Method for controlling discharge of dioxin in incineration process of domestic garbage by sulfur composition in coal

A technology for domestic waste incineration and municipal solid waste, which is applied in combustion methods, incinerators, combustion types, etc., can solve the problems of high price, small processing capacity, and small processing flue gas volume, and achieve equipment investment and operating costs. Low, simple process and system, efficient incineration and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

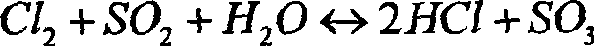

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

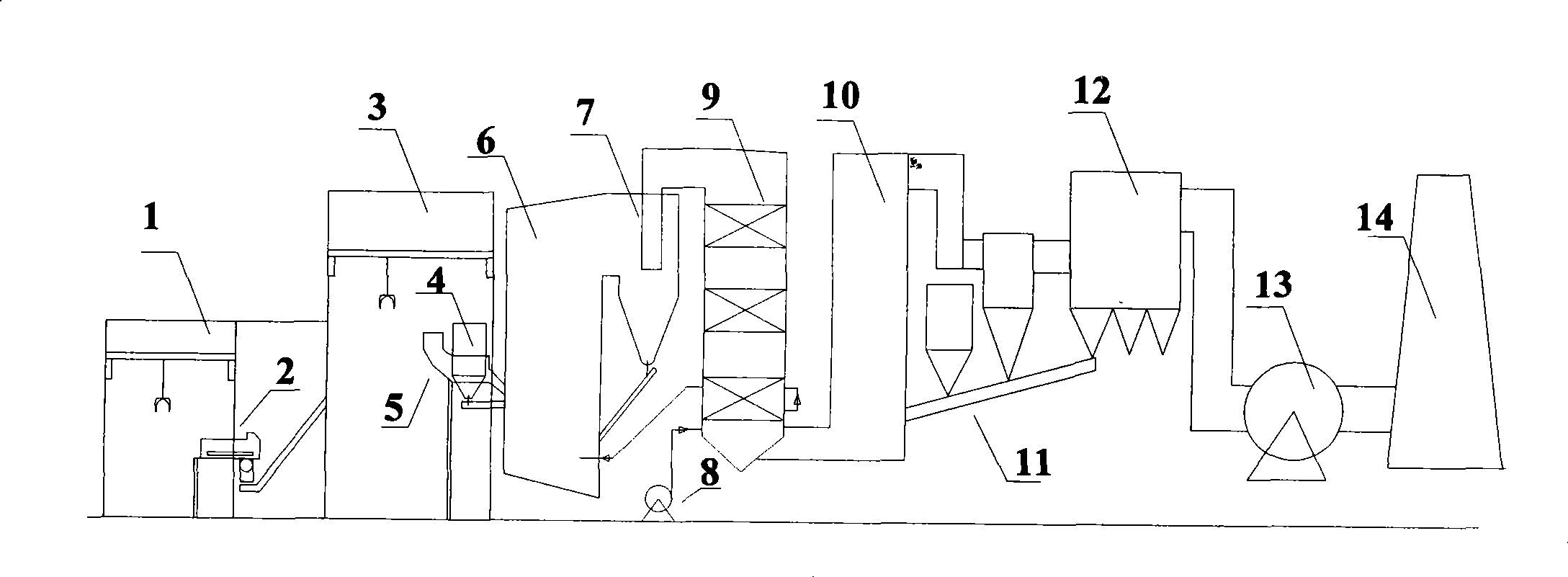

[0023] With reference to the drawings, the present invention will be described in detail below.

[0024] The method of using sulfur in coal to control dioxin emission during the incineration of domestic waste in this embodiment includes the following steps:

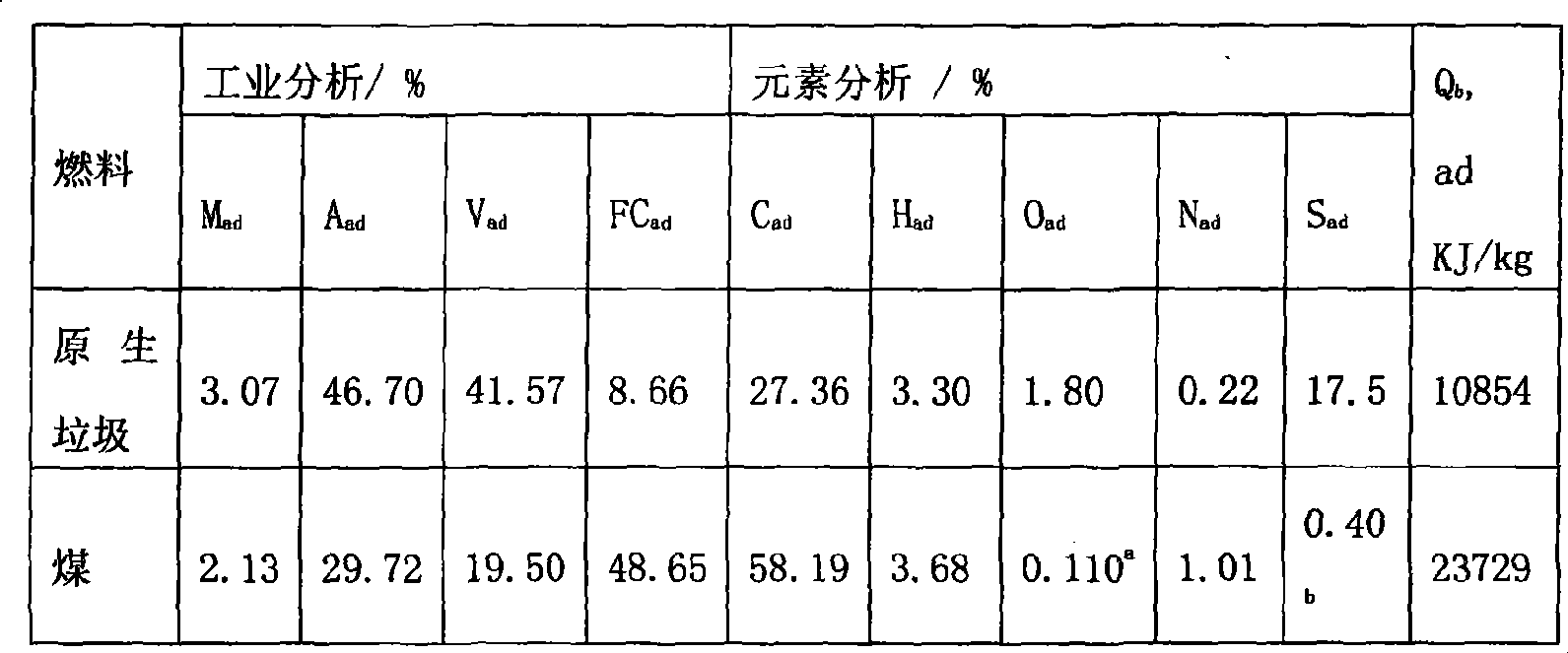

[0025] (1) Put the coal and municipal solid waste into a fluidized bed incinerator after mixing, and control the amount of coal added according to the calorific value of the municipal solid waste. The amount of coal added is less than 20% of the total weight of the mixture;

[0026] (2) The flue gas and entrained particulate matter generated during combustion in the incinerator are separated by a high-temperature cyclone; the particulate matter is returned to the incinerator, and the flue gas enters the semi-dry flue gas purification device after passing through the waste heat recovery device;

[0027] (3) The flue gas passes through the bag filter to remove the fly ash particles, and then is discharged into the chimney throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com