Electrostatic chuck

An electrostatic chuck and electrostatic attraction technology, applied in the field of microelectronics, can solve the problems that the insulating layer 1 cannot obtain enough heat and cannot heat up.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

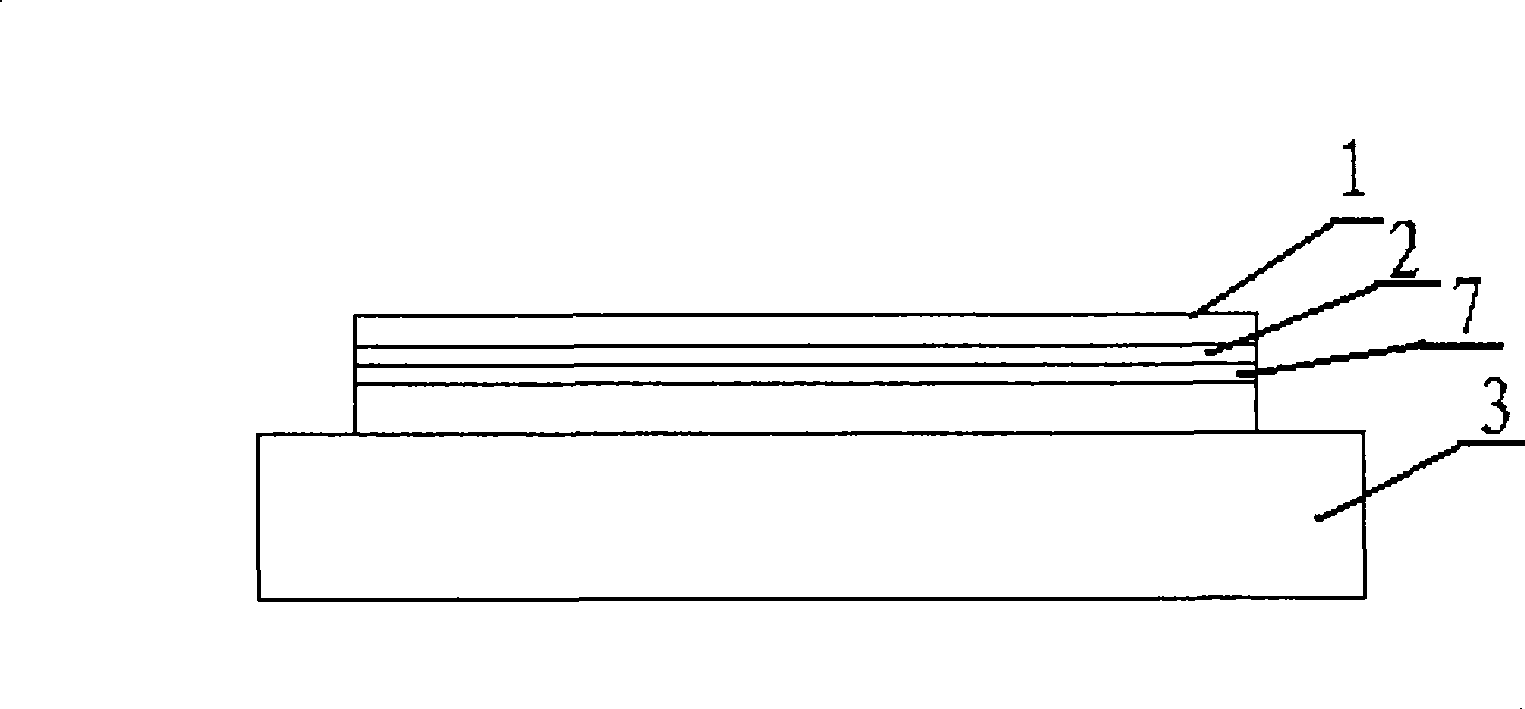

[0023] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the electrostatic chuck provided by the present invention will be described in detail below with reference to the accompanying drawings.

[0024] The present invention fully considers the influencing factors of heat conduction, and blocks the heat generated by the heater from conducting to the base by setting a heat insulating layer between the heater and the base, so that the processed devices such as wafers on the electrostatic chuck have A sufficiently large heating rate and good zone temperature control can further improve the uniformity of processing (for example, etching) of processed devices such as wafers.

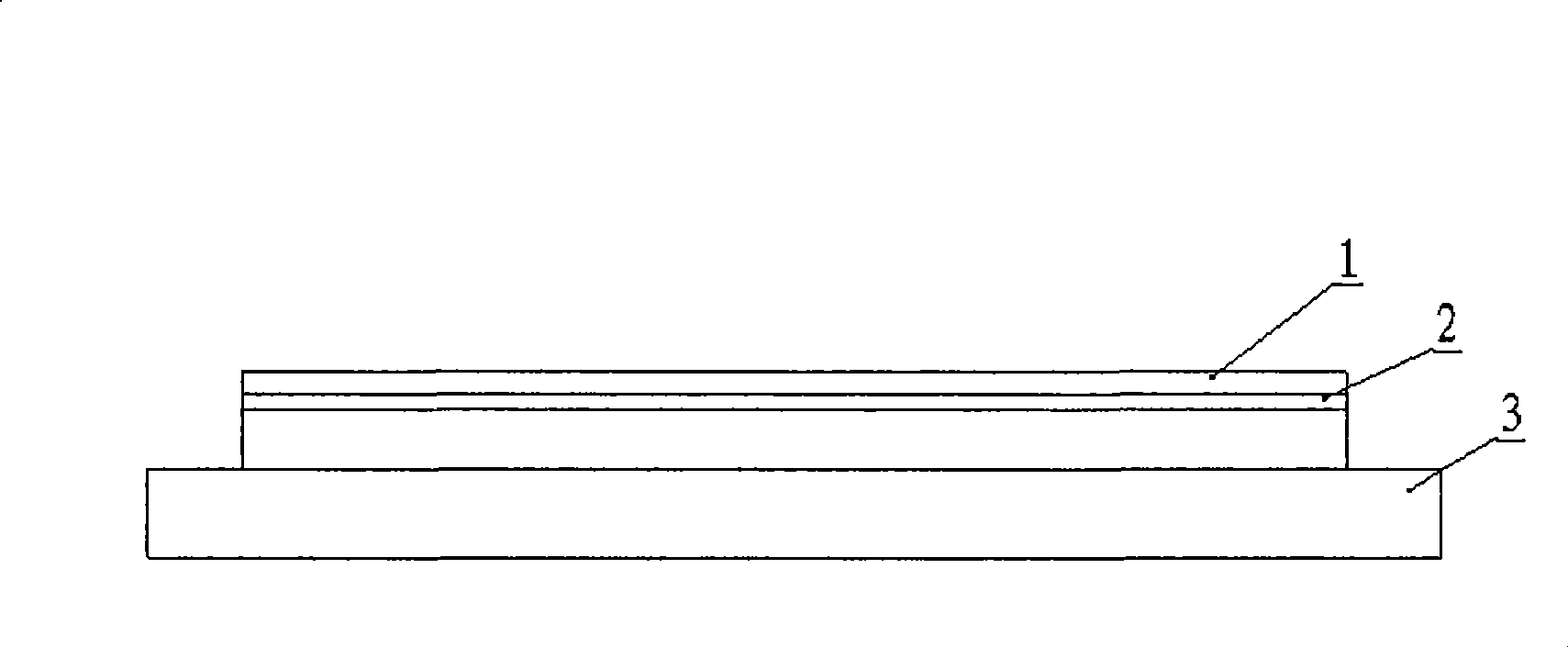

[0025] see image 3 , The electrostatic chuck in the first embodiment of the present invention includes an insulating layer 1 , a heater 2 , a heat insulating layer 7 and a base 3 in order from top to bottom.

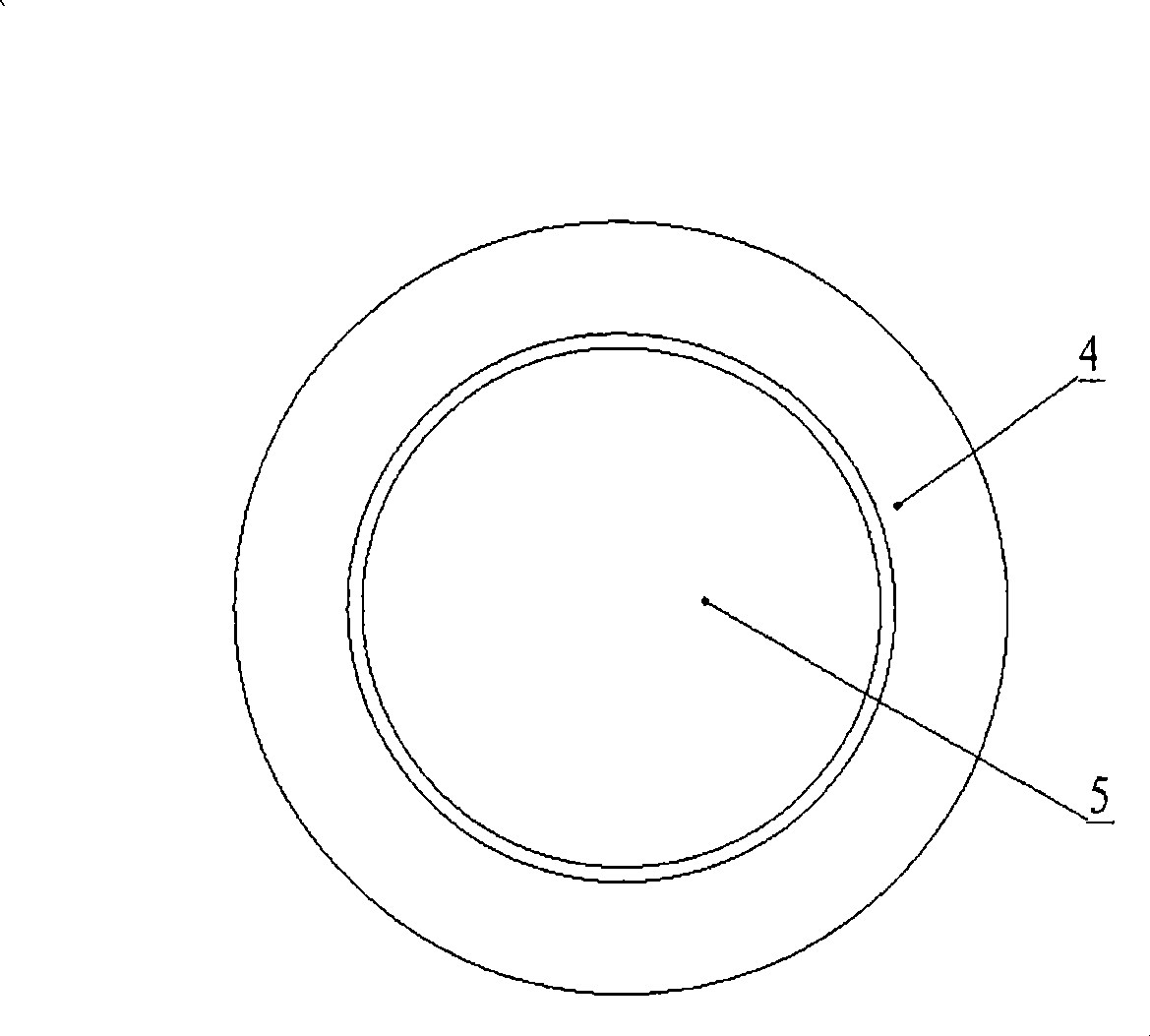

[0026] where, similar to figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com