High efficiency separation and purification method of camptothecine

A technology for separation and purification of camptothecin, which is applied in the fields of organic chemistry, pharmaceutical formulations, and medical preparations containing active ingredients, etc. It can solve the problems of hidden dangers of product safety, difficult removal of impurities, increase of production costs, etc. High efficiency, good extraction effect and small sewage discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

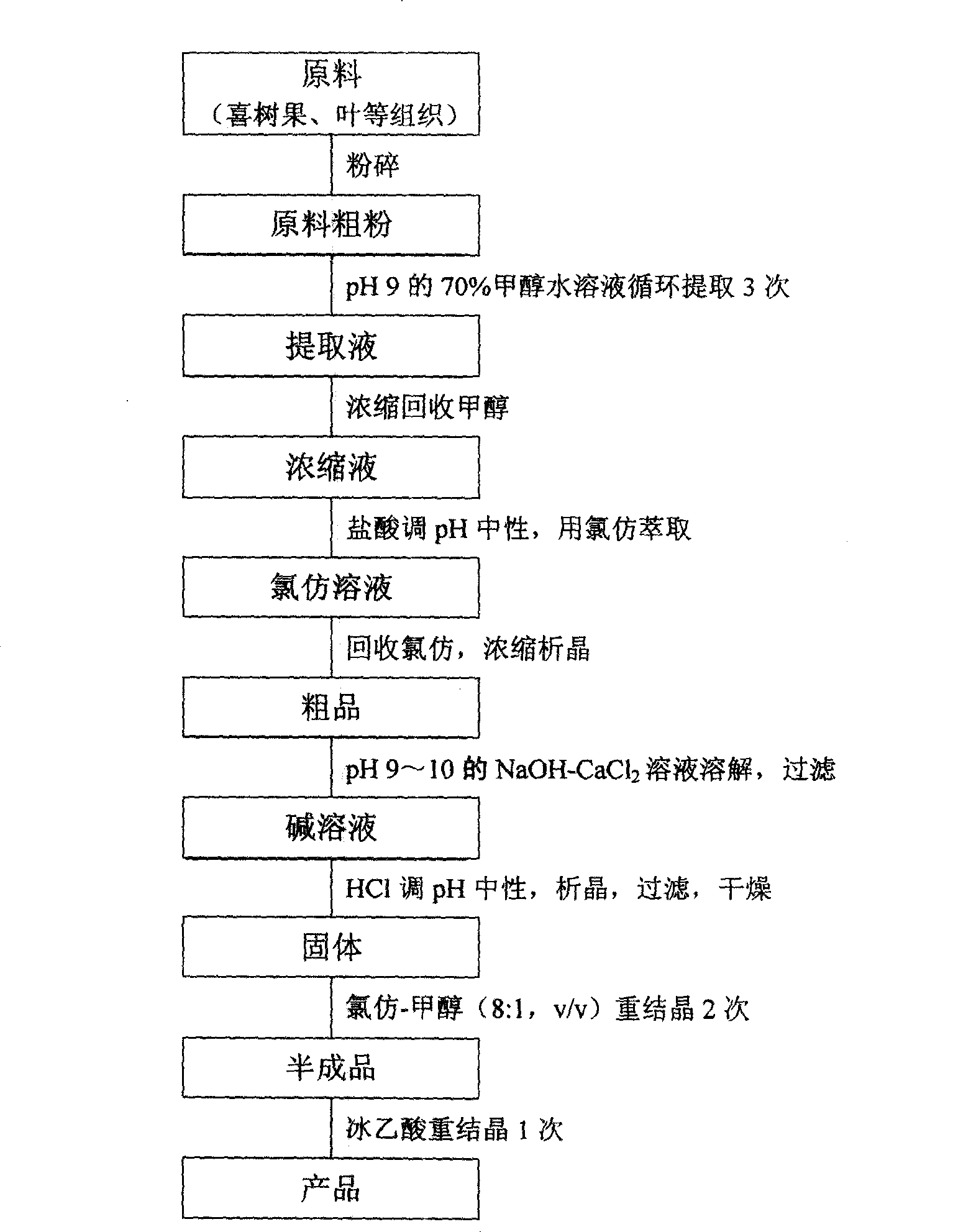

[0027] A high-efficiency separation and purification method for camptothecin, characterized in that it is carried out according to the following process steps:

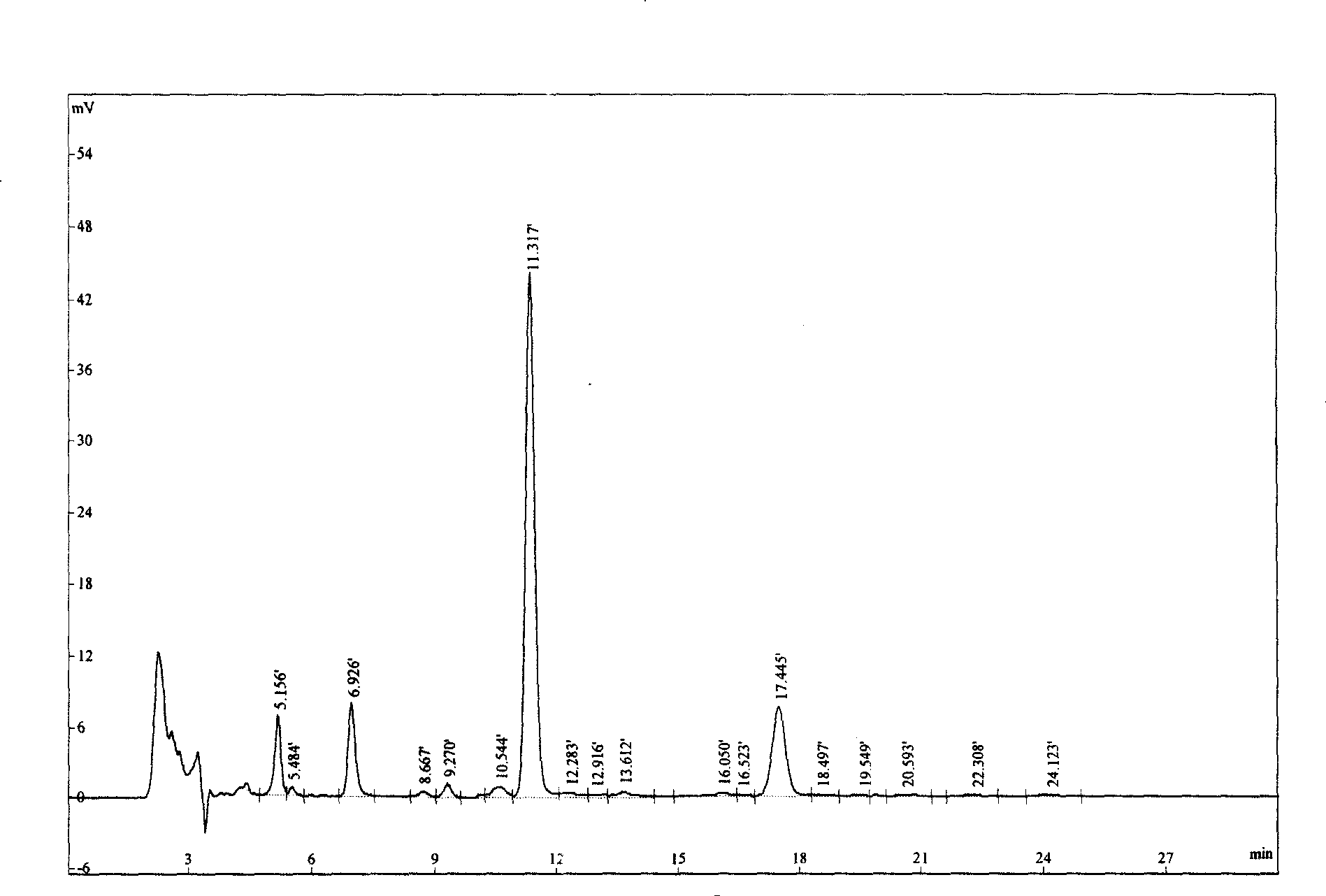

[0028] A. Extraction of camptothecin crude product: crush 3000kg camptothecin fruit into coarse powder, and put it into a volume of 6m 3 In the extraction tank, the aqueous methanol solution with a pH value of 9 and a concentration of 70% by volume was used for cyclic extraction for 3 times. For the first time, 8000L of solvent was added, and the extraction time was 8 hours; for the second time, 7000L of solvent was added, and the extraction time was 6 hours; for the third time, 6000L of solvent was added, and the extraction time was 4 hours. The extracts were combined and single-effect concentrated at 70°C to recover methanol. Concentrated hydrochloric acid was added to the concentrated solution to adjust the pH value to neutrality, and then extracted three times with 2000L chloroform, the chloroform phase was conce...

Embodiment 2

[0033] A method for separating and purifying camptothecin, characterized in that it is carried out according to the following processing steps:

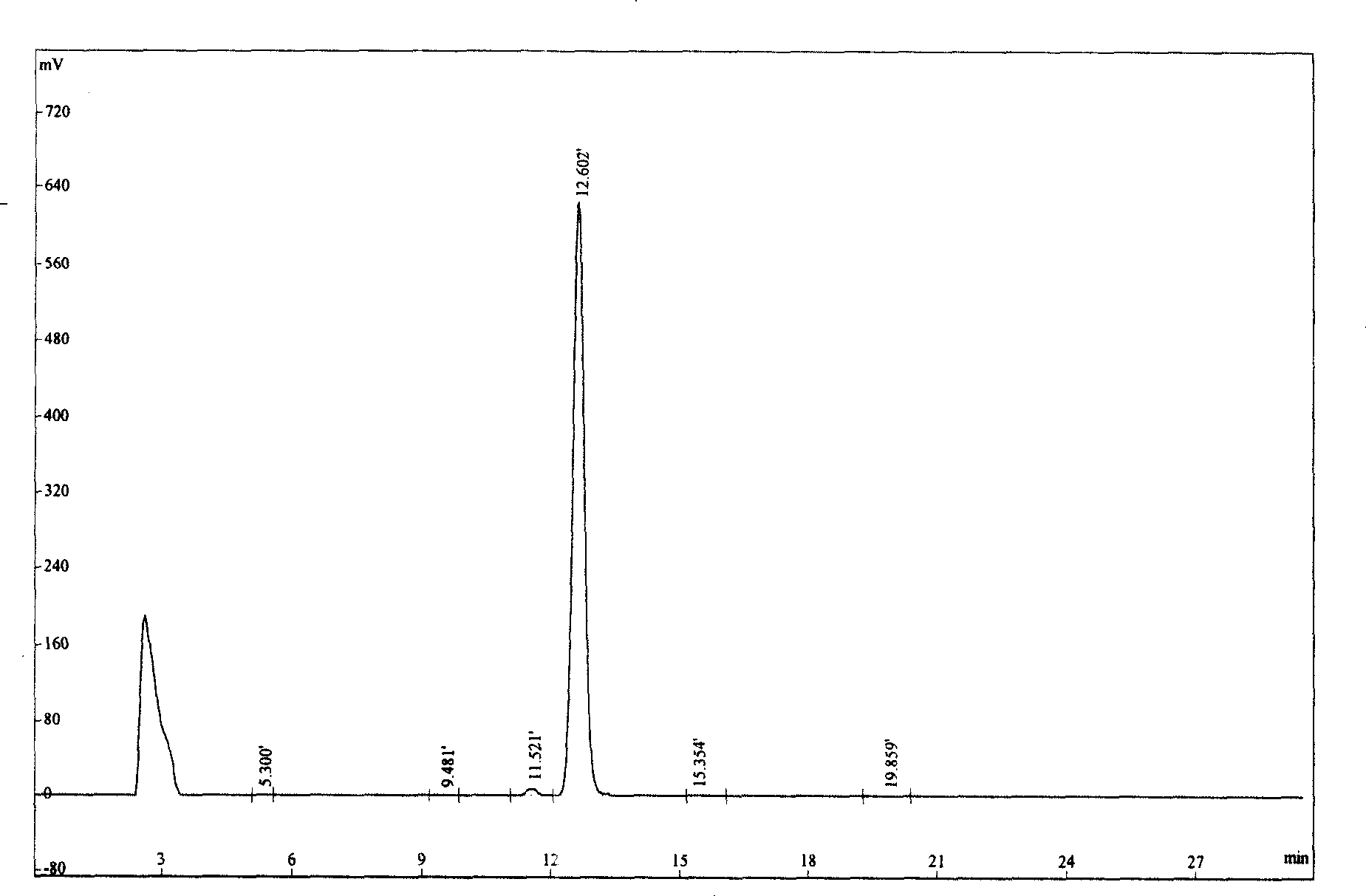

[0034] A. Extraction of camptothecin crude product: crush 3000kg camptothecin leaves into coarse powder, and put it into a volume of 6m 3 In the extraction tank, use 80% sodium hydroxide solution to adjust the pH value to 9, and the methanol aqueous solution whose volume ratio concentration is 70% is cyclically extracted for 3 times. For the first time, 8000L of solvent was added, and the extraction time was 8 hours; for the second time, 7000L of solvent was added, and the extraction time was 6 hours; for the third time, 6000L of solvent was added, and the extraction time was 4 hours. The extracts were combined and single-effect concentrated at 70°C to recover methanol. Concentrated hydrochloric acid was added to the concentrated solution to adjust the pH value to neutrality, and then extracted three times with 2000L chloroform, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com