Darlington tube with high reliability for selsyn module and preparation method thereof

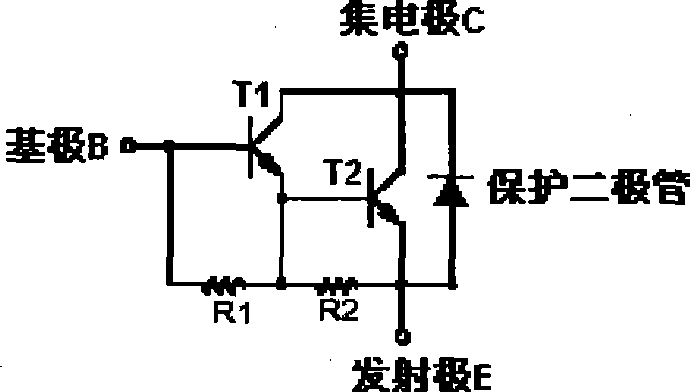

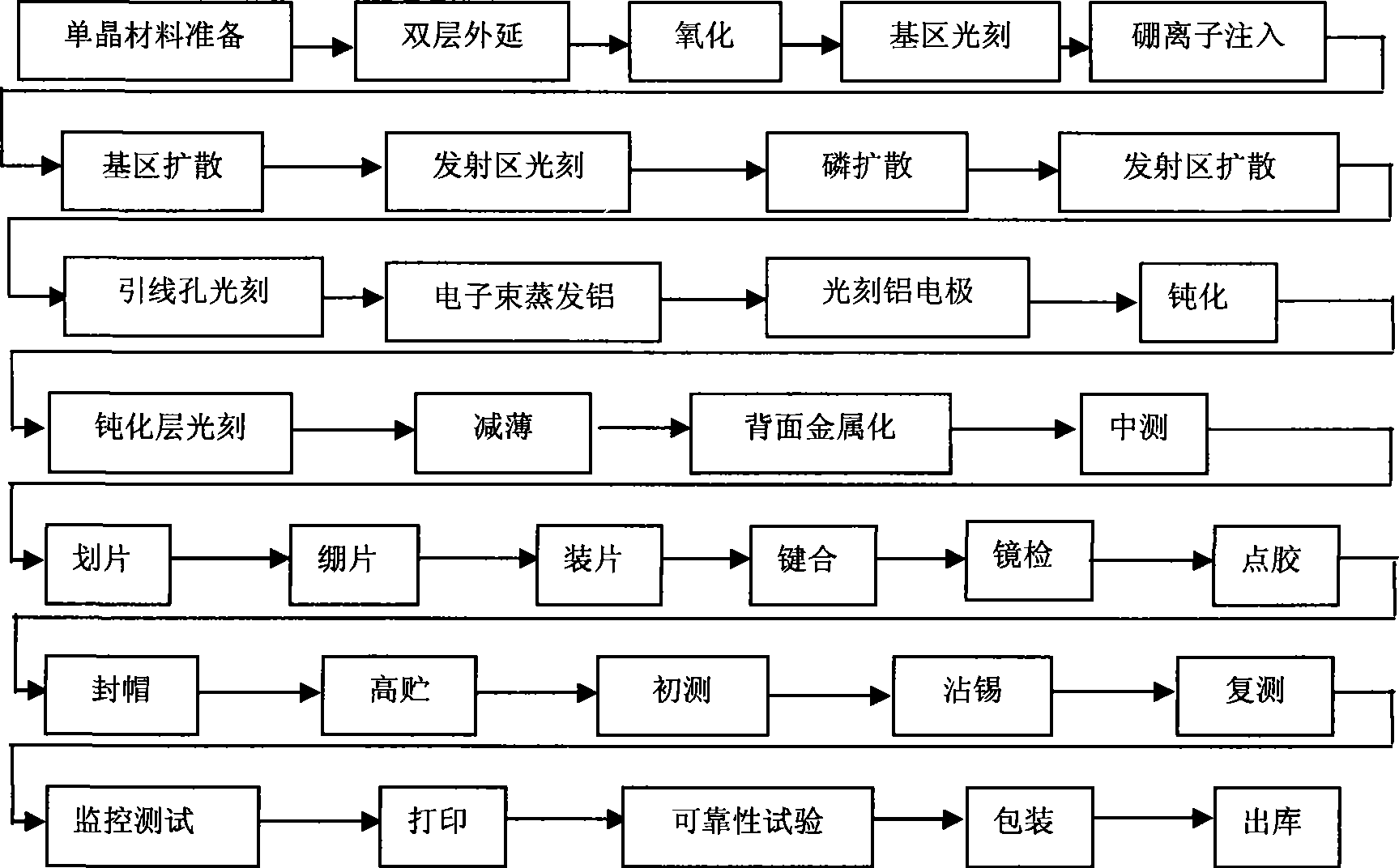

A self-aligning machine, Darlington tube technology, applied in the direction of semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc. Improve the switching parameters and secondary breakdown resistance, improve the anti-burning performance, and prevent the oxidation of the metal welding layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

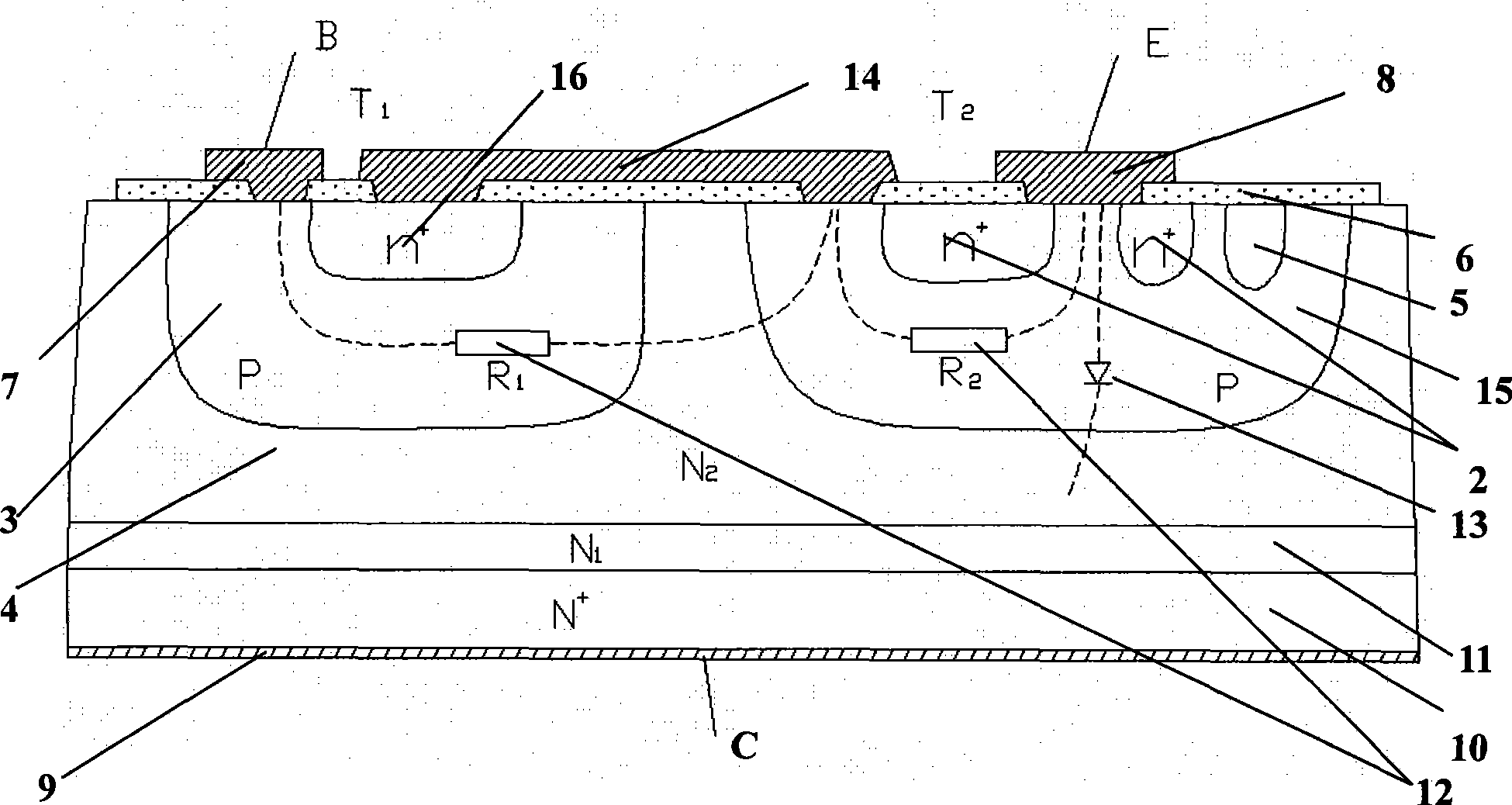

[0038] As shown in the figure: the transistor includes a base 18 and a die 20, and the die 20 includes a base region 3 of a previous transistor and a base region of a subsequent transistor formed in the high-resistance second epitaxial layer 4 of the collector region 15. There is a front-stage transistor emitter area 16 in the front-stage transistor base area 3, a rear-stage transistor emitter area 2 in the rear-stage transistor base area 15, and a rear-stage transistor base area 15 next to the rear-stage transistor emitter area 2 There is a voltage guard ring 5, on the same side of the high-resistance second epitaxial layer 4 of the collector region, the base region 3 of the previous transistor and the base region 15 of the transistor of the subsequent stage, and the emitter region 16 of the transistor of the former stage and the emitter region 2 of the transistor of the latter stage A protective silicon dioxide film 6 is provided on the surface; and the base aluminum layer 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com