Optical information recording medium, method of manufacturing same, and recording method

A technology for recording media and optical information, applied in the direction of optical recording/reproduction/erasing methods, optical recording carriers, optical recording systems, etc., can solve the problem of difficult light and dark identification of optical discs and photodetectors that cannot obtain push-pull values, and cannot focus Follow-up and other problems, achieve good NPPb characteristics, easy high-speed recording, and achieve high-speed recording effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

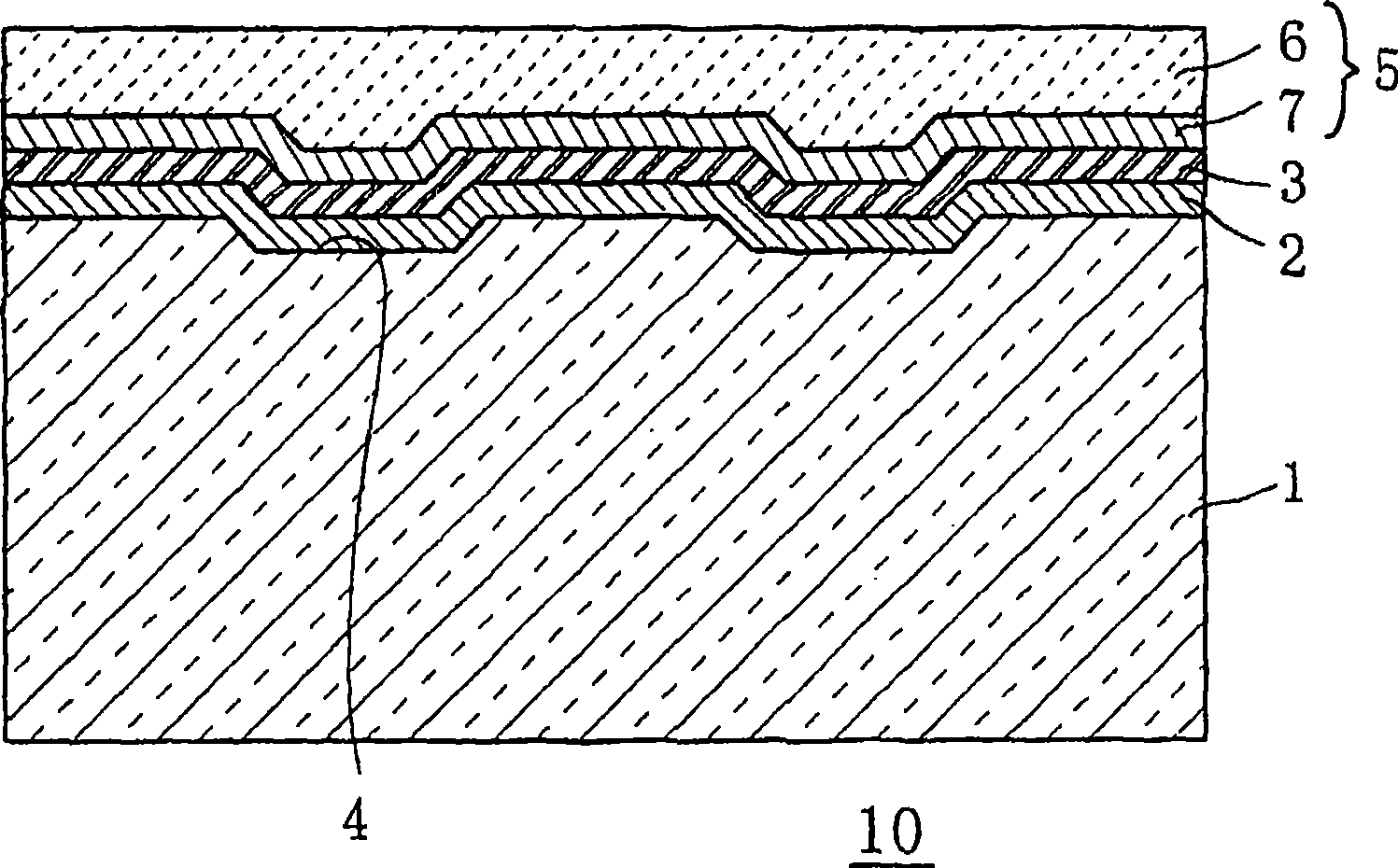

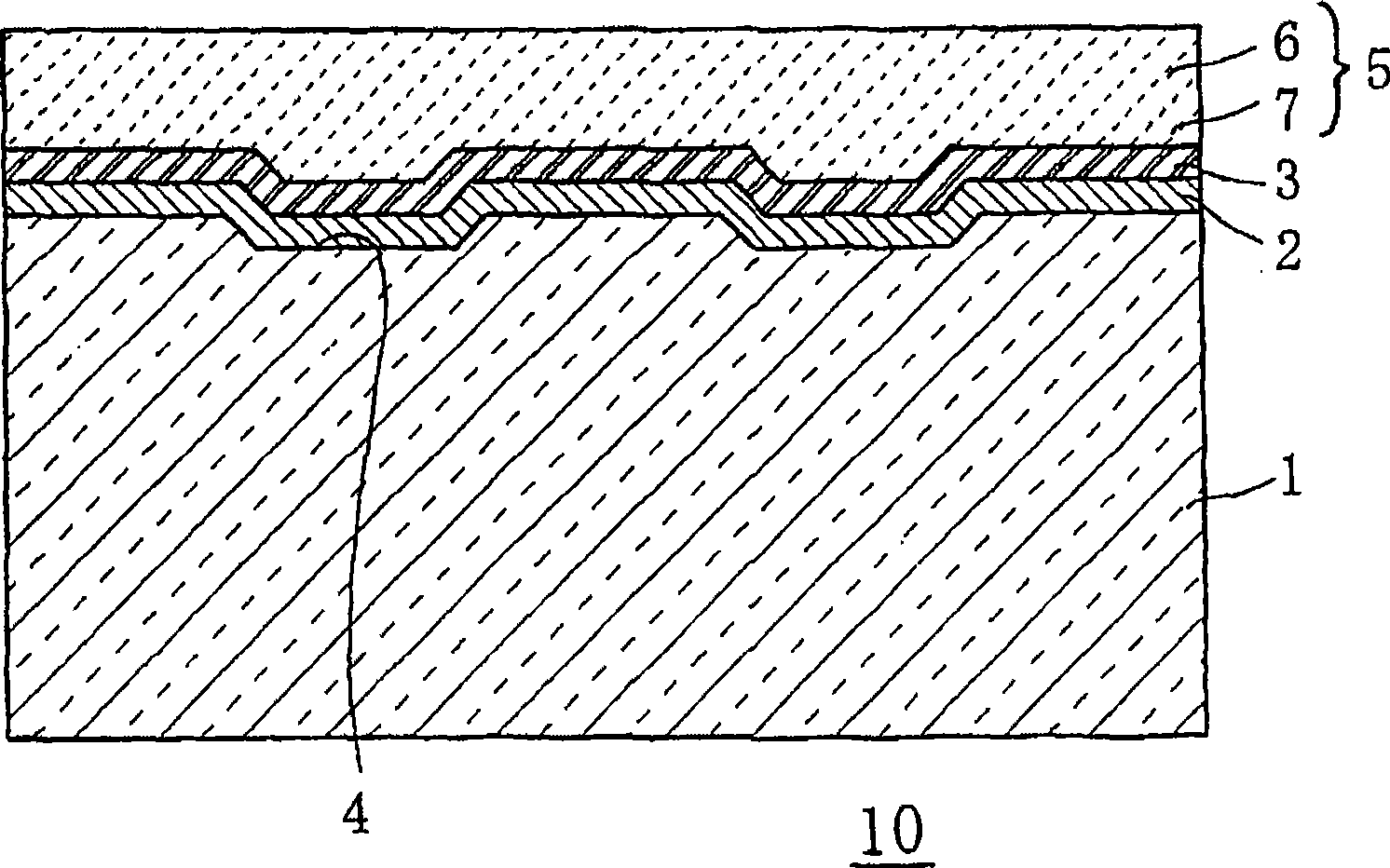

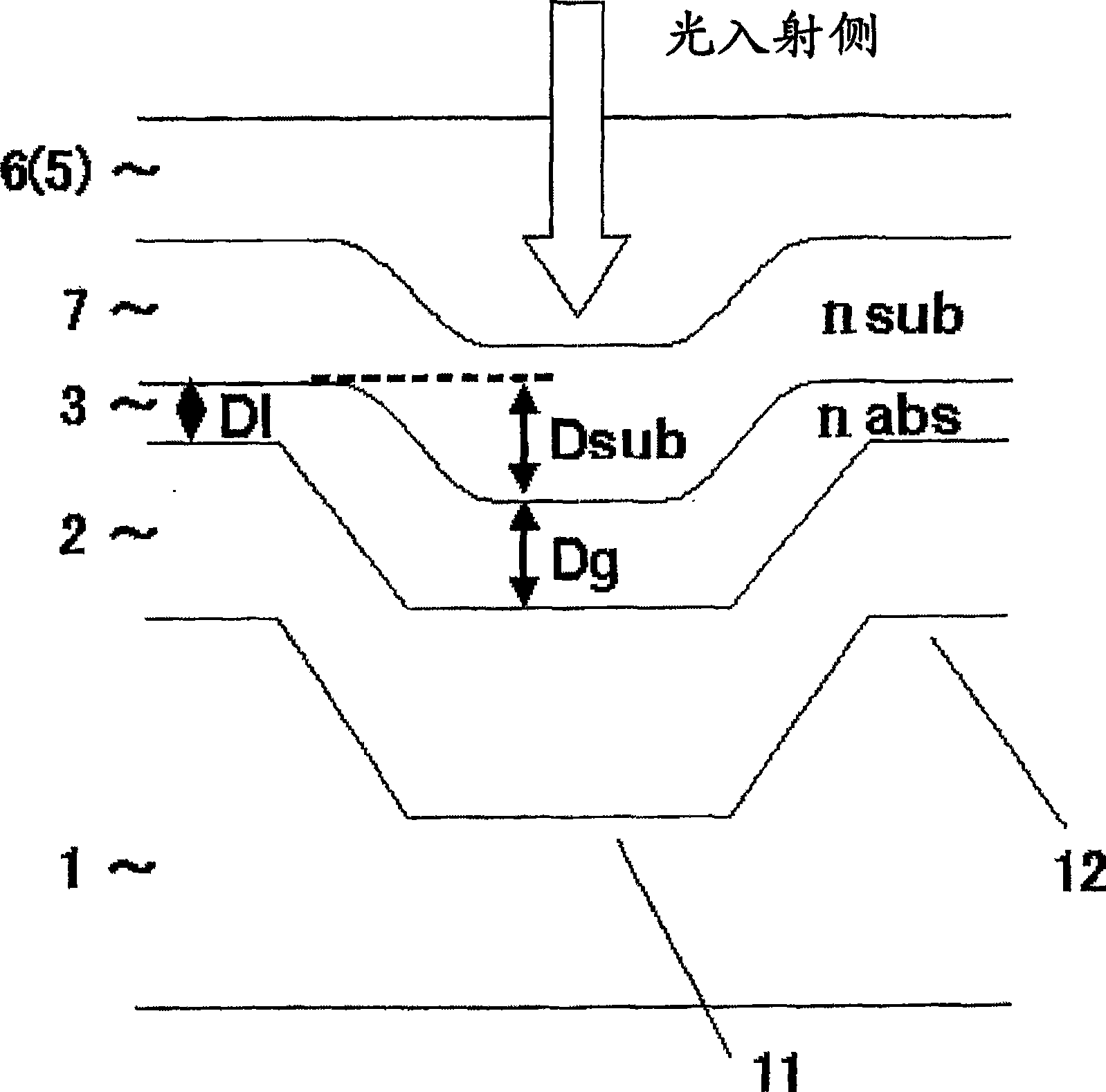

[0137] Grooves with a pitch of 0.32 μm were formed, and a disc-shaped polycarbonate substrate with an outer diameter of 120 mm and a thickness of 1.1 mm was produced. A reflective layer made of Ag alloy was sputtered on this substrate to form a channel with a depth of 45 nm and a width of 110 nm. Then, a pigment solution in which the azo pigment shown in (Chemical Formula 1) was dissolved in a TFP (tetrafluoropropanol) solvent was applied by spin coating, and dried at 80° C. for 30 minutes to form grooves. A recording layer with a film thickness of 35nm and a parting mask thickness of 15nm. Then, sputtering was performed so that the transparent intermediate layer made of aluminum nitride material had a thickness of 30 nm. Then, an optical information recording medium was obtained by bonding a light-transmitting layer made of a 0.1 mm polycarbonate sheet to the surface of the intermediate layer via a transparent adhesive.

[0138] The refractive index n and the extinction coe...

Embodiment 2

[0141] In addition to sputtering the reflective layer on the substrate to form a channel with a depth of 57nm and a width of 110nm, as a recording layer, the azo pigment shown in (Chemical formula 1) and the cyanine pigment shown in (Chemical formula 2) will be dissolved in TFP ( The pigment solution in the tetrafluoropropanol) solvent is applied by the spin coating method, and the maximum film thickness of the groove is 34nm, and the thickness of the parting film is 10nm. Except for the recording layer, it is made the same as the above-mentioned embodiment 1. Thus, an optical information recording medium was obtained.

[0142] The refractive index n and the extinction coefficient k of the recording layer of the optical information recording medium thus obtained were measured with an n, k measuring device (ETA-RT / UV manufactured by Steage ETA-Optik GmbH), and as a result, n was 1.41 , k is 0.35. In addition, the optical phase difference ΔS is 0.49, and the change amount Δk of...

Embodiment 3

[0145] In addition to sputtering the reflective layer on the substrate, a channel with a depth of 35nm and a width of 85nm was formed. As a recording layer, the same pigment solution as in Example 1 was applied by spin-coating, and a groove-maximum film was formed. Except for the recording layer having a thickness of 23 nm and a parting film thickness of 16 nm, an optical information recording medium was obtained in the same manner as in Example 1 above.

[0146]The refractive index n and the extinction coefficient k of the recording layer of the optical information recording medium obtained in this way were measured with an n, k measuring device (ETA-RT / UV manufactured by Steage ETA-Optik GmbH). As a result, n was 1.42 , k is 0.39. In addition, the optical phase difference ΔS is 0.34, and the change amount Δk of the extinction coefficient k is 0.26 when the recording layer is heated using a differential thermal analyzer (TG-DTA), and the extinction coefficient after heating i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com