Poly-pyrrole and metal nanometer particle composite gas sensor and preparation thereof

A technology of metal nanoparticles and gas sensors, applied in the direction of material resistance, etc., can solve the problems of practical limitations, poor selectivity, low sensitivity, etc., and achieve the effects of strengthening, improving stability, and increasing body surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

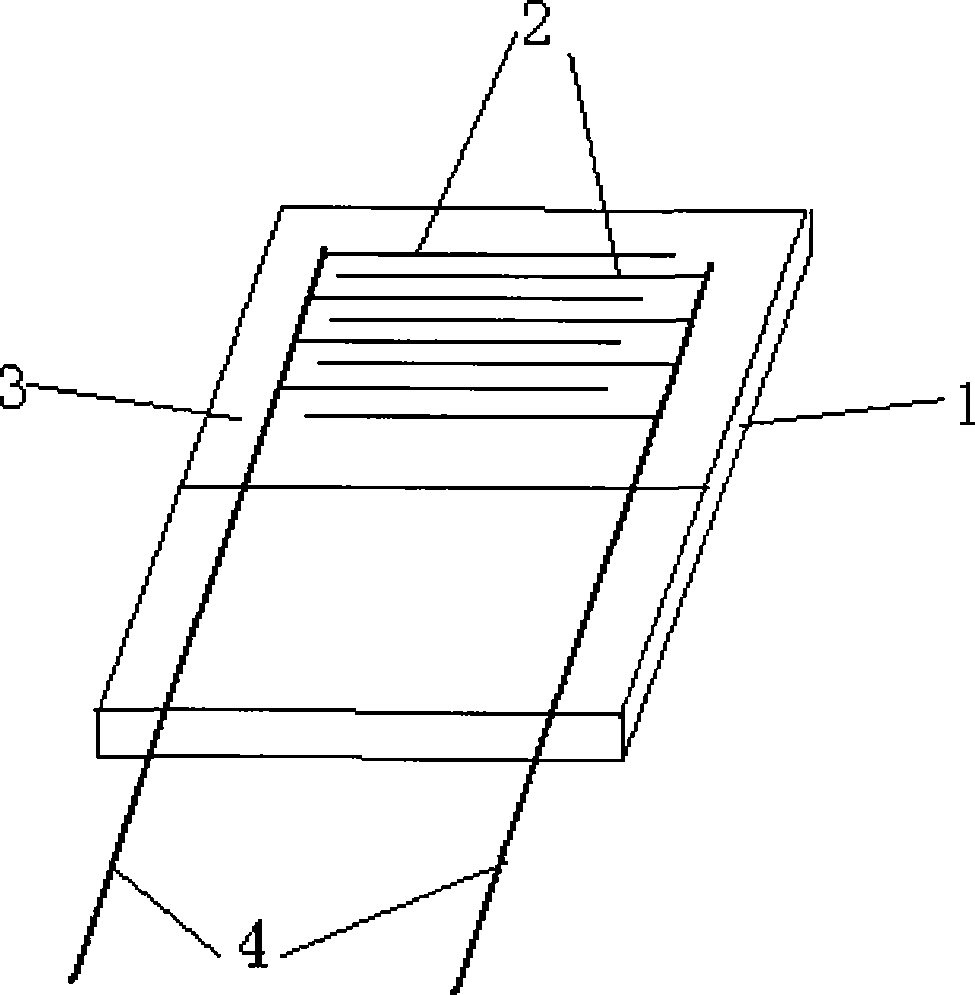

[0028] 1) Clean the surface photolithography and evaporate the ceramic substrate with interdigitated gold electrodes, and dry it for later use;

[0029] 2) Palladium chloride, sodium polystyrene sulfonate, and polyvinylpyrrolidone are added to deionized water, palladium chloride: sodium styrene sulfonate unit in sodium polystyrene sulfonate: vinylpyrrolidone unit in polyvinylpyrrolidone The molar ratio is 1:1:1, prepare a solution with a palladium chloride concentration of 0.0012mol / L, then add methanol to the solution, the volume ratio of methanol to deionized water is 1:0.5, and react at 50°C for 0.5h, Obtain the precursor solution.

[0030] 3) Add ammonium persulfate with a concentration of 0.005mol / L to the precursor solution prepared in step 2), and use a dipping machine to immerse the ceramic substrate with interdigitated gold electrodes in step 1) in the precursor solution for 0.5min, After being pulled out and dried in the air, it was gas-phase polymerized in saturate...

Embodiment 2

[0032] 1) cleaning the surface photolithography and evaporating the ceramic substrate with interdigitated gold electrodes, and drying for later use;

[0033] 2) Palladium chloride, sodium polystyrene sulfonate, and polyvinylpyrrolidone are added to deionized water, palladium chloride: sodium styrene sulfonate unit in sodium polystyrene sulfonate: vinylpyrrolidone unit in polyvinylpyrrolidone The molar ratio is 1:10:10, prepare a solution with a palladium chloride concentration of 0.0048mol / L, then add methanol to the solution, the volume ratio of methanol to deionized water is 1:4, and react at 80°C for 8h to obtain precursor solution.

[0034] 3) Ammonium persulfate with a concentration of 0.08mol / L was added to the precursor solution prepared in step 2), and the ceramic substrate with interdigitated gold electrodes in step 1) was immersed in the precursor solution for 8 minutes using a dipping machine to extract After being pulled out and dried, it was gas-phase polymerized...

Embodiment 3

[0036] 1) cleaning the surface photolithography and evaporating the ceramic substrate with interdigitated gold electrodes, and drying for later use;

[0037] 2) Palladium chloride, sodium polystyrene sulfonate, and polyvinylpyrrolidone are added to deionized water, palladium chloride: sodium styrene sulfonate unit in sodium polystyrene sulfonate: vinylpyrrolidone unit in polyvinylpyrrolidone The molar ratio is 1:5:2.5, prepare a solution with a palladium chloride concentration of 0.0024mol / L, then add methanol to the solution, the volume ratio of methanol to deionized water is 1:2, and react at 60°C for 4h to obtain precursor solution.

[0038] 3) Add ammonium persulfate with a concentration of 0.02mol / L to the precursor solution prepared in step 2), and use a dipping machine to immerse the ceramic substrate with interdigitated gold electrodes in step 1) in the precursor solution for 4 minutes to improve After being pulled out and dried, it was gas-phase polymerized in satura...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Interdigital width | aaaaa | aaaaa |

| Interdigital gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com