Method for preparing fine line flexible circuit board with high peeling strength

A flexible circuit board and manufacturing method technology, which are applied in secondary processing of printed circuits, ion implantation plating, improvement of metal adhesion of insulating substrates, etc., can solve the problems of extremely high substrate requirements, limited market application, and high overall cost , to achieve the effect of high material utilization, improved drilling quality and high peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for manufacturing a thin circuit flexible circuit board with high peel strength, comprising the following steps:

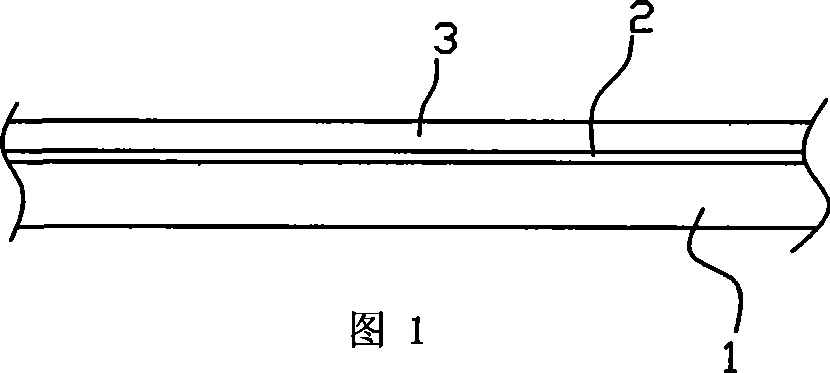

[0028] 1), the formation of thin copper with aluminum foil (see Figure 1): select aluminum foil (1) as the carrier, the thickness of the aluminum foil is 8um to 50um, preferably 8um or 12um or 20um or 35um or 50um, and the width is 100mm to 1000mm, Preferably 100mm or 250mm or 500mm or 750mm or 1000mm, vacuum sputtering a layer of sputtered copper layer (2) that can improve the peel strength of thin copper and the carrier on one side of the aluminum foil, the thickness of the sputtered copper layer is 100mm angstroms to 300 angstroms, preferably 100 angstroms or 150 angstroms or 300 angstroms, and then roll-shaped electroplating thin copper layer (3) on the sputtered copper layer, the thickness of the thin copper layer is 2um to 35um, preferably 2um or 5um or 9um or 12um.

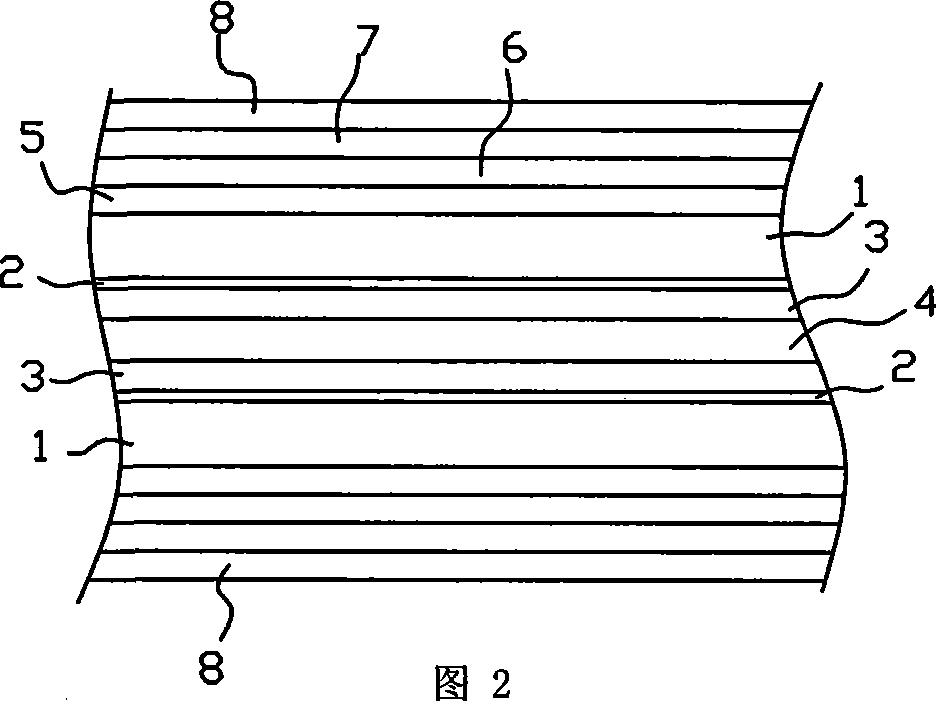

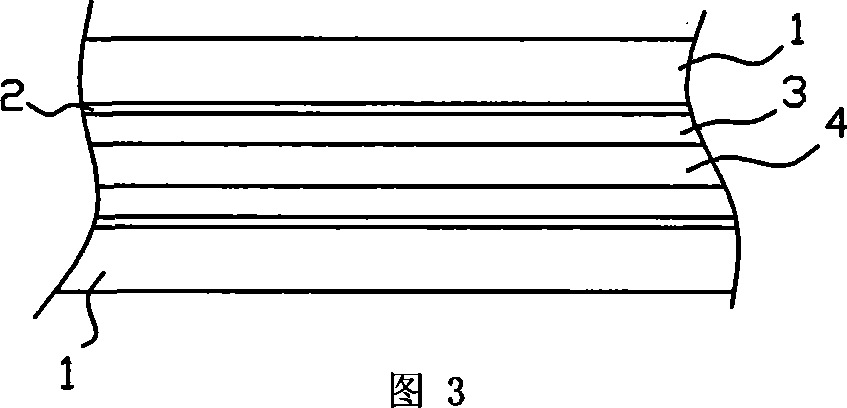

[0029] 2) Production of copper-clad laminates with aluminum foil (see Figu...

Embodiment 2

[0037] The difference from the above implementation is that in step 1), aluminum alloy foil or nickel foil or nickel alloy foil is selected as the carrier, and the following procedures are the same as in the first embodiment.

Embodiment 3

[0039] The difference from the first embodiment lies in step 1), the sputtered metal layer (2) is manganese or iron or tungsten or nickel or chromium or nickel-chromium alloy, and the following steps are the same as the first embodiment.

[0040]The present invention adopts the sputtering method to form the sputtering layer, the thickness of the sputtering layer will not change due to the roughness of the carrier metal foil, and finally ensures the uniformity of the peeling strength. In addition, the sputtering layer is made of one kind of metal. The present invention does not need to consider the two characteristics of high peel strength and easy peeling at high temperature. Considering the actual circuit board manufacturing process requirements, only high peel strength is considered, which improves the quality more effectively. The stability of the carrier metal foil is corroded after drilling in the circuit board processing process, which has the effect of improving the qual...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com