Abandoned white potato haulm/organic montmorillonite composite high-water uptake material and method of producing the same

An organic montmorillonite, potato stem and leaf technology, applied in the polymer field, can solve problems such as waste and environmental pollution, and achieve the effects of shortening the reaction period, reducing pollution and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

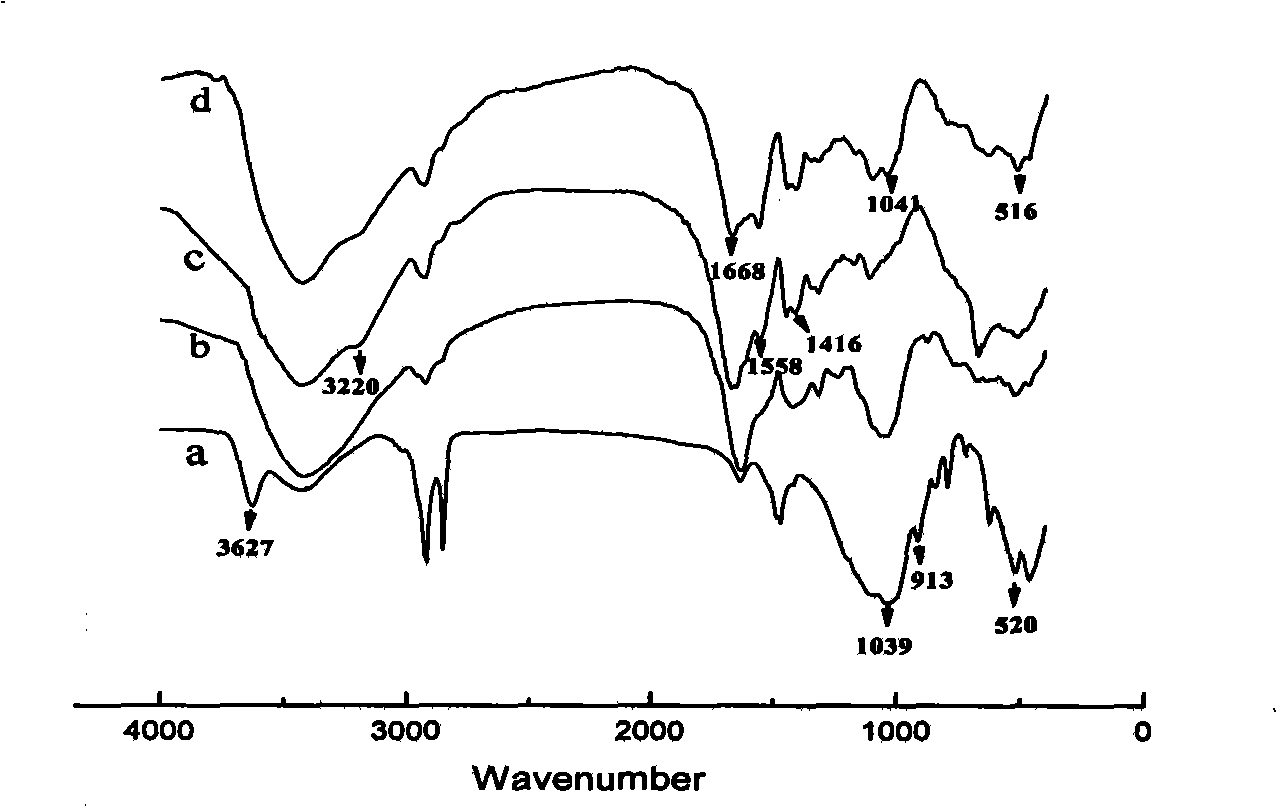

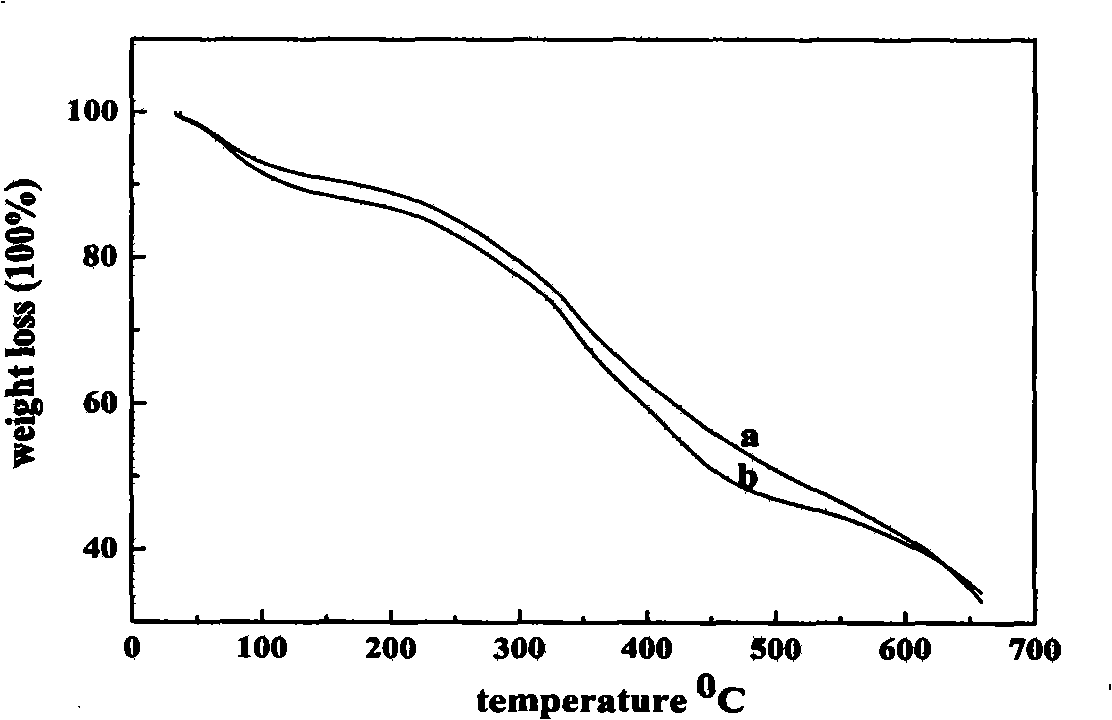

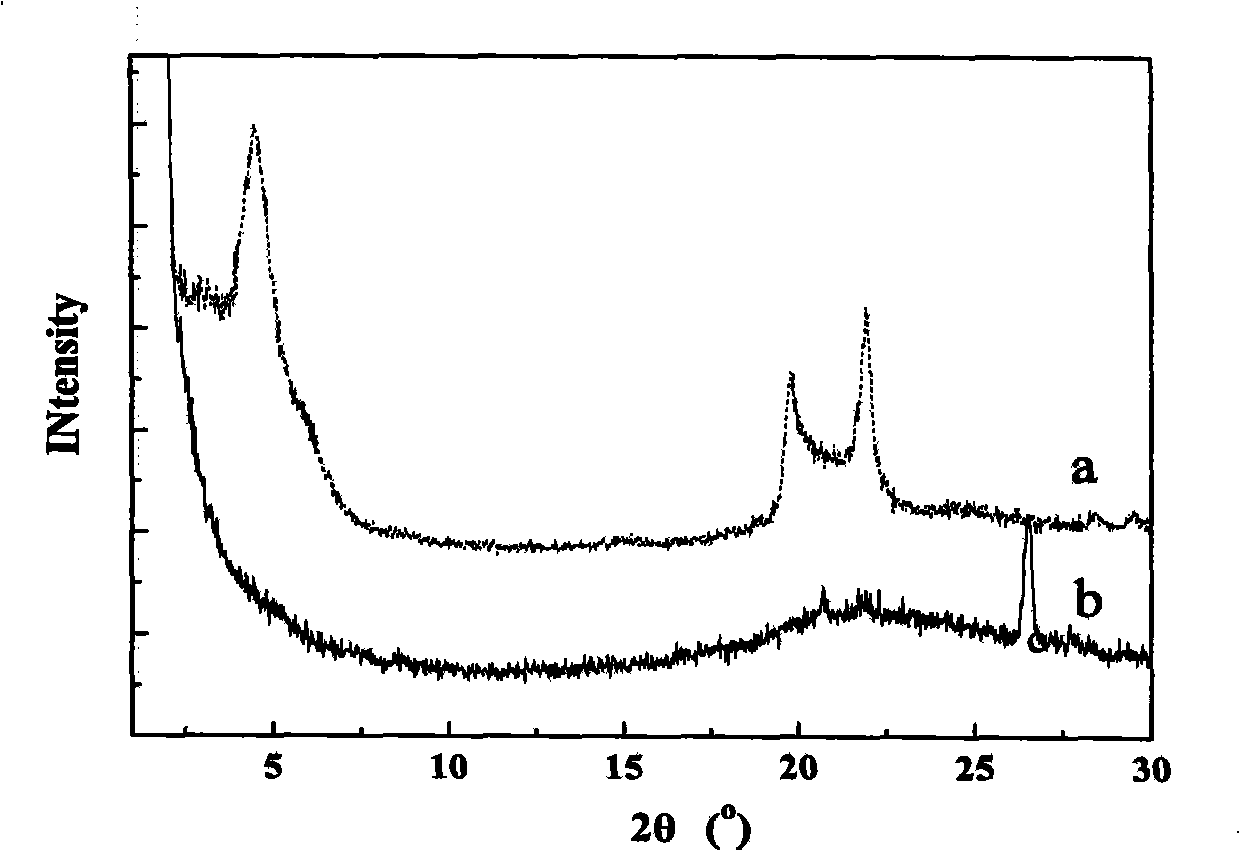

Method used

Image

Examples

Embodiment 1

[0042] Get 0.106kg of organic montmorillonite and disperse it in 11 kg of water, then add 0.264kg of potato stems and leaves (after drying, pulverizing, and filtering with a 200 mesh sieve), mix uniformly, then add potassium persulfate 0.008kg, N, N-methylenebisacrylamide 0.006kg, acrylamide 0.6kg, acrylic acid 0.6kg (acrylic acid is neutralized to 70% by 20% sodium hydroxide in an ice-water bath), fully stirred to obtain a pre-reactant ; Then the obtained pre-reactant was placed in a microwave reaction device, the radiation power was adjusted to 180W, and the radiation time was 5.5min to carry out graft polymerization. After the reaction is completed, the product is soaked in methanol for 4 hours, dried at 40°C, and crushed to obtain the product.

[0043] Measure its water absorption and other properties: its distilled water absorption rate is 470, and the rate of absorbing salt water (0.9%) is 54.

Embodiment 2

[0045] Get 0.096kg of organic montmorillonite and disperse it in 12kg of water, then add 0.286kg of potato stems and leaves (dried, crushed, and filtered through a 200-mesh sieve), mix well, then add 0.008kg of potassium persulfate in turn, N, N- 0.018kg of methylene bisacrylamide, 0.9kg of acrylamide, 0.3kg of acrylic acid (acrylic acid is neutralized by 20% sodium hydroxide in an ice-water bath to a neutralization degree of 75%), fully stirred to obtain a pre-reactant; Then the obtained pre-reactant was placed in a microwave reaction device, the radiation power was adjusted to 180W, and the radiation time was 3.5min to carry out graft polymerization. After the reaction is completed, the product is soaked in methanol for 8 hours, dried at 50°C, and crushed to obtain the product.

[0046] Measure its water absorption and other properties: the ratio of absorbing distilled water is 393, and the ratio of absorbing salt water (0.9%) is 43.

Embodiment 3

[0048] Take 0.06kg of organic montmorillonite and disperse it in 13kg of water, then add 0.3kg of potato stems and leaves (dried, pulverized, and filtered through a 200-mesh sieve), mix well, and then add 0.008kg of potassium persulfate in turn, N, N- Methylenebisacrylamide 0.008kg, acrylamide 0.6kg, acrylic acid 0.6kg (acrylic acid is neutralized to 70% by sodium hydroxide in an ice-water bath), fully stirred to obtain a pre-reactant; then the obtained The pre-reactants were placed in a microwave reaction device, the radiation power was adjusted to 180W, and the radiation time was 4.5min to carry out graft polymerization. After the reaction is completed, the product is soaked in methanol for 10 hours, dried at 30°C, and crushed to obtain the product.

[0049] Measure its water absorption and other properties: the ratio of absorbing distilled water is 773, and the ratio of absorbing salt water (0.9%) is 68.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com