocatalyst, titanium dioxide technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the high recombination rate of photogenerated carriers, restricting the application of titanium dioxide, Solve the problems of low utilization rate of sunlight and achieve the effect of not harsh process conditions, low equipment requirements and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] a. Mix 30ml of tetra-n-butyl titanate and 20ml of absolute ethanol at room temperature, and stir for 40min to obtain a uniform and transparent yellow solution 1.

[0019] b. At room temperature, 0.2983g Ni(CH 3 COO) 2 .4H 2 O was dissolved in 10ml of absolute ethanol to form a green solution 2, which was added to solution 1 and stirred for 2h.

[0020] c. Slowly drop the acetic acid solution with pH=3 into the above mixed solution under stirring until a gel is formed.

[0021] d. The gel is dried in an oven at 80° C. to obtain a dry gel, which is ground into a powder.

[0022] e. Mix 0.8007 g of the above powder with 0.6002 g of urea, and calcinate at 400° C. for 6 hours to obtain a nitrogen-nickel co-doped titanium dioxide photocatalyst.

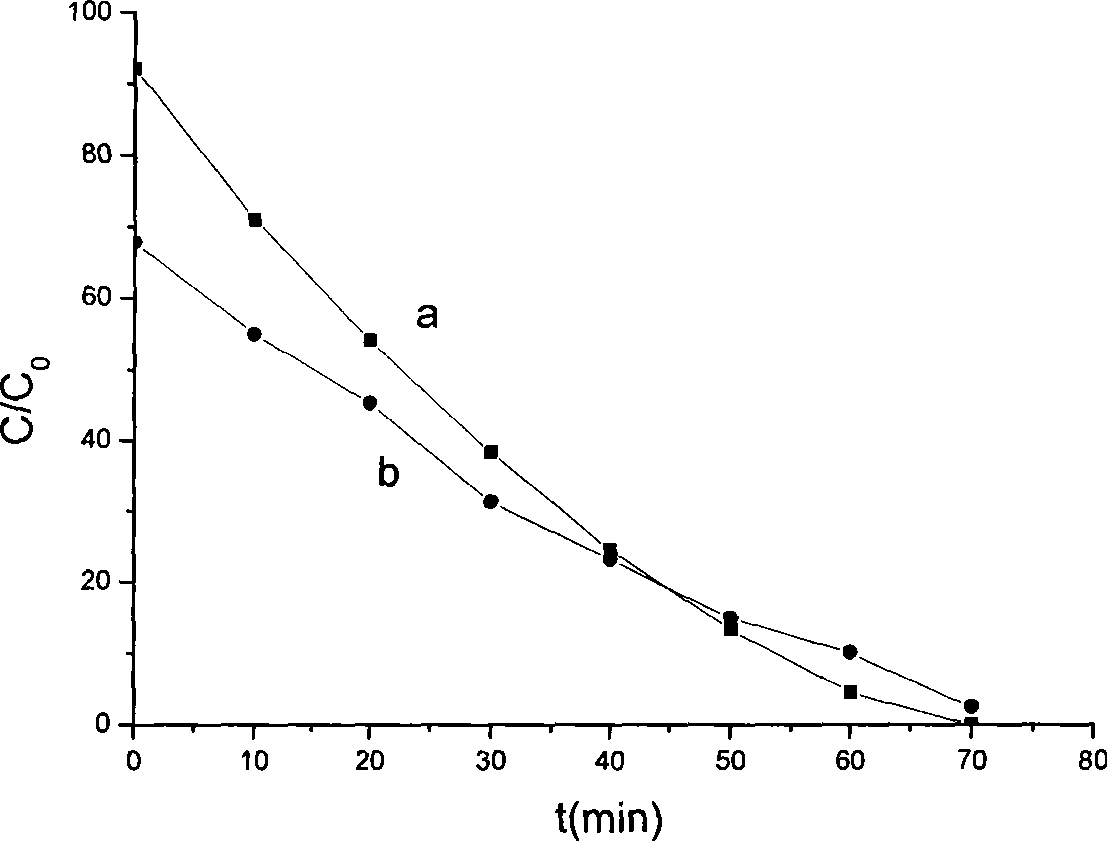

[0023] f, get above-mentioned photocatalyst 0.1130g, 113ml of isatin solution of 10mg / L joins in reaction container, dark reaction 1h, light source is the tungsten halogen lamp (simulation sunlight) of 500W, after illumination 70...

Embodiment 2

[0025] a. Mix 30ml of tetra-n-butyl titanate and 20ml of absolute ethanol at room temperature, and stir for 20min to obtain a uniform and transparent yellow solution 1.

[0026] b. Add 0.2563g Ni(NO 3 ) 2 .6H 2 O was dissolved in 10ml of absolute ethanol to form a green solution 2, which was added to solution 1 and stirred for 1h.

[0027] c. Slowly drop the nitric acid solution with pH=2 into the above mixed solution under stirring until a gel is formed.

[0028] d. The gel is dried in an oven at 60° C. to obtain a dry gel, which is ground into powder.

[0029] e. Mix 0.8004 g of the above powder with 1.8006 g of urea, and calcinate at 500° C. for 2 hours to obtain a nitrogen-nickel co-doped titanium dioxide photocatalyst.

[0030] f. Take 0.1040 g of the above-mentioned photocatalyst, 104 ml of 10 mg / L methyl orange solution and add it to the reaction container, and react in the dark for 1 hour. The rate reached 54.5%.

Embodiment 3

[0032] a. Mix 15ml of tetra-n-butyl titanate and 10ml of absolute ethanol at room temperature, and stir for 20min to obtain a uniform and transparent yellow solution 1.

[0033] b. At room temperature, 0.7683g Ni(CH 3 COO) 2 .4H 2 O was dissolved in 5ml of absolute ethanol to form a green solution 2, which was added to 1 and stirred for 3h.

[0034] c. Slowly drop the acetic acid solution with pH=4 into the above mixed solution under stirring until a gel is formed.

[0035] d. The gel is dried in an oven at 90° C. to obtain a dry gel, which is ground into a powder.

[0036] e. Mix 0.8003 g of the above powder with 1.2006 g of urea, and calcinate at 400° C. for 5 hours to obtain a nitrogen-nickel co-doped titanium dioxide photocatalyst.

[0037] f. Take 0.1362g of the above-mentioned photocatalyst, 136ml of isatin solution of 10mg / L is added to the reaction container, react in dark for 1h, the light source is a 500W halogen lamp, after 70min of light, the decolorization rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com