Preparation method for lithium battery anode material LiFePO4 nano-powder body

A cathode material and nano-powder technology, applied in the field of lithium battery cathode material preparation, can solve problems such as unfavorable large-scale application, high equipment performance requirements, unfavorable large-scale production, etc., and achieve low cost, no environmental pollution, and reduced consumption. and the effect of emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

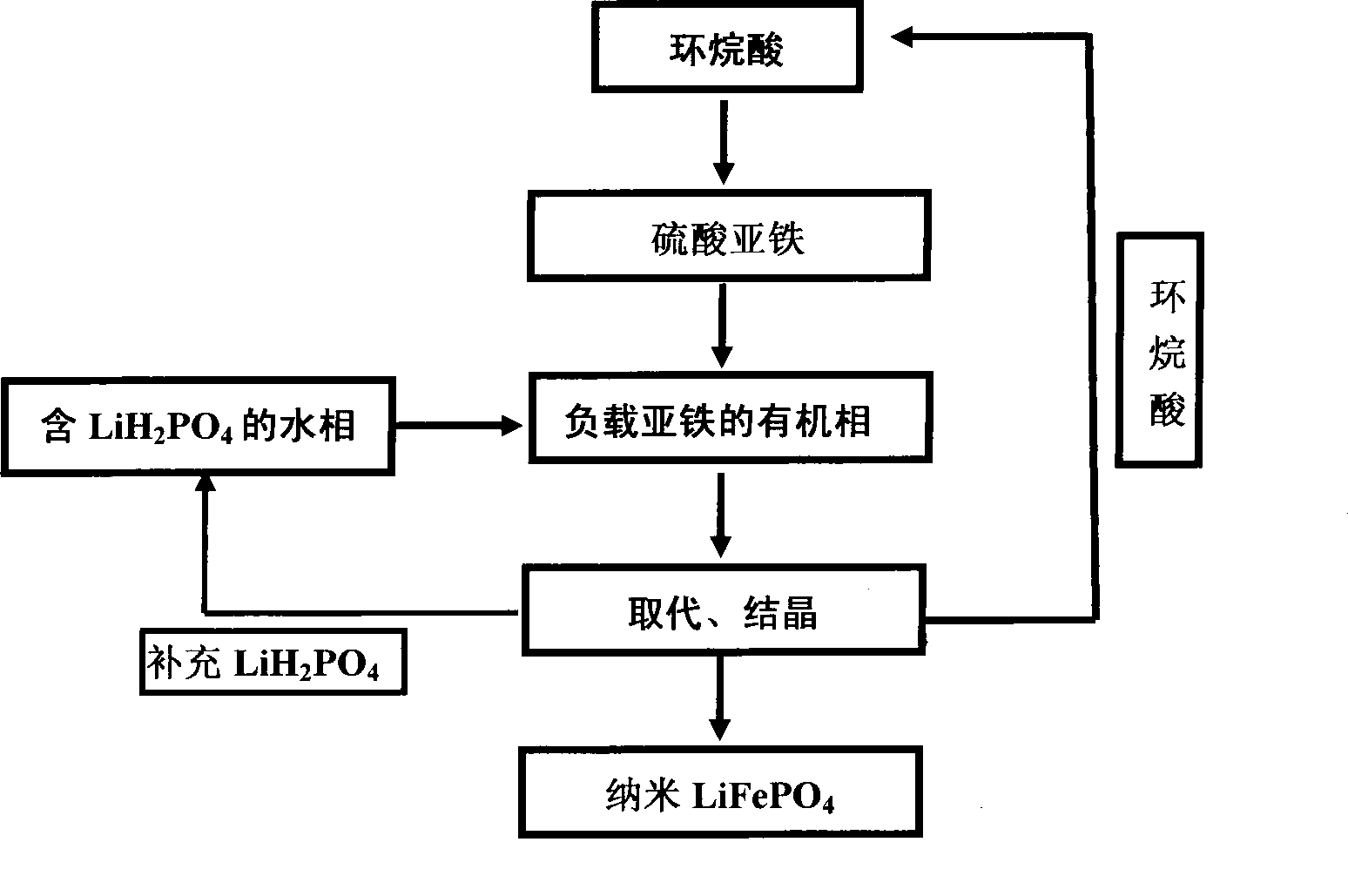

[0033] LiFePO, a cathode material for lithium batteries 4 The preparation method of nanopowder is made up of following steps:

[0034] (1) Preparation of organic phase

[0035] Add naphthenic acid and isooctyl alcohol with an average molecular weight of 330 to the Erlenmeyer flask in a volume ratio of 2:1:1 and mix well, then add 0.1mol.L -1 Aqueous solution of ferrous sulfate, under magnetic stirring, add ammonia water to adjust the pH value to 6, continue to stir for 0.5 hours, pour the mixed solution into the separatory funnel, after standing still for 5 minutes, the solution is divided into upper and lower 2 phases at this time, separate the organic phase, Wash the organic phase 3 times with distilled water and then separate the liquid, then collect the organic phase;

[0036] (2) Preparation of water phase

[0037] Weigh 0.839g LiOH, add 6.66ml of 3mol / L H 3 PO 4 In the aqueous solution, add water to 20ml, and then add 0.167g LiOH after it is completely dissolved, ad...

Embodiment 2

[0045] A lithium battery positive electrode material LiFePO 4 The preparation method of nanopowder is made up of following steps:

[0046] (1) Preparation of organic phase

[0047] Add naphthenic acid and isooctyl alcohol with an average molecular weight of 350 in sequence in the conical flask at a volume ratio of 2:1:1, and then add 0.05mol L -1 ferric sulfate aqueous solution, adjust the pH value to 2 with ammonia water or hydrochloric acid aqueous solution, magnetically stir for about 0.5 hours, pour the mixed solution into a separating funnel, and separate the liquid after standing still for 10 minutes. At this time, the solution is divided into upper and lower phases, and the organic phase is separated. Phase, wash the organic phase twice with distilled water and then separate the liquid, then collect the organic phase;

[0048] (2) Preparation of water phase

[0049] Weigh 0.839g LiOH, add 6.66ml of 3mol / L H 3 PO 4 In the aqueous solution, add water to 20ml, and the...

Embodiment 3

[0057] A lithium battery positive electrode material LiFePO 4 The preparation method of nanopowder is made up of following steps:

[0058] (1) Preparation of organic phase:

[0059] Under stirring, mix naphthenic acid with an average molecular weight of 200 and isooctyl alcohol at a ratio of 1:3:5 by volume, and then add 0.01mol·L -1 ferrous sulfate aqueous solution, continue to stir, adjust the pH value to 6 with ammonia water or hydrochloric acid aqueous solution, continue to stir for 0.6 hours, pour it into the liquid separator, and let it stand for 5 minutes. At this time, the solution is divided into upper and lower phases, and the organic phase is separated. Phase, wash the organic phase twice with distilled water and then separate the liquid, then collect the organic phase;

[0060] (2) Preparation of water phase:

[0061] 0.5g of LiH 2 PO 4 Dissolve in 10ml of water and stir evenly to obtain the water phase;

[0062] (3) Substitution reaction and crystal formatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com