Composite passivated reflection reducing membrane for crystalline silicon solar cell and preparation thereof

A crystalline silicon solar cell and solar cell technology, applied in the field of solar cells, can solve the problems of performance deterioration, no advantage, poor quality of silicon wafers, etc., and achieve excellent passivation, simple and feasible preparation process, and good anti-reflection effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

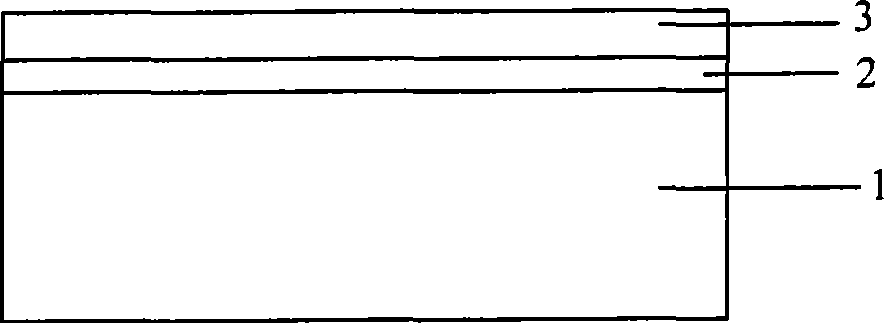

[0015] An amorphous silicon / titanium dioxide composite passivation anti-reflection film, wherein the thickness of the amorphous silicon layer directly deposited on the light-facing surface of the solar cell to play a passivation role is 25 nanometers, and the amorphous silicon layer is deposited on the The thickness of the anti-reflection titanium dioxide layer is 80 nanometers.

Embodiment 2

[0017] A method for preparing an amorphous silicon / titanium dioxide composite passivation anti-reflection film, comprising: adopting a chemical vapor deposition (PECVD) process to deposit and prepare a 5-nanometer thick amorphous silicon layer on a solar cell, and then depositing a 5-nanometer thick amorphous silicon layer on the amorphous silicon A 90nm-thick titanium dioxide layer is deposited on the crystalline silicon layer by using an atmospheric pressure chemical vapor deposition (APCVD) process.

Embodiment 3

[0019] A method for preparing an amorphous silicon / titanium dioxide composite passivation anti-reflection film, comprising: adopting a chemical vapor deposition (PECVD) process to deposit and prepare a 50-nanometer thick amorphous silicon layer on a solar cell, and then depositing a 50-nanometer thick amorphous silicon layer on the amorphous silicon A 70nm-thick titanium dioxide layer is deposited on the crystalline silicon layer by a thermal spraying process.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com