Method for producing m-cresol with direct hydrolyzation

A hydrolysis method, a technology between production, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry and other directions, can solve the problems of high cost of dilute acid neutralization, consumption of sodium nitrite, serious environmental pollution, etc., to achieve sulfuric acid. The effect of less dosage, less alkali required for neutralization and high product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

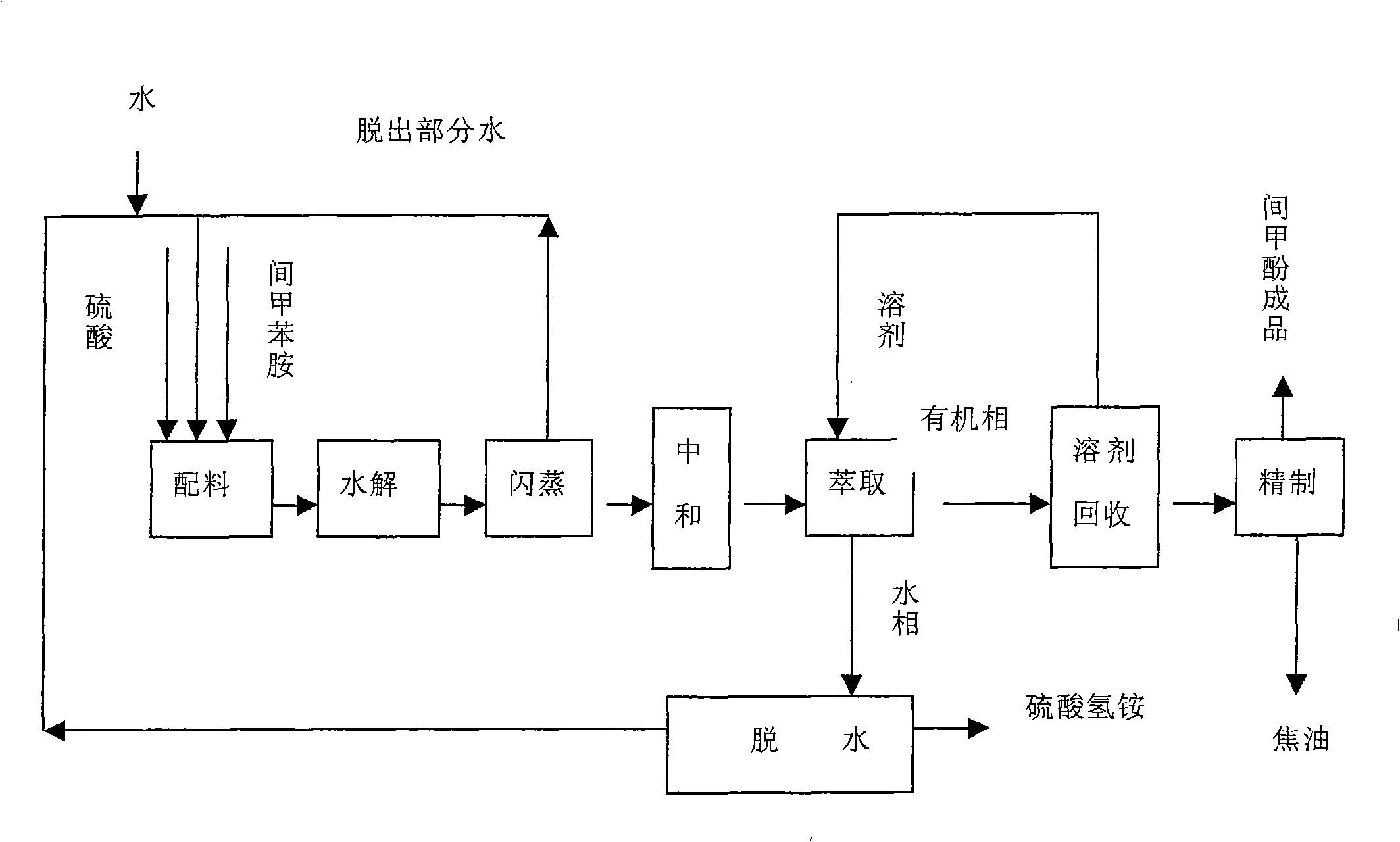

Image

Examples

Embodiment 1

[0018] Embodiment 1: produce m-cresol according to the following steps:

[0019] (1) batching, the sulfuric acid that content is 1% and the m-toluidine aqueous solution that content is 1% are added in the autoclave, mix under agitation;

[0020] (2) hydrolyze, stop stirring and heat up, hydrolyze under the condition of 220 ℃ for 8 hours, generate m-cresol and ammonium bisulfate aqueous solution;

[0021] (3) flash evaporation, the above-mentioned hydrolyzate is carried out normal pressure flash evaporation, reclaims part water and uses for (1) step batching;

[0022] (4) neutralize, add dropwise ammonia solution in the reactor, the pH value is adjusted to 3;

[0023] (5) Extraction, the neutralized kettle liquid is extracted with benzene to remove the m-cresol; the water phase after the extraction is distilled out of which water is used for the (1) step ingredients, and the distillation residue is ammonium bisulfate, which can be used as For fertilizer;

[0024] (6) extract...

Embodiment 2

[0026] Embodiment 2: produce m-cresol according to the following steps:

[0027] (1) batching, the sulfuric acid that content is 5% and the m-toluidine aqueous solution that content is 5% are added in the autoclave, mix under agitation;

[0028] (2) hydrolyze, stop stirring and heat up, hydrolyze under the condition of 200 ℃ for 8 hours, generate m-cresol and ammonium bisulfate aqueous solution;

[0029] (3) flash evaporation, the above-mentioned hydrolyzate is carried out normal pressure flash evaporation, reclaims part water and uses for (1) step batching;

[0030] (4) neutralize, add dropwise ammonia solution in the reactor, adjust the pH value to 4;

[0031] (5) Extraction, the neutralized kettle liquid is extracted with toluene to extract m-cresol therein; the water phase after extraction is distilled out of which water is used for (1) step ingredients, and the distillation residue is ammonium bisulfate, which can be used as For fertilizer;

[0032] (6) extraction agen...

Embodiment 3

[0034] Embodiment 3: produce m-cresol according to the following steps:

[0035] (1) batching, the sulfuric acid that content is 10% and the m-toluidine aqueous solution that content is 10% add in autoclave, mix under agitation;

[0036] (2) hydrolyze, stop stirring and heat up, hydrolyze under the condition of 250 ℃ for 8 hours, generate m-cresol and ammonium bisulfate aqueous solution;

[0037] (3) flash evaporation, the above-mentioned hydrolyzate is carried out normal pressure flash evaporation, reclaims part water and uses for (1) step batching;

[0038] (4) Neutralization, adding aqueous sodium hydroxide solution dropwise to the reactor, adjusting the pH value to 5;

[0039] (5) extraction, extract the m-cresol wherein with butyl acetate extraction of the still liquid after neutralization; Water phase distillation after the extraction goes out wherein water is used for the (1) step batching, and distillation residue is ammonium bisulfate, Can be used as fertilizer;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com