Method for measuring crust amine and chitin content in crust amine fibre and cotton blending product

A technology of chitosan fibers and determination methods, which is applied in the direction of material analysis by observing the influence of chemical indicators, and analysis by making materials undergo chemical reactions, which can solve the problems of unfavorable environmental protection and the inability to effectively characterize chitosan and chitin. content, the toxicity of the solvent formic acid, etc., to achieve the effect of convenient operation, high measurement accuracy and accuracy, and low toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0017] The reagent preparation method used in the present invention is:

[0018] a. Preparation of PVSK solution: The relative molecular mass of PVSK chains is expressed in C 2 h 3 OSO 3 K is calculated as 162.204, weigh 0.422g, and make 1000ml solution with deionized water, the concentration is 0.0025mol / L.

[0019] b. Preparation of T.B indicator: Weigh 0.3g T.B and make 30ml solution with deionized water, the mass concentration is 0.1%.

[0020] (1) The steps for the determination of chitosan content in chitosan fiber and cotton blended products are:

[0021] a. Correctly weigh 1g of the substance to be tested after drying and constant weight to the accuracy of 0.01g, cut it into pieces and put it in a 200ml beaker, add 60 ~ 100ml of acetic acid solution with a concentration of 1.5% ~ 5%, put it into the rotor, and set it at 20 ~ Stir at a medium speed at 40°C to dissolve for 1-3 hours, let stand, and set aside.

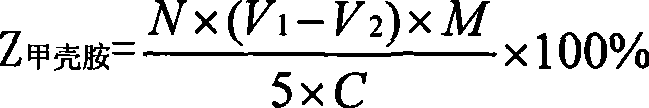

[0022] b. Use a pipette to transfer 5.0ml of the soluti...

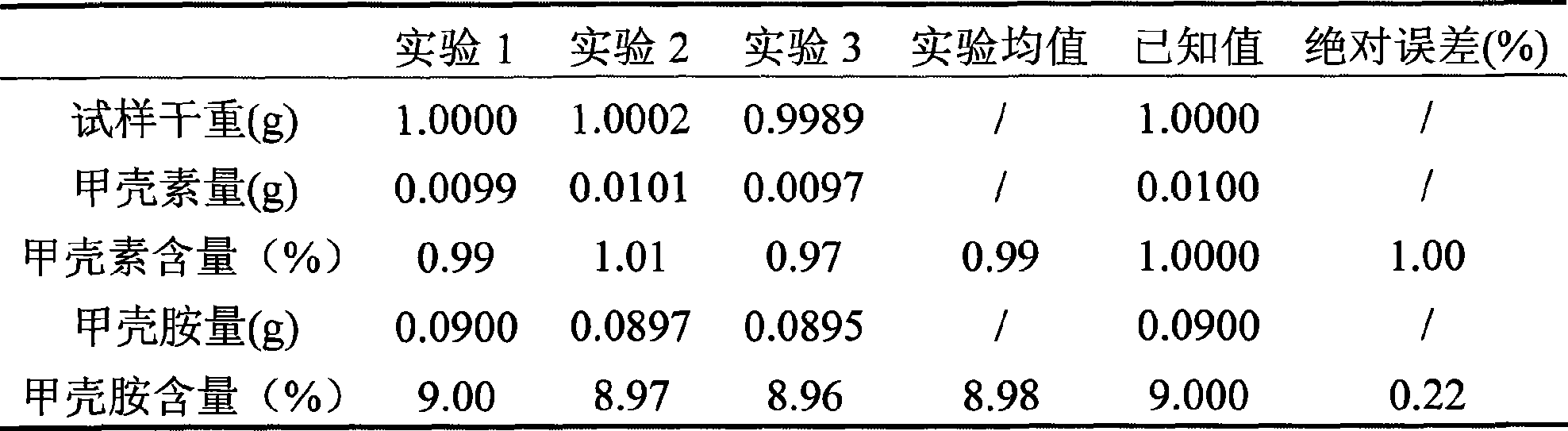

Embodiment 1

[0040] 1) Acetic acid solution with a concentration of 1.5% by weight dissolves chitosan fiber and cotton fiber with a chitosan content of 90% and a chitin content of 10% at a ratio of 10:90, chitosan fiber and cotton blended yarn The weight ratio of the weight to the acetic acid solution is 1:60; the dissolution temperature is 20°C, and the dissolution time is 1h, and the soluble chitosan fiber and the insoluble cotton fiber are separated to obtain the chitosan fiber solution, which is anionic polyelectrolyte polyvinyl potassium sulfate As a titrant, the cationic blue organic dye toluidine blue is used as an indicator, and the chitosan content in the chitosan fiber and cotton blended yarn is measured by colloid titration;

[0041] 2) Treat the chitosan fiber and cotton blended yarn to be tested with a sodium hydroxide solution with a concentration of 30% by weight, and the weight ratio of the chitosan fiber and cotton blended yarn to the sodium hydroxide solution is 1:40; The...

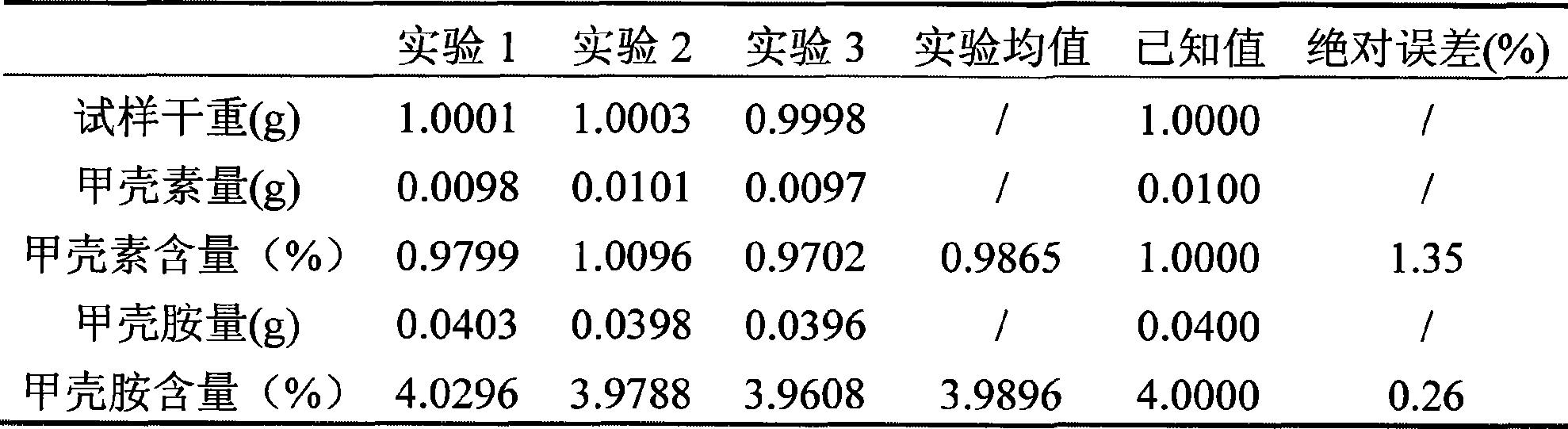

Embodiment 2

[0048] 1) Acetic acid solution with a concentration of 5% by weight dissolves chitosan fiber with 80% chitin content and 20% chitosan fiber and cotton fiber blended yarn at a ratio of 5:95, the weight of the chitosan fiber and cotton blended product The weight ratio with the acetic acid solution is 1:100; the dissolution temperature is 40°C, and the dissolution time is 3 hours to separate the soluble chitosan fibers and insoluble cotton fibers to obtain a chitosan fiber solution, which is titrated with the anionic polyelectrolyte potassium polyvinyl sulfate Agent, with cationic blue organic dye toluidine blue as indicator, adopt the colloid titration method to measure the content of chitosan in the chitosan fiber and cotton blended yarn;

[0049] 2) Treat the chitosan fiber and cotton blended yarn to be tested with a sodium hydroxide solution with a concentration of 45% by weight, and the weight ratio of the chitosan fiber and cotton blended yarn to the sodium hydroxide solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com