Preparation method for boron nitride ceramics fibre precursor

A technology of ceramic fibers and precursors, applied in the chemical characteristics of fibers, textiles and papermaking, etc., can solve the problems of unfavorable spinning process and high viscosity, and achieve the effects of good wave permeability, easy separation and good spinnability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A kind of preparation method of boron nitride ceramic fiber precursor, concrete steps are:

[0028] The first step: the anhydrous toluene solution of 40wt% cyclic trichloroborazane (36.3g) is cooled to -80°C with the PSL-1800 type magnetic stirring cryogenic tank, and 40wt% methylamine is added dropwise under magnetic stirring conditions. In anhydrous toluene solution, white flocculent methyl ammonium chloride precipitates immediately. After the dropwise addition, the temperature is raised to -40°C, reacted for 1 hour, then warmed up to room temperature, reacted for 10 hours, filtered to remove the precipitate, and used Rinse the precipitate with water toluene once, combine the filtrates, and heat up to 60°C under a vacuum of 3 mmHg to remove part of the toluene, wherein the weight ratio of methylamine to cyclic trichloroborazane is 3:10;

[0029] The second step: use PSL-1800 type magnetic stirring low temperature tank and tetrafluoroethylene tube to condense boron tri...

Embodiment 2

[0033] A kind of preparation method of boron nitride ceramic fiber precursor, concrete steps are:

[0034]The first step: the anhydrous toluene solution of 45wt% cyclic trichloroborazane (36.3g) is cooled to-70 ℃ with refrigeration equipment, and the anhydrous toluene solution of 45wt% methylamine is added dropwise under magnetic stirring conditions, immediately There is a white flocculent precipitate of methyl ammonium chloride. After the dropwise addition, the temperature is raised to 0°C, reacted for 10 hours, then warmed up to room temperature, reacted for 20 hours, filtered to remove the precipitate, and washed with anhydrous toluene for 8 times. Combine the filtrates, heat up to 30°C under a vacuum of 5 mmHg to remove part of the toluene, wherein the weight ratio of methylamine to cyclic trichloroborazane is 2:5;

[0035] The second step: use refrigeration equipment and tetrafluoroethylene tubes to condense boron trichloride into anhydrous toluene solution of 45wt% methy...

Embodiment 3

[0039] A kind of preparation method of boron nitride ceramic fiber precursor, concrete steps are:

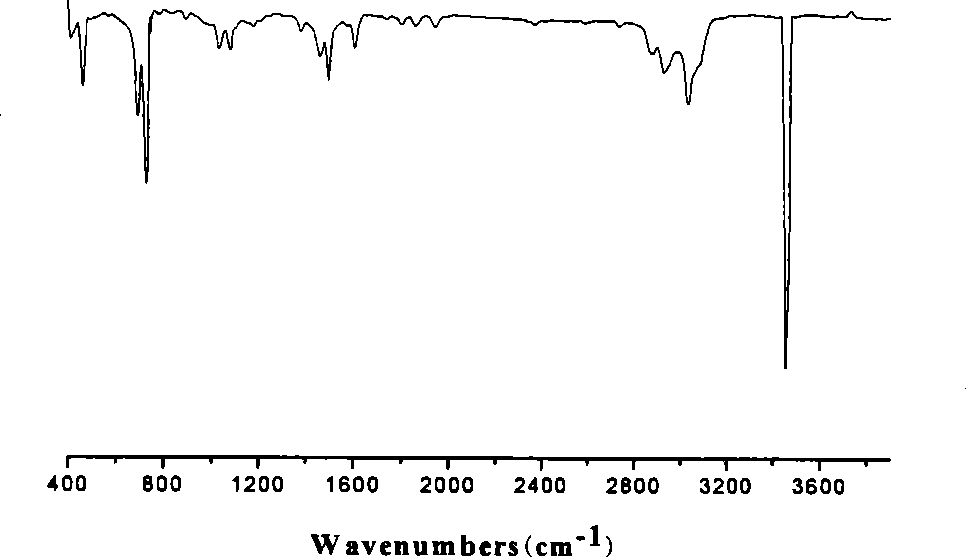

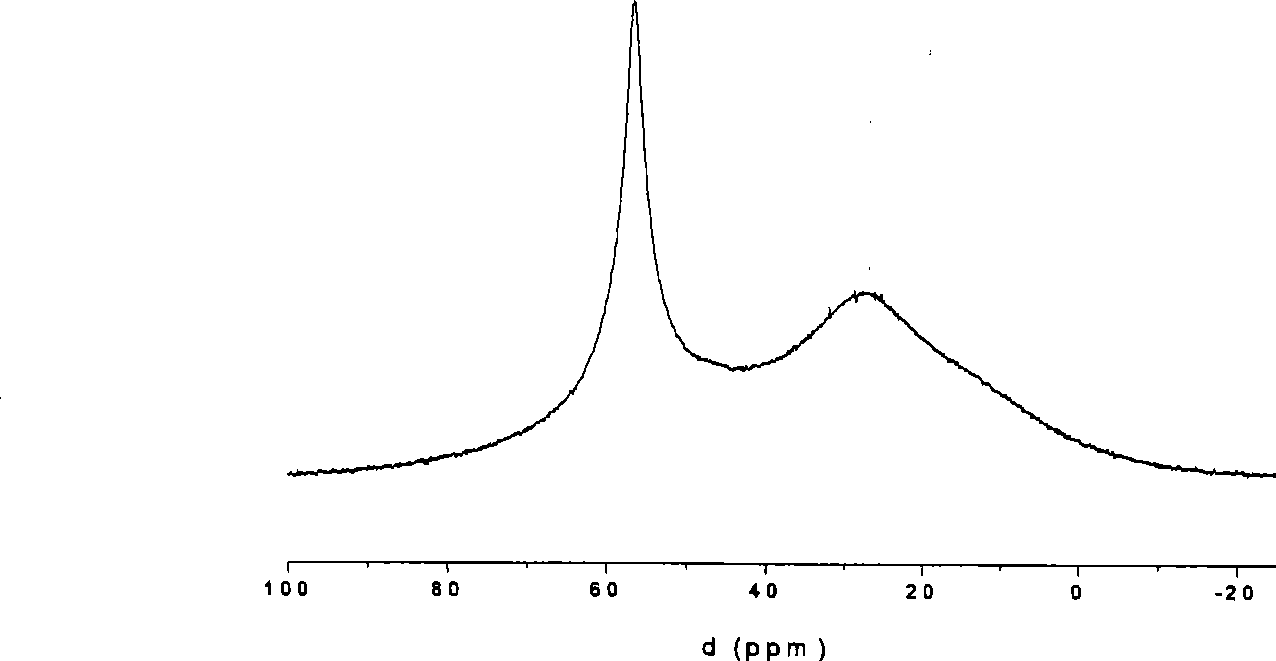

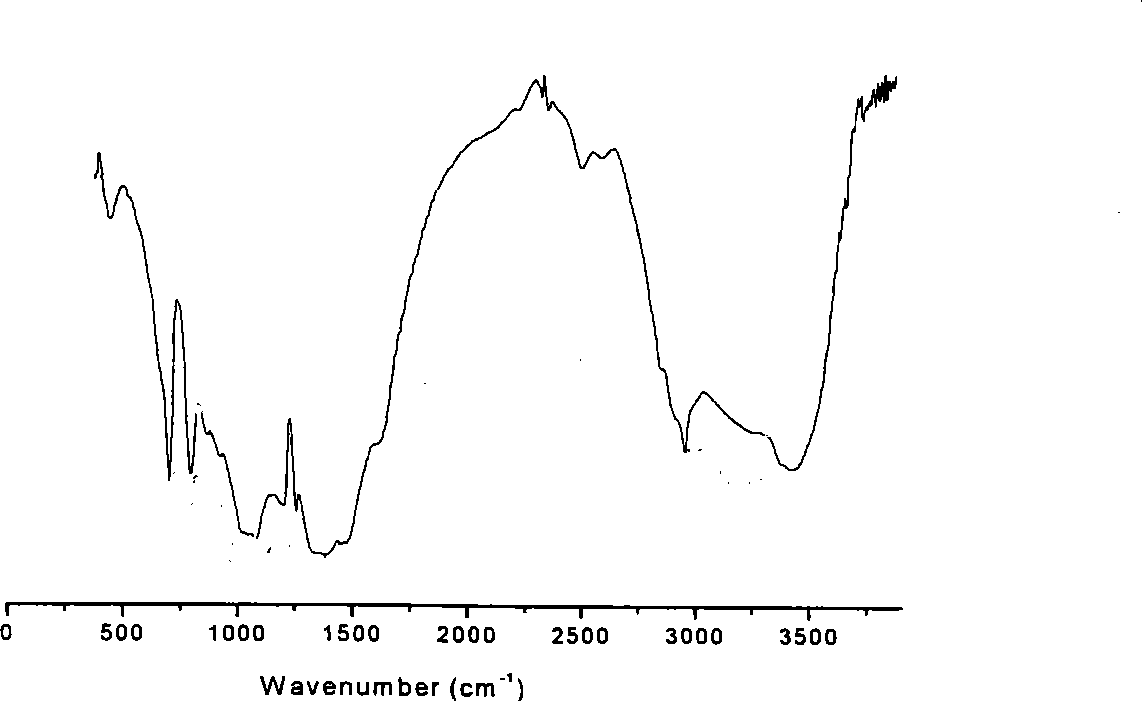

[0040] The first step is to synthesize small molecule monomer 1 according to the following method: the anhydrous toluene solution of 43wt% cyclic trichloroborazane (36.3g) is cooled to -75°C with refrigeration equipment, and 43wt % methylamine in anhydrous toluene solution, white flocculent methyl ammonium chloride precipitates immediately, after the dropwise addition, heat up to -20°C, react for 5 hours, then warm up to room temperature, react for 15 hours, filter to remove Precipitate, and wash the precipitate with anhydrous toluene 4 times, combine the filtrate, and heat up to 40 ° C under a vacuum of 4 mm Hg to remove part of the toluene, wherein the weight ratio of methylamine to cyclic trichloroborazane is 7:20 . like figure 1 Shown is the infrared spectrum of the small molecule monomer 1 obtained in the first step; figure 2 It is the NMR boron spectrum of the small mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com