Calcium orthophosphate porous particle material with biological activity as well as preparation method and use thereof

A porous particle and biologically active technology, applied in the field of biomedical materials and regenerative medicine, can solve the problems of limited bone damage speed coordination and matching, and achieve the effect of simple process, uniform size, and easy control of doping rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

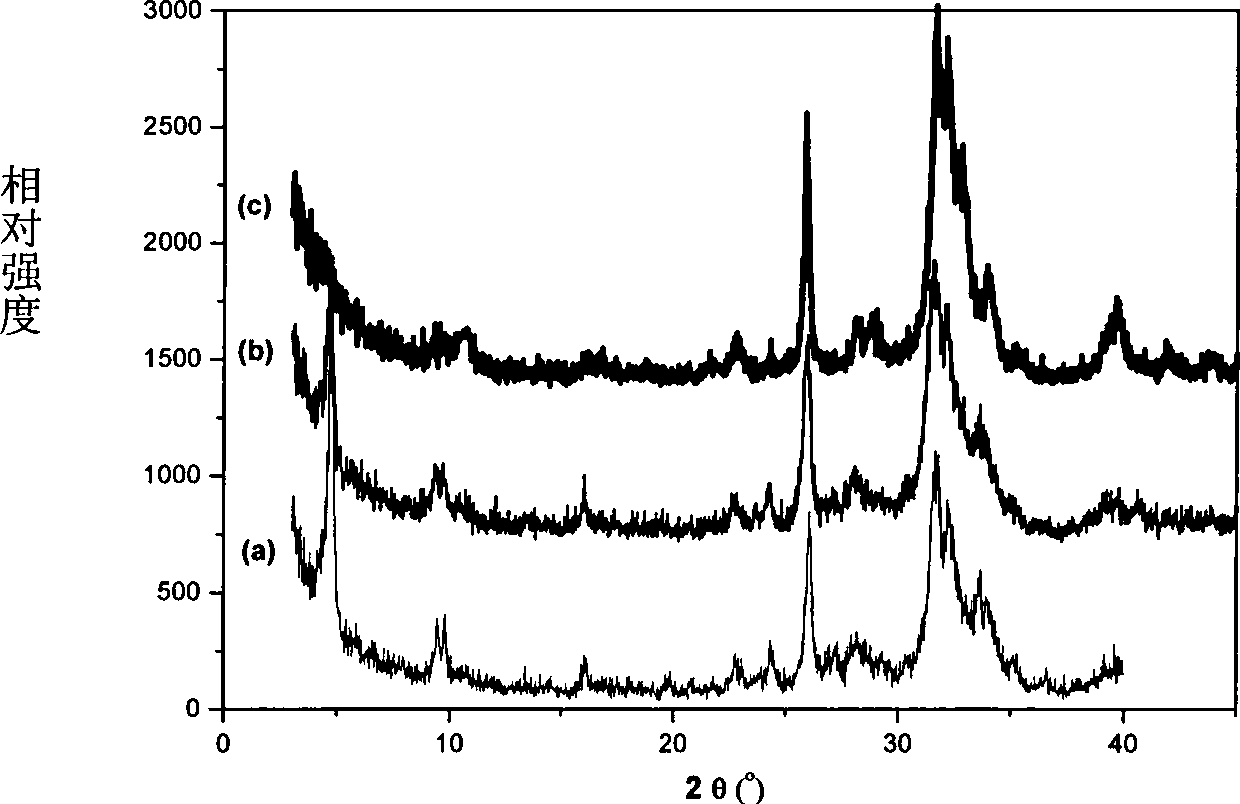

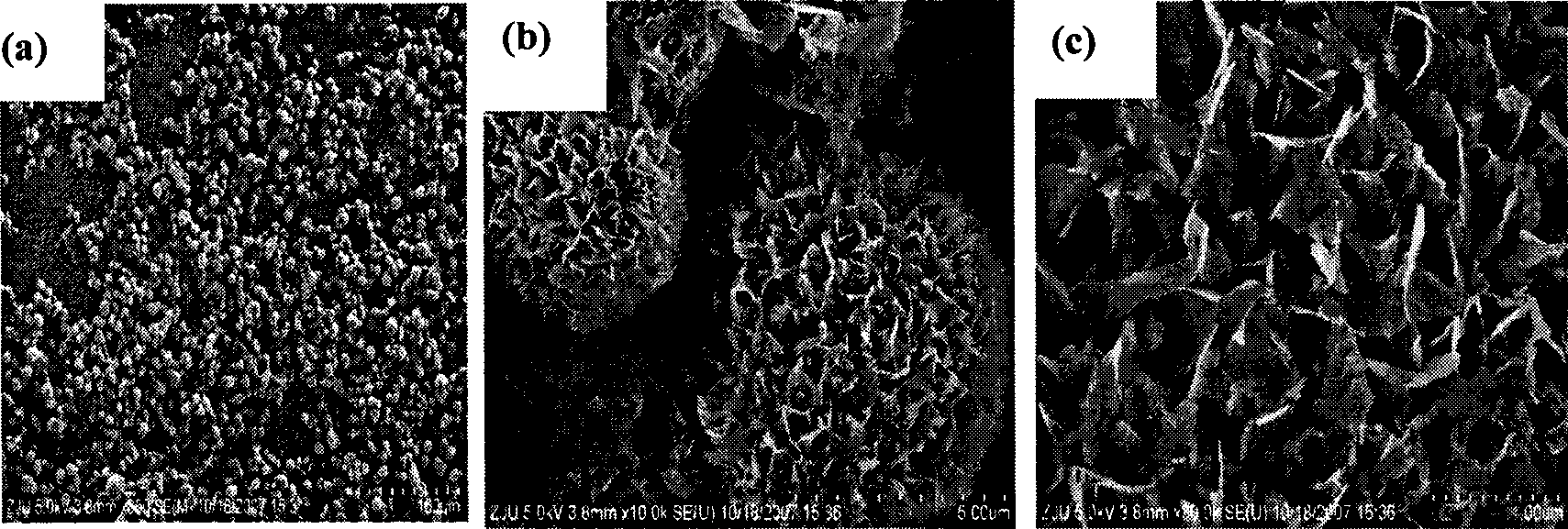

[0040] Add 474 mL of deionized water into a three-neck flask with a capacity of 1000 mL, place it in a water bath at 60° C. with continuous mechanical stirring (650 rpm) and heat up, then add 40 μL of an aqueous solution of sodium polyaspartate with a concentration of 10 wt % and a concentration of 0.25 mol / 1.0 mL of sodium silicate solution in L, and 25 mL of sodium phosphate solution with a concentration of 0.5 mol / L was added. After the mixed solution reached 60°C and stabilized, the pH value of the above mixed solution was adjusted to 5.0 with dilute HCl and NaOH solution; then 0.5mol / L Ca(CH 3 COO) 2 ·H 2 O solution 30.25mL and SrCl 2 , Zn(NO 3 ) 2 and MgCl 2 Dilute 1.0 mL of the original solution with a concentration of 0.25 mol / L to prepare a 500 mL aqueous solution, and slowly add it dropwise to a three-necked flask; After 6, 6.5 and 16 hours, part of the solution was sucked out, and after filtration, the microsphere particles were washed with deionized water an...

Embodiment 2

[0045] Add 474 mL of deionized water to a three-necked flask with a capacity of 1000 mL, place it in a water bath at 37° C. with continuous mechanical stirring (450 rpm) and heat up, then add 40 μL of an aqueous solution of sodium polyaspartate with a concentration of 10 wt % and a concentration of 0.25 mol / 2.5mL of sodium silicate solution in L, and 50mL of sodium phosphate solution with a concentration of 0.5mol / L was added, and after the mixed solution reached 37°C and stabilized, the pH value of the above mixed solution was adjusted to 6.5 with dilute HCl and NaOH solution; then 0.5mol / L Ca(CH 3 COO) 2 ·H 2 O solution 49mL and SrCl 2 , Zn(NO 3 ) 2 and MgCl 2 Dilute 1.0 mL of each original solution with a concentration of 0.25 mol / L to prepare a 500 mL aqueous solution, and slowly add it dropwise into a three-necked flask; after adding the mixed solution containing the above trace elements, continue to stir and age for 3 hours, and then filter The microsphere particl...

Embodiment 3

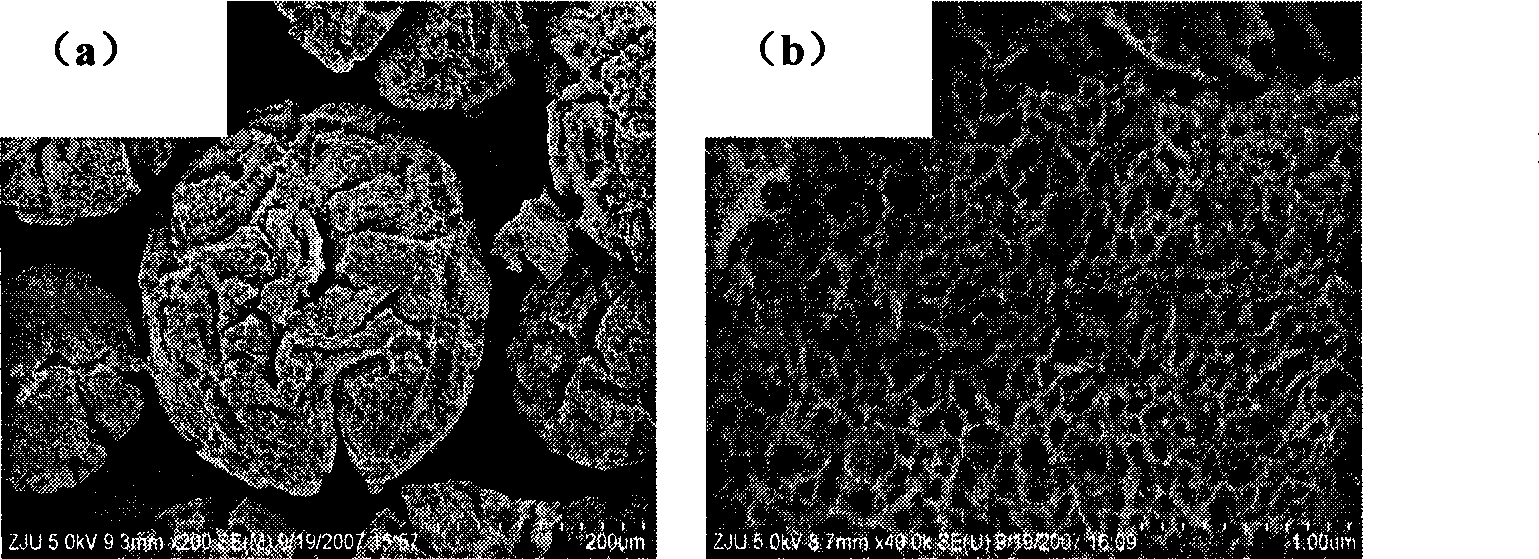

[0048] With embodiment 1, difference is that stirring velocity is 550rpm, and concentration is that the sodium silicate solution add-on of 0.25mol / L is 0.5mL, and concentration is the Ca(CH of 0.50mol / L 3 COO) 2 ·H 2 O solution 23.75mL, after aging for 3 hours, the morphology of microsphere particles is as follows Figure 4 As shown in (a), the particle size is 80 to 150 μm. SiO in microsphere particles after aging for 3.5 and 6.5 hours 2 Contents are 0.25wt% and 0.29wt%, zinc, strontium and magnesium content such as Figure 6 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com