Novel stannic acid barium based conductive ceramics and method of manufacturing the same

A technology for conductive ceramics and conductive ceramic materials, applied in the field of conductive ceramic materials, can solve problems such as no cause, and achieve the effects of low resistivity, simple preparation process and stable chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

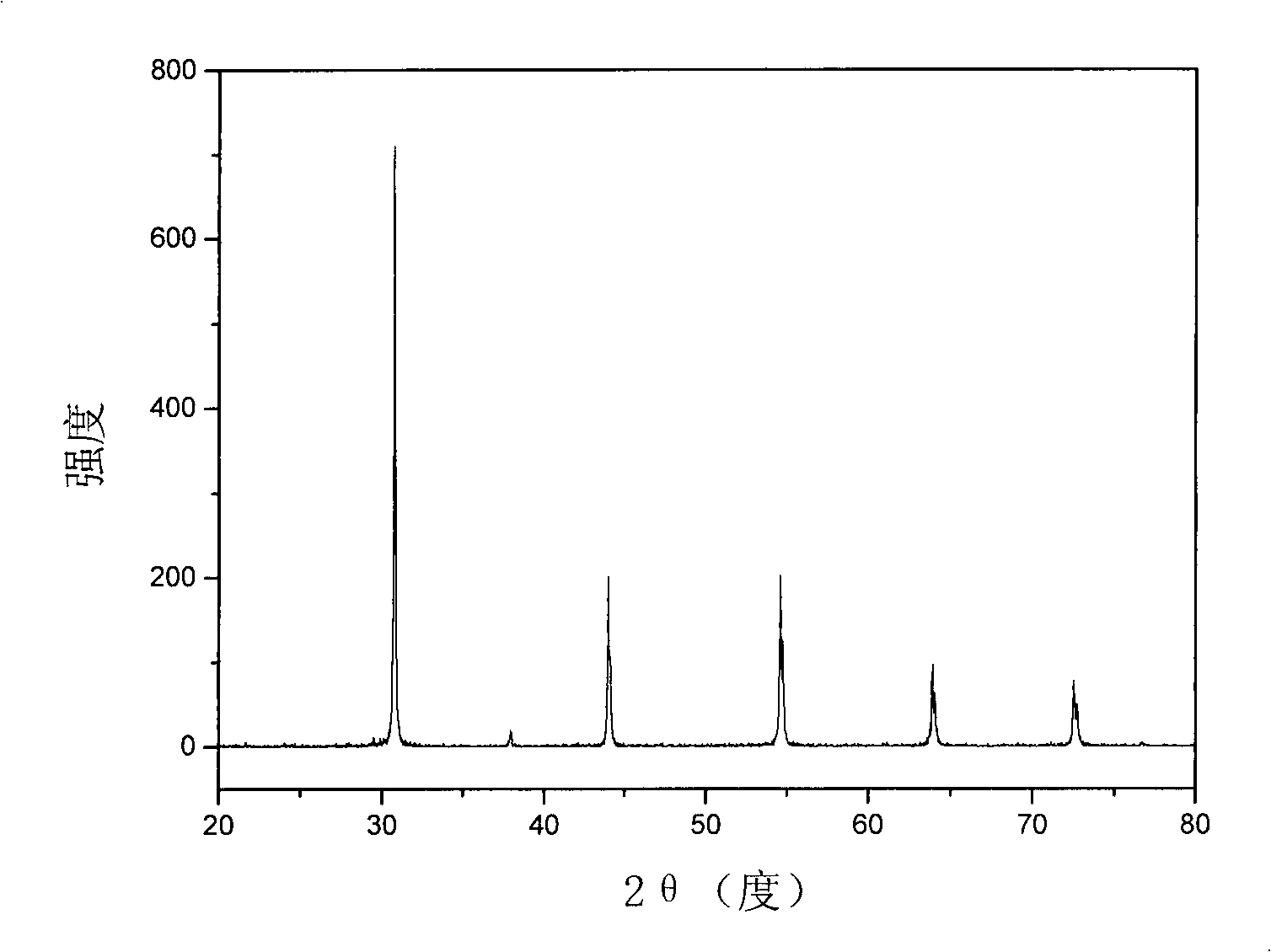

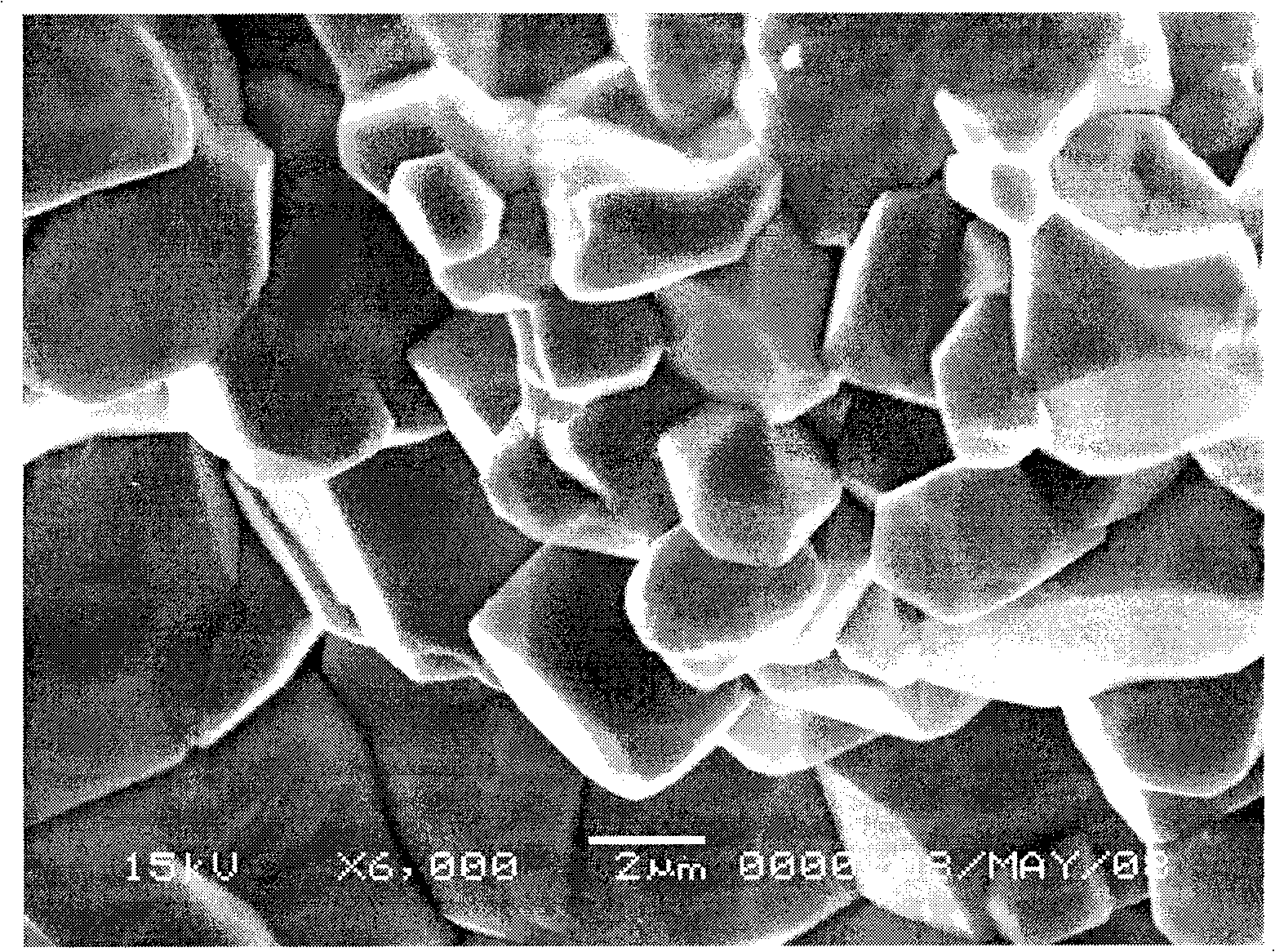

[0014] To analyze pure BaCO 3 , SnO 2 and Sb 2 o 3 Raw material, according to the chemical formula BaSb 0.06 sn 0.94 o 3 Carry out batching, wet grinding with absolute ethanol as the medium, dry at 80°C and keep warm in the air at 1300°C for 2 hours to pre-synthesize ceramic blanks; the ceramic blanks are passed through a 300-mesh sieve after secondary ball milling and drying, and then add 3% concentration of PVA solution is used as a binder, pressed into a disc with a diameter of 18mm and a thickness of 1-1.4mm under a pressure of 100MPa, and the binder is discharged at a heating rate of 150℃ / h at 600℃ for 2 hours, and then heated at 300℃ / h The heating rate is kept at 1550°C for 2 hours, and finally cooled to room temperature with the furnace; the sintered ceramic sheet is ground to 1.00±0.02mm with sandpaper, and silver electrodes are used on both sides. XRD test shows that the ceramic is a single-phase solid solution and no impurity phase is formed. SEM photos show t...

Embodiment 2

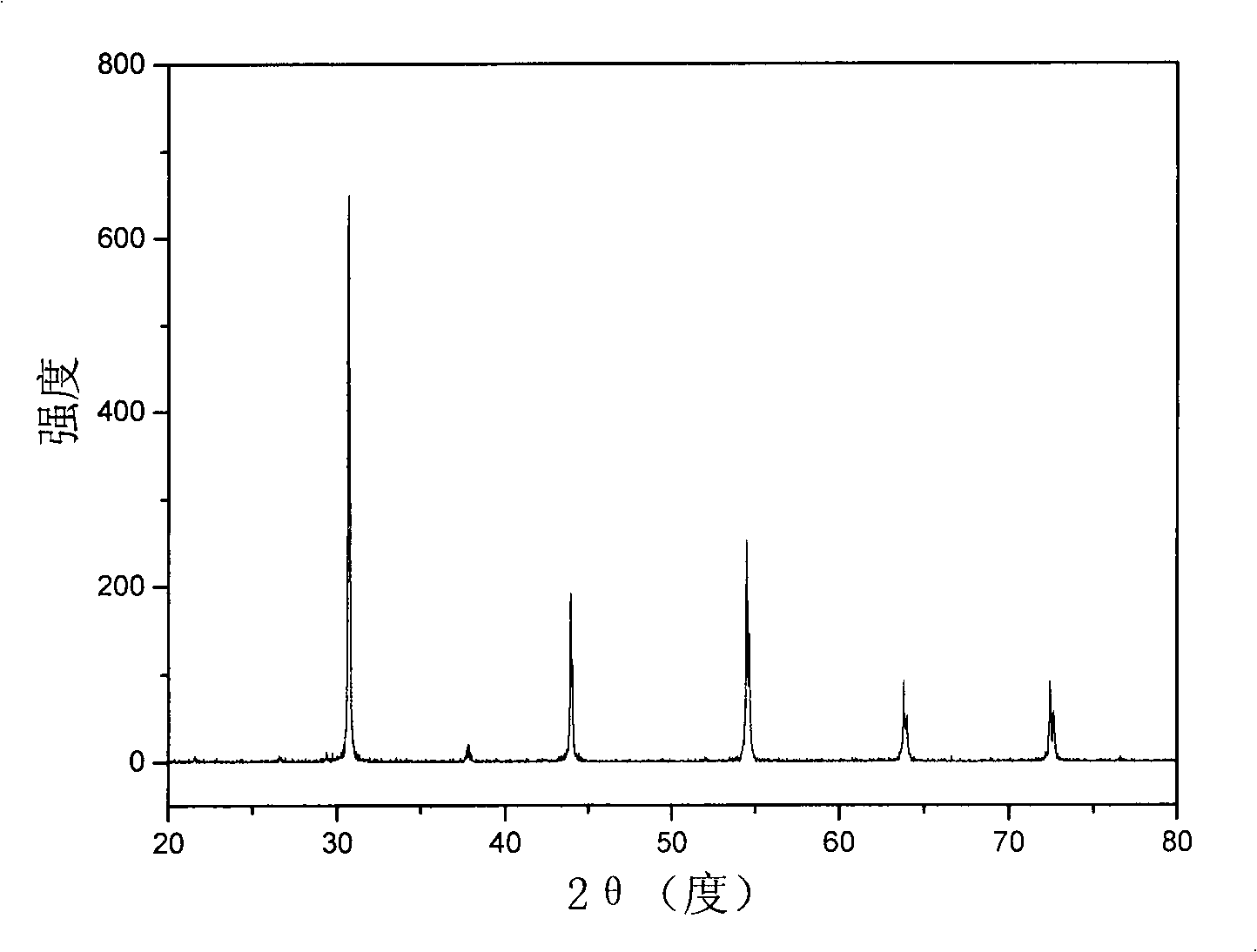

[0016] To analyze pure BaCO 3 , SnO 2 and Sb 2 o 3 Raw material, according to the chemical formula BaSb 0.1 sn 0.9 o 3 Carry out batching, wet grinding with absolute ethanol as the medium, dry at 80°C and keep warm in the air at 1300°C for 2 hours to pre-synthesize ceramic blanks; the ceramic blanks are passed through a 300-mesh sieve after secondary ball milling and drying, and then add 3% concentration of PVA solution is used as a binder, pressed into a disc with a diameter of 18mm and a thickness of 1-1.4mm under a pressure of 100MPa, and the binder is discharged at a heating rate of 150℃ / h at 600℃ for 2 hours, and then heated at 300℃ / h The heating rate is kept at 1550°C for 2 hours, and finally cooled to room temperature with the furnace; the sintered ceramic sheet is ground to 1.00±0.02mm with sandpaper, and silver electrodes are used on both sides. XRD test shows that the ceramic is a single-phase solid solution and no impurity phase is formed. SEM photos show tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com