On-line measurement method and device for micro/nano deep trench structure

A measurement method and deep trench technology, which are applied in measurement devices, optical devices, semiconductor/solid-state device testing/measurement, etc., can solve the problems of precision installation, debugging and calibration, and the inability to meet the requirements of rapid extraction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

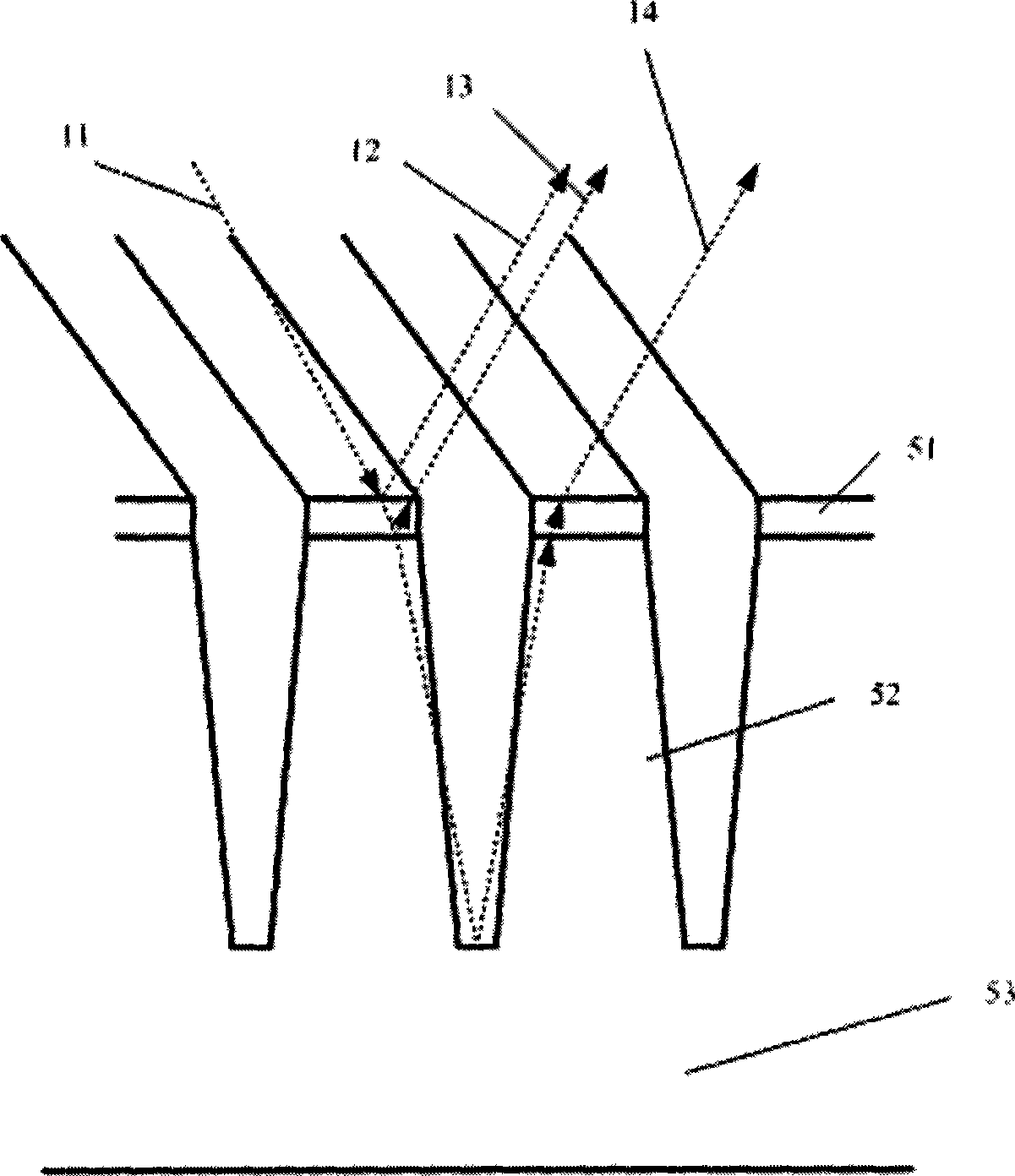

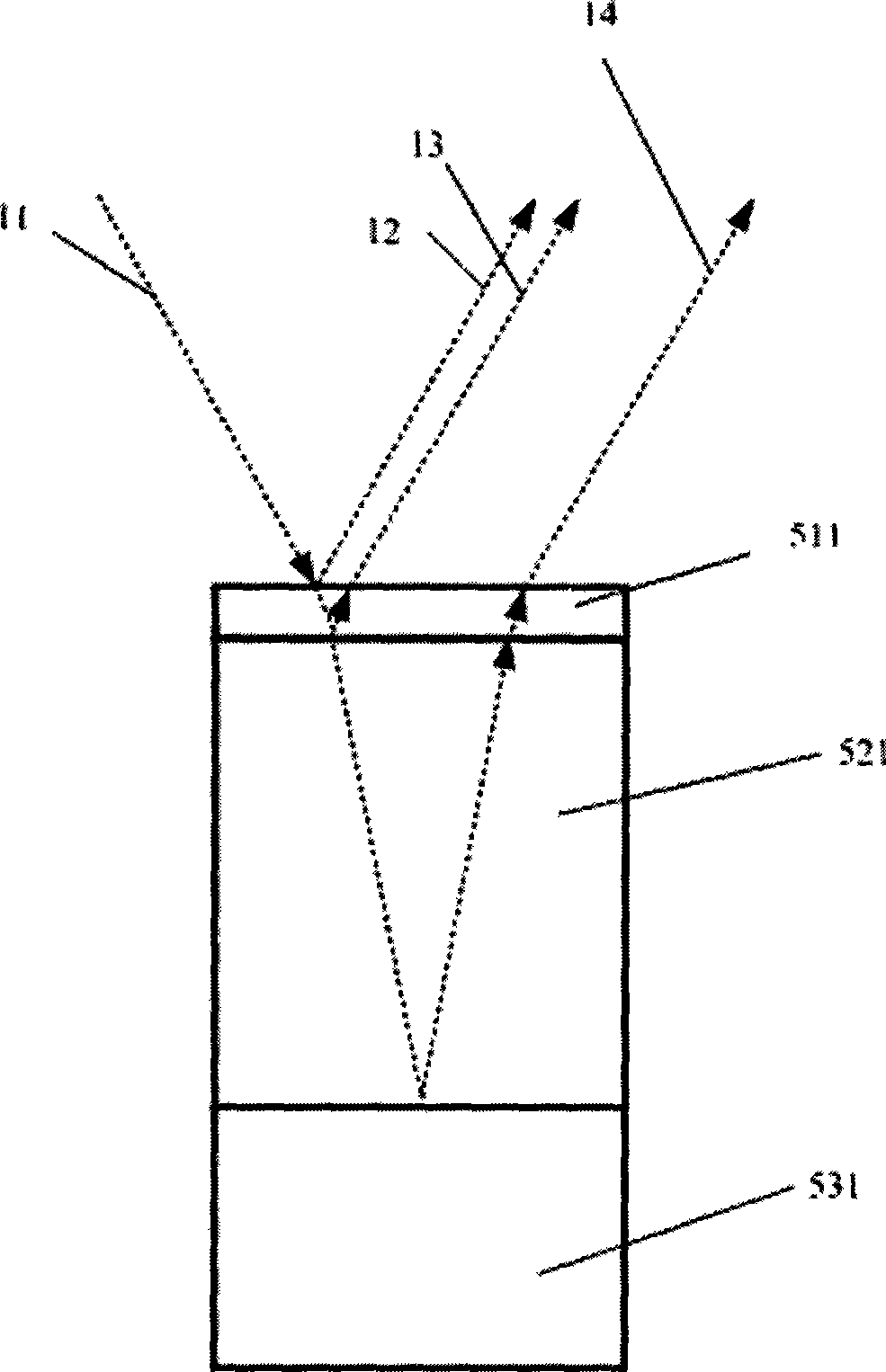

[0034] Taking the measurement process of the inclined wall deep groove structure as an example, the principle and working process of the method of the present invention will be further described in detail in conjunction with the accompanying drawings:

[0035] (1) Project the infrared beam onto the surface of the object to be tested that contains the deep groove structure, the wavelength of the infrared beam is in the mid-infrared wavelength range, and the wavelength is 2-20um;

[0036] (2) After the incident light beam is reflected by each surface of the groove structure, an infrared detector is used to receive each reflected signal, and an interference signal containing the geometric information of the groove is obtained;

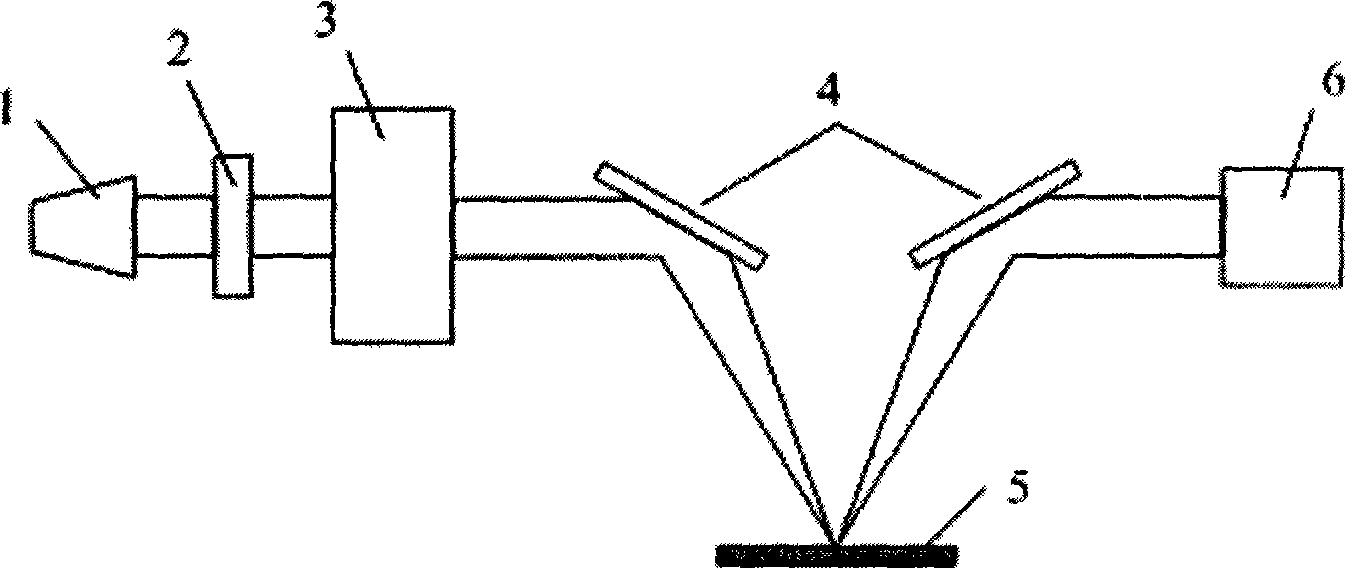

[0037] Such as figure 1 As shown, the infrared beam emitted by the infrared light source 1 is polarized by the infrared polarizer 2 to obtain linearly polarized light, and the linearly polarized light enters the interferometer 3, modulated by the interfer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com