Halogen-free flame-proof epoxy resin composition and bonding sheet and copper clad laminate prepared thereby

A technology of epoxy resin and composition, applied in the fields of halogen-free flame retardant epoxy resin composition, adhesive sheet for printed circuit and copper clad laminate, can solve the problem of poor heat resistance of the board, high brittleness of the board, and processing problems. To solve problems such as poor performance, it can achieve the effect of low water absorption, good processing performance and low thermal expansion coefficient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

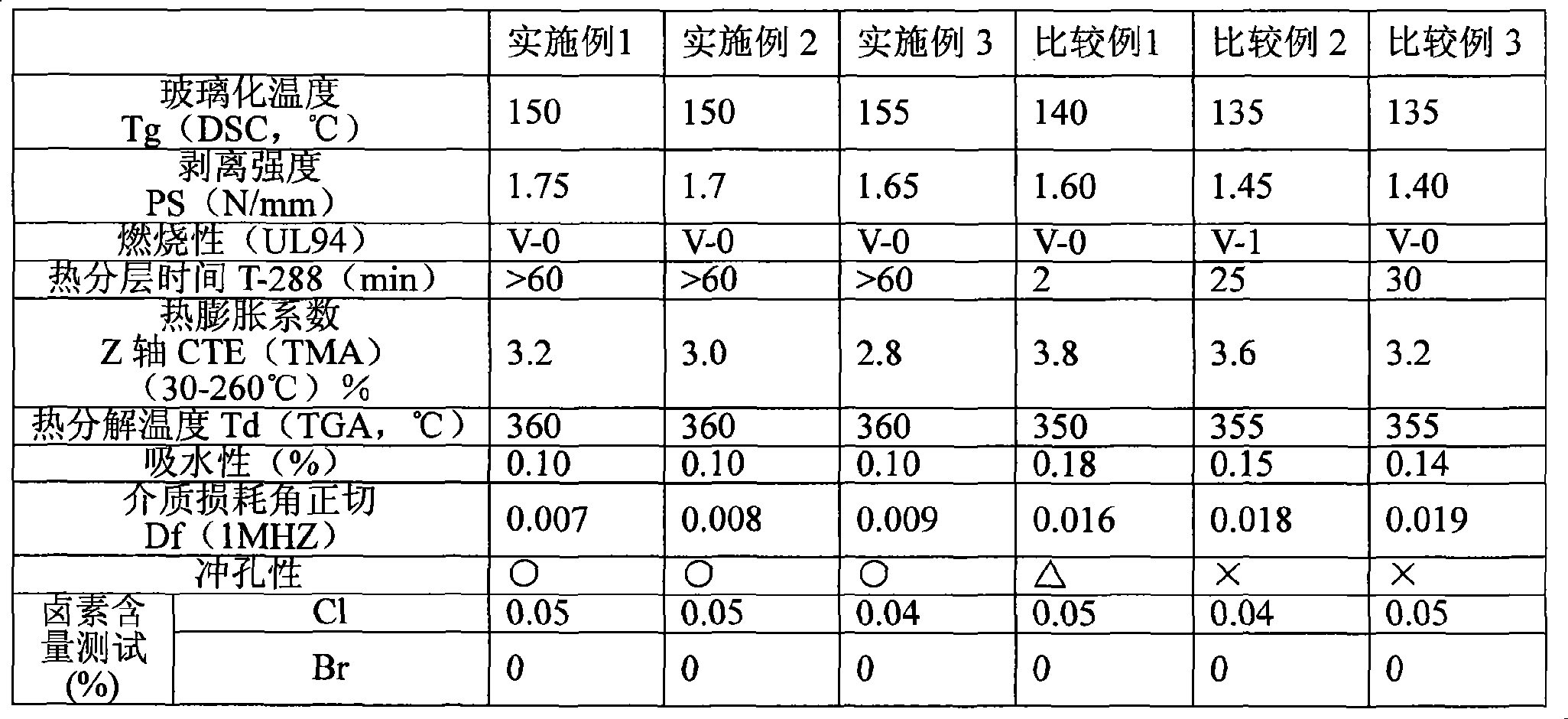

Examples

Embodiment 1

[0033] Embodiment 1: Weigh 70 parts by weight of bisphenol F type benzoxazine, 30 parts by weight of phenolic resin and 0.1 part by weight of 2-methylimidazole, mix the raw materials with acetone as solvent, and prepare a solid content of 65 % resin solution.

[0034] Dip eight sheets of 7628E glass fiber cloth into the resin solution for gluing, bake in an oven at 170°C for 8 minutes to make a semi-cured adhesive sheet for printed circuit.

[0035] Then, the eight printed circuits are superimposed with adhesive sheets, covered with a 35 μm electrolytic copper foil on the upper and lower sides, and hot-pressed in a vacuum press for 90 minutes under the conditions of temperature 190°C and pressure 35Kgf / cm2 to obtain Copper clad laminates for printed circuits with a thickness of 1.6 mm.

Embodiment 2

[0036] Embodiment 2: Weigh 50 parts by weight of bisphenol F type benzoxazine, 20 parts by weight of phenolic resin, 30 parts by weight of silicon dioxide and 0.1 part by weight of 2-methylimidazole, and use acetone as solvent after mixing the raw materials , Prepared into a resin solution with a solid content of 65%.

[0037] The production of the bonding sheet for the printed circuit and the copper-clad laminate is the same as in Example 1.

Embodiment 3

[0038] Embodiment 3: take by weighing 40 parts by weight of bisphenol F type benzoxazine, 10 parts by weight of phenolic resin, 30 parts by weight of silicon dioxide, 20 parts by weight of magnesium hydroxide and 0.2 parts by weight of 2-methylimidazole, the After the raw materials are mixed, acetone is used as a solvent to prepare a resin solution with a solid content of 65%.

[0039] The production of the bonding sheet for the printed circuit and the copper-clad laminate is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com