Method for measuring fragrance quality of tobacco and products thereof

A method of determination and technology of aroma substances, applied in the field of determination of tobacco quality, to achieve the effect of simplifying the calculation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

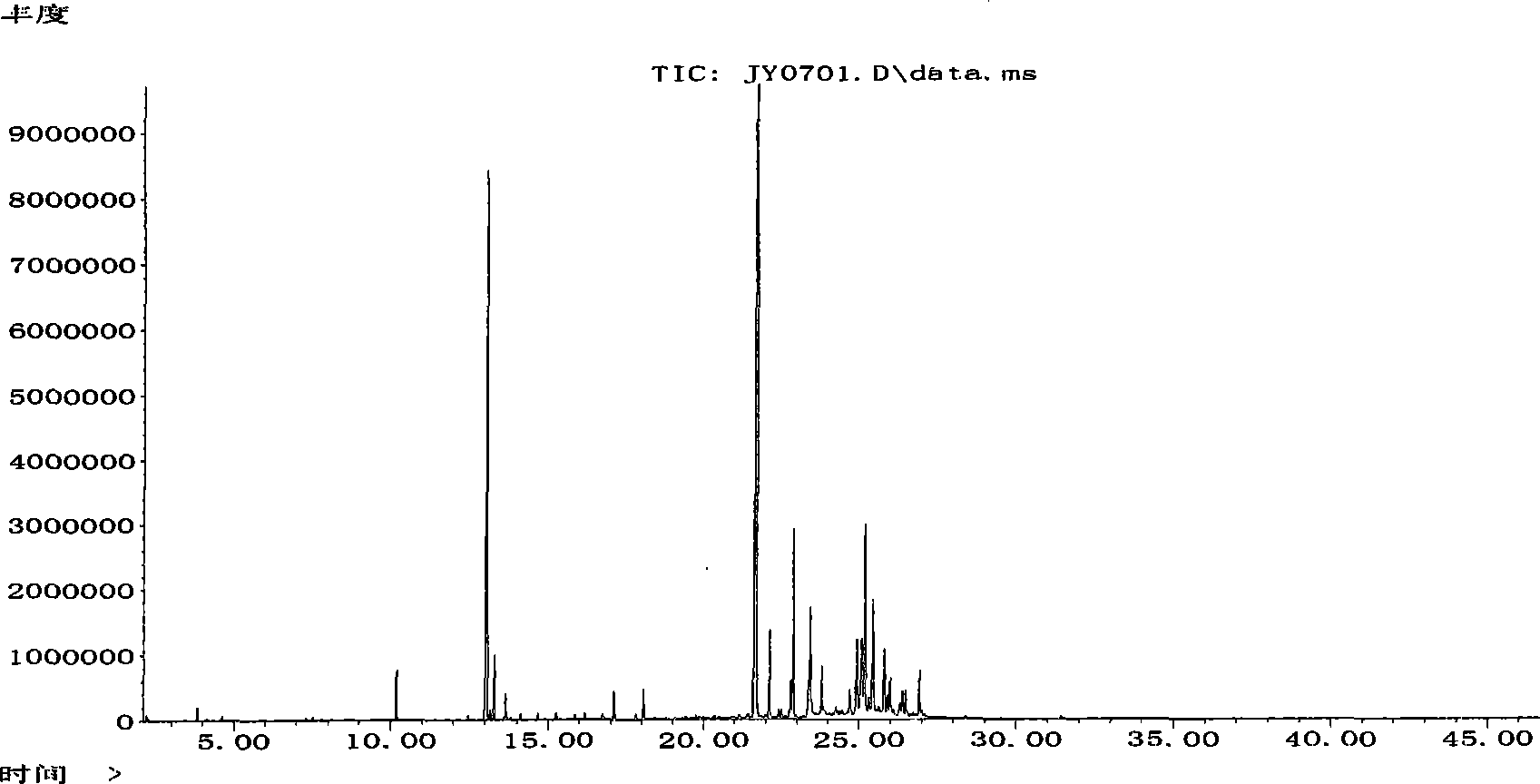

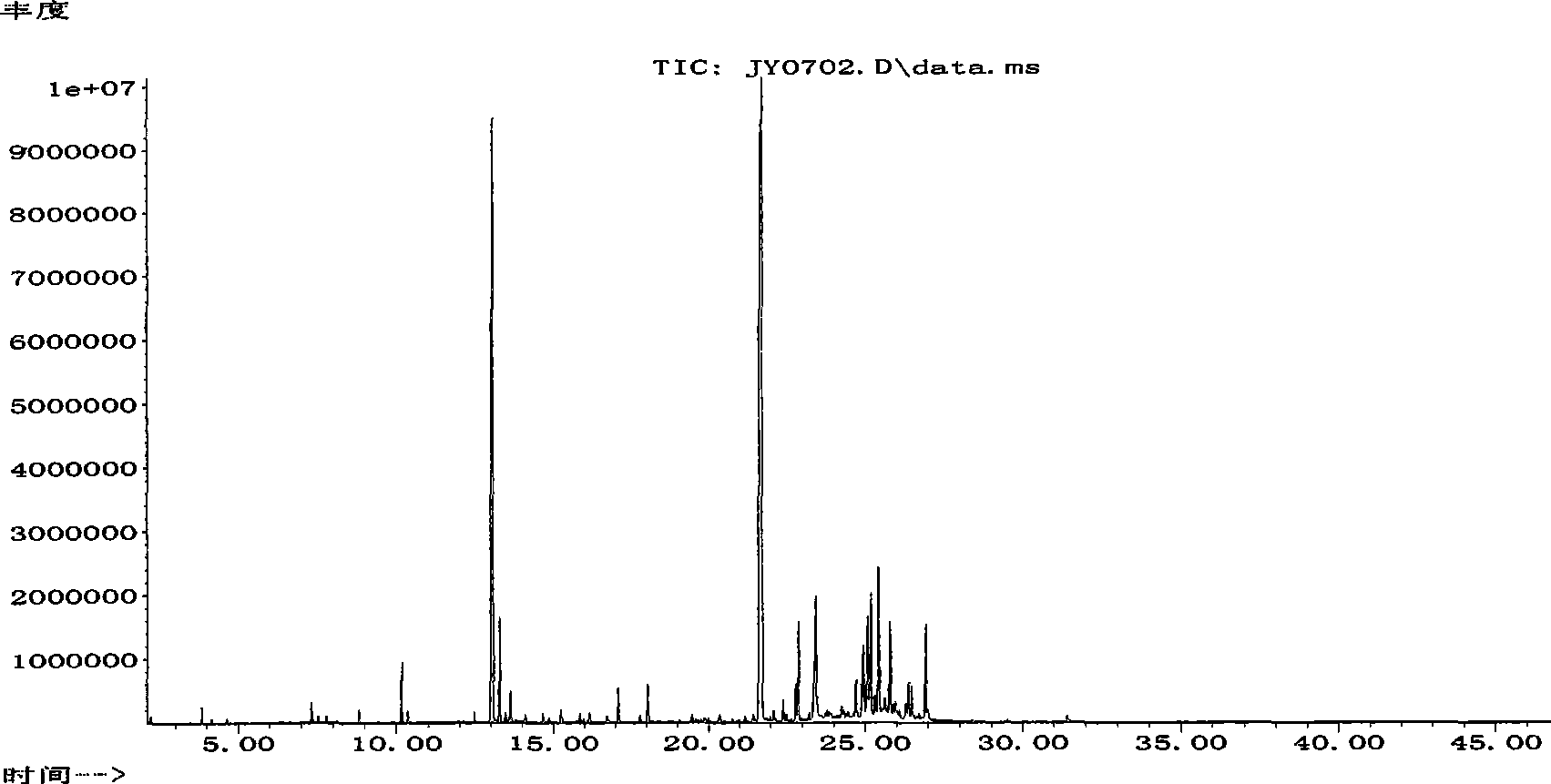

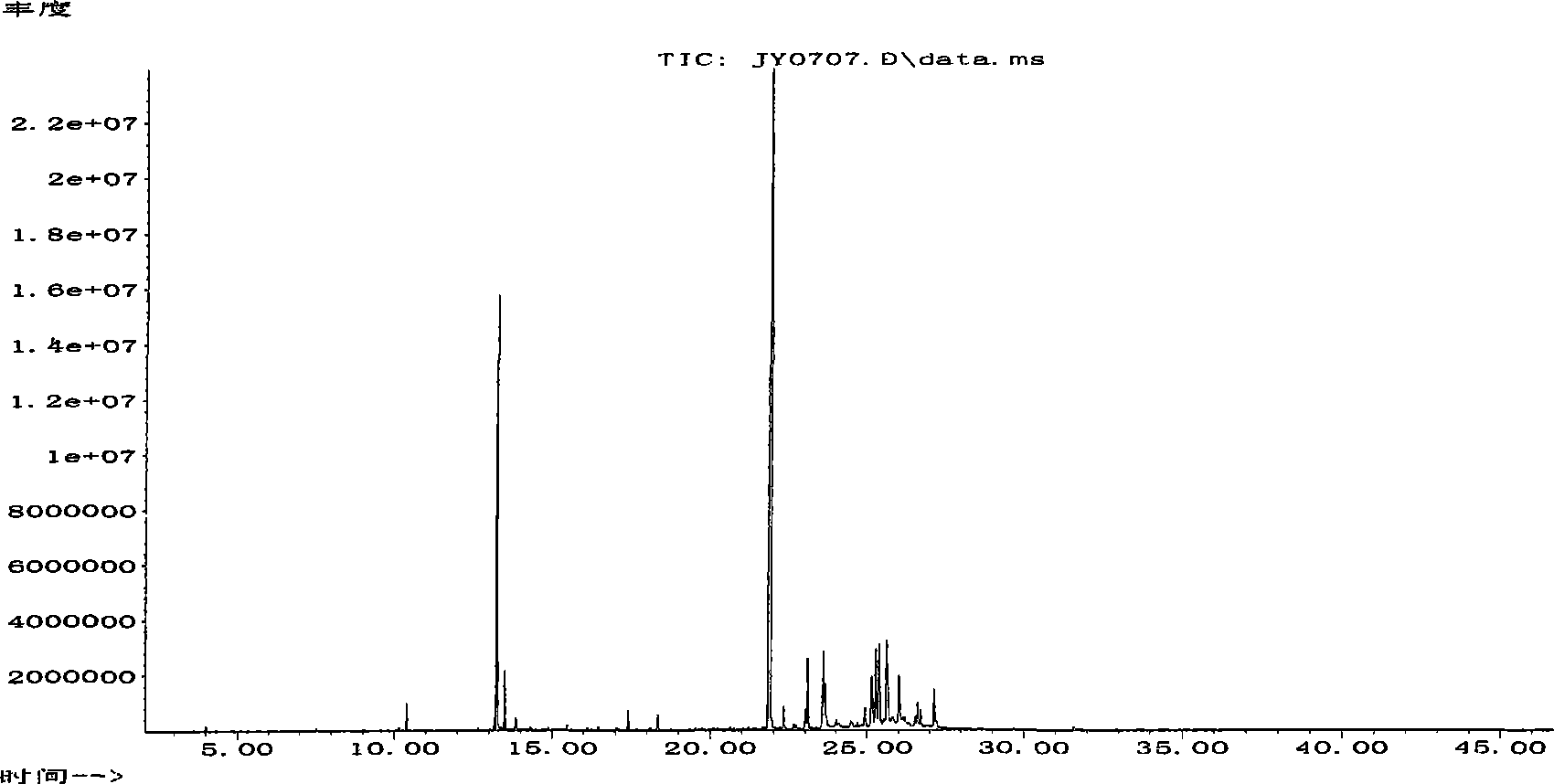

Image

Examples

Embodiment 1

[0025] ——Sample processing process

[0026] After roasting the shredded tobacco at (40±1)°C for 4 hours, crush it with a pulverizer, pass through a 40-mesh sieve, and balance the obtained tobacco powder in a balance box at a temperature of 22°C and a humidity of 60% for 24 hours. 25.0 g of tobacco powder samples were put into a simultaneous distillation and extraction device, and dichloromethane was used as a solvent to continuously and dynamically extract tobacco shreds for 2 hours. After the obtained extract was dried over anhydrous sodium sulfate, it was concentrated to 1.0 mL in a rotary evaporator. Add 50 μl, 0.1mol / L benzyl acetate solution in absolute ethanol, shake well, and analyze it with Agilent 6890N / 5973N GC / MS analyzer.

[0027] Instruments and experimental conditions used:

[0028] Reagents: dichloromethane (AR, Xilong Chemical), anhydrous sodium sulfate (AR, Tianjin Kemiou Company), absolute ethanol (chromatographically pure, Dima Company), benzyl acetate (chr...

Embodiment 2

[0032] - Calculation of compound content

[0033] Calculate the relative content of each substance by formula 1:

[0034] Ce = β × Cr × At Ar - - - ( 1 )

[0035] In the formula, Ce—the relative correction content of the target component; β—the correction coefficient, the value is 7.2; Cr—the content of the internal standard; At—the peak area of the target component; Ar—the peak area of the internal standard.

Embodiment 3

[0037] ——Compilation of KR index

[0038] Bring the value calculated by formula 1 into formula 2, and the obtained value is the KR value

[0039] KR value = product of positive correlation factors / product of negative correlation factors (2)

[0040] Positively correlated factors include: 3-hydroxy-2-butanone, hexanal, bread ketone, furfural, furfuryl alcohol, 2-cyclopentene-1,4-dione, 1-(2-furyl)-ethanone, butane Lactone, Benzaldehyde, 5-Methylfurfural, 6-Methyl-5-Hepten-2-one, Benzyl Alcohol, Linalool, Phenylethyl Ethanol, 2,6-Nadienal, Zanal, 2 -Methoxy-4-vinylphenol, BETA-Damascone, BETA-Dihydrodamascone, Geranylacetone, BETA-Ionone, Dihydroactinolactone, Macrostigmatrienone A, Macrobean 29 substances including trienone B, macrostigmatrienone C, macrostigmatrienone D, 3-oxo-ALPHA-ionol, methyl myristate, and naringone.

[0041] Negative correlators include: pyridine, 3-methyl-2-butenal, phenol, phenylacetaldehyde, 2-methylphenol, 2-methoxy-phenol, indole, solanone, deh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com