Catalyst for directly preparing dimethyl ether using carbon dioxide and use method thereof

A carbon dioxide and catalyst technology, which is applied in the field of catalysts for the preparation of dimethyl ether, can solve the problems of low conversion rate of carbon dioxide and poor selectivity of dimethyl ether, etc., and achieve the effect of overcoming the low conversion rate of carbon dioxide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

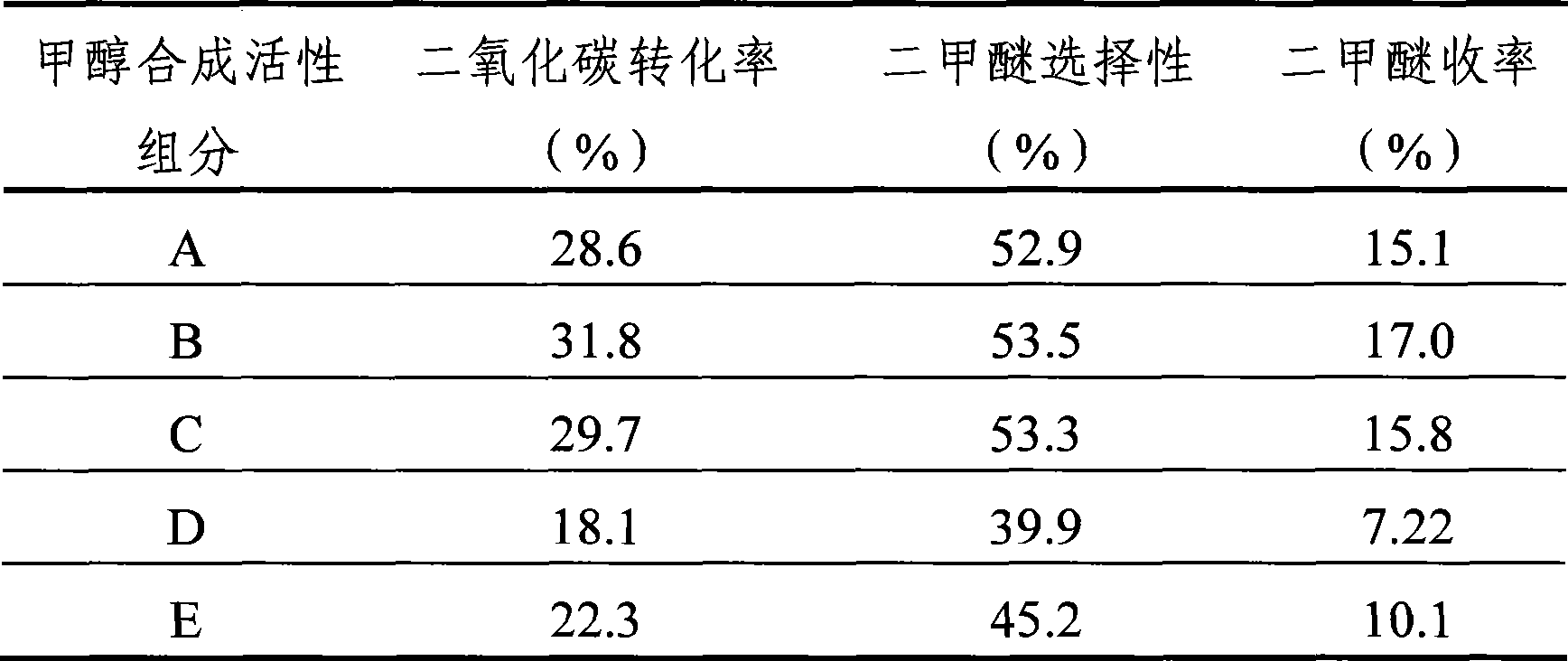

[0021] Dissolve 12.2 grams of copper nitrate, 7.3 grams of zinc nitrate, 7.0 grams of zirconium nitrate and 4.6 grams of titanium tetrachloride in 200 milliliters of distilled water to make a mixed solution, and add sodium carbonate with a concentration of 1 mol / L to the above mixed solution under stirring The solution was precipitated, and the obtained sediment was aged at room temperature for 1 hour, then filtered, dried, and then calcined at 350° C. for 6 hours to obtain catalyst powder. Finally, tablet, pulverize and sieve 20-40 mesh particles to obtain methanol synthesis active component A, wherein the weight percentage of each component is CuO 40%, ZnO 20%, TiO 2 20%, ZrO 2 20%.

Embodiment 2

[0023] Adopt the method identical with embodiment 1 to make CuO-ZnO-TiO 2 -ZrO 2 Methanol synthesis active component B, wherein the weight percentage of each component is CuO 40%, ZnO 2 30%, TiO 2 10%, ZrO 2 20%.

Embodiment 3

[0025] Adopt the method identical with embodiment 1 to make CuO-ZnO-TiO 2 -ZrO 2 Methanol synthesis active component C, wherein the weight percentage of each component is CuO 50%, ZnO 20%, TiO 2 10%, ZrO 2 20%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com