Organic nonmetal catalyst for preparing poly(p-dioxanone)

A polydioxanone and non-metallic catalyst technology, applied in the field of organic non-metallic catalysts, can solve the problems of long reaction time, wide distribution of polymeric materials, low conversion rate, etc., and achieves high molecular weight, narrow distribution and high activity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

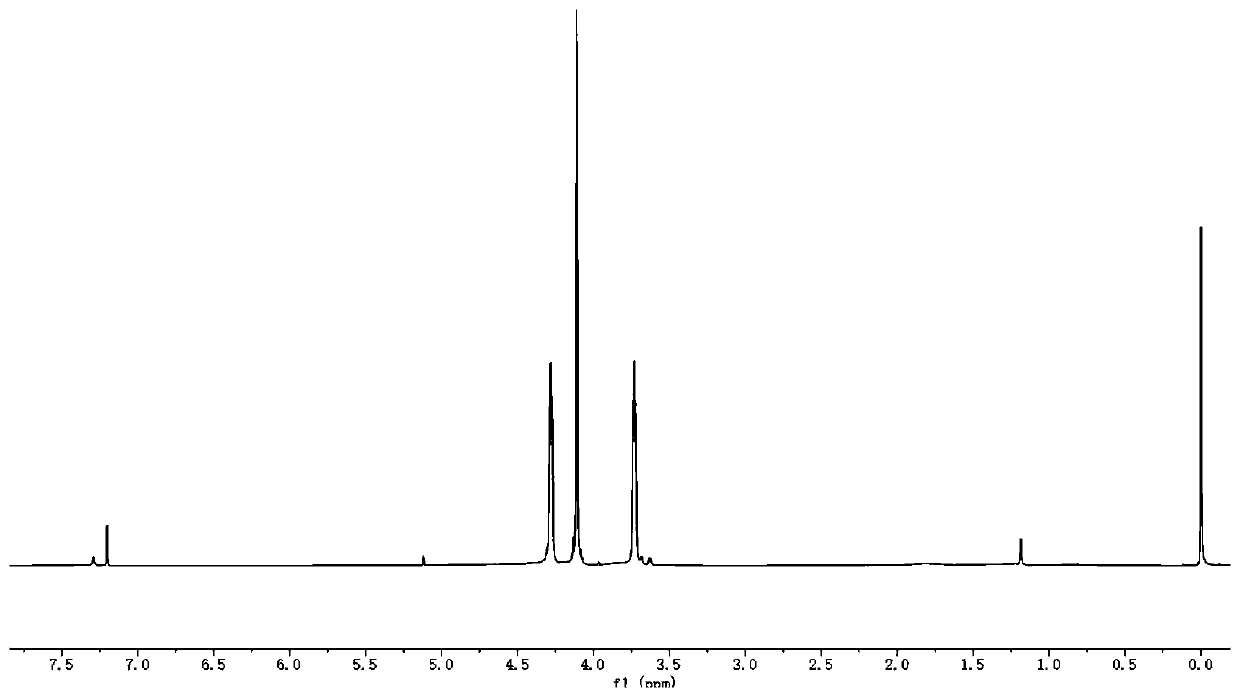

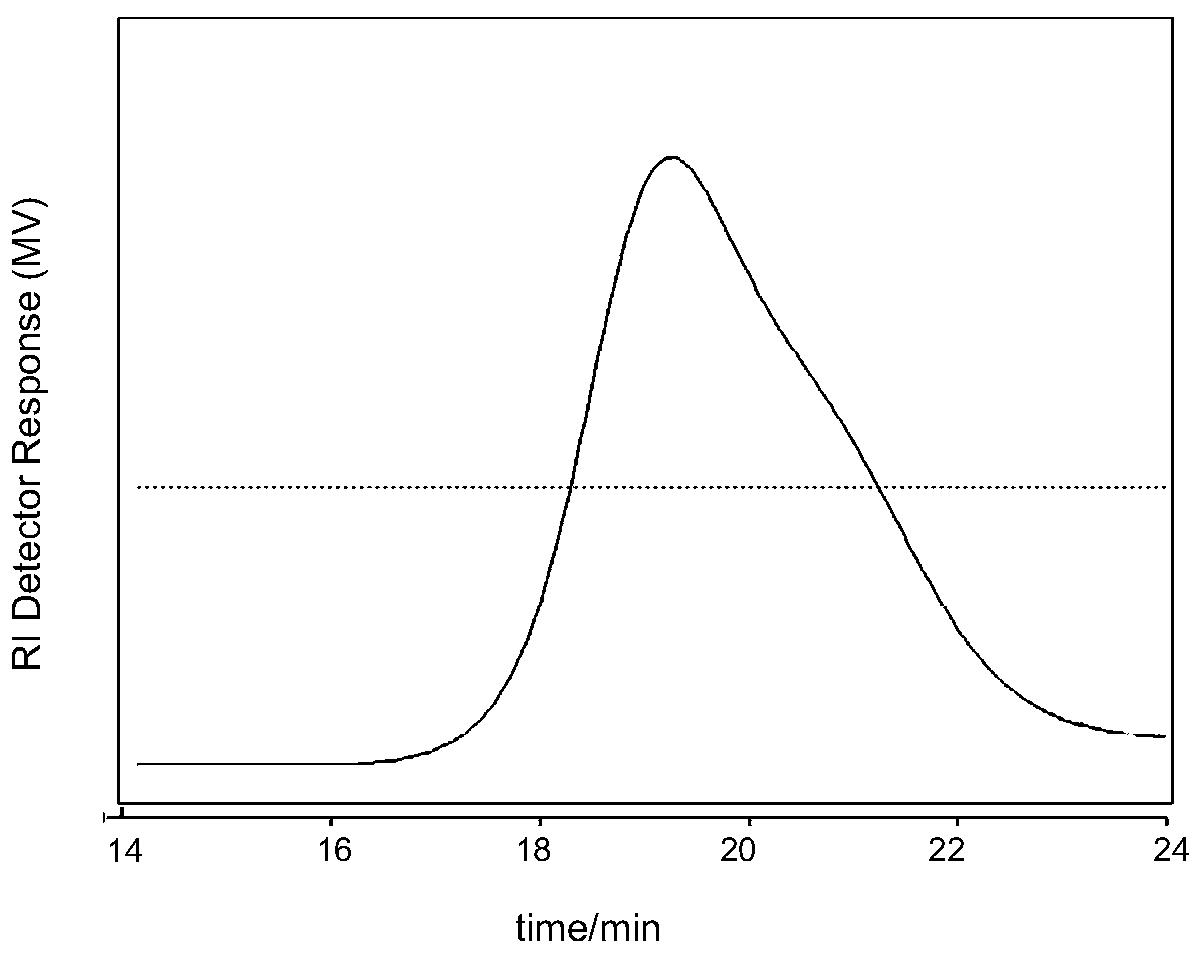

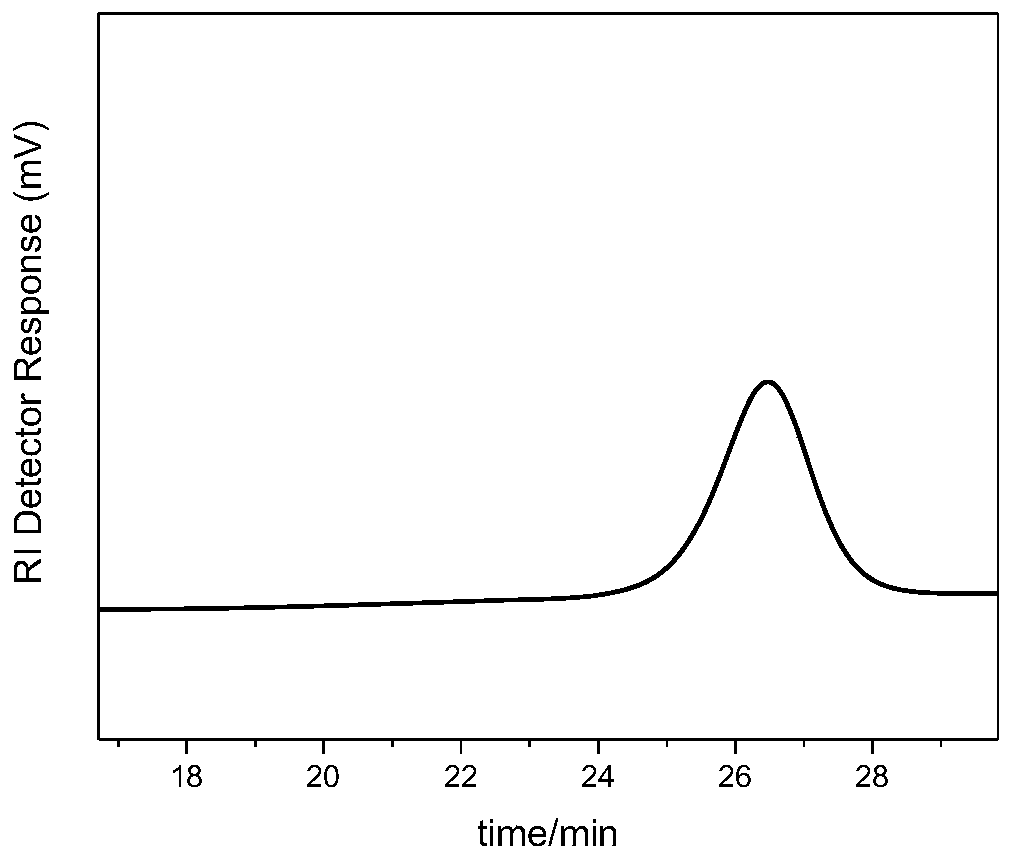

[0036] The operation process was carried out in an anhydrous and oxygen-free environment in a glove box. In a glass reaction bottle with an effective volume of 25mL, organic non-metallic catalyst 1 (0.0250g, 0.05mmol), benzyl alcohol (0.0060g, 0.05mmol) was added, and then PDO (1.02g, 10mmol), 1mL toluene, react at 25°C for 4 hours. When the system is completely solidified, quench it by adding benzoic acid, add hot chloroform to dissolve the product, and take a sample for use 1 H NMR can obtain the conversion rate of the monomer, and the white powdery PPDO polymer can be obtained by precipitation in methanol. The catalytic results are shown in Table 1, and the nuclear magnetic spectrum and gel permeation chromatogram are shown in figure 1 and figure 2 (The abscissa is time, and the ordinate is the detector signal).

Embodiment 2

[0038] As shown in Example 1, under the same conditions, the organic non-metallic catalyst 2 was used, and after 4 hours of reaction, a PPDO polymer was obtained. The catalytic results are shown in Table 1.

Embodiment 3

[0040] As shown in Example 1, under the same conditions, the organic non-metallic catalyst 3 was used, and after 1 hour of reaction, a PPDO polymer was obtained. The catalytic results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com