Inorganic filler and organic filler-containing curable resin composition, resist film coated printed wiring board, and method for producing the same

A technology of curing resins and inorganic fillers, applied in printed circuit manufacturing, printed circuits, printed circuits, etc., can solve the problems of limitations, insufficient crack resistance of cured films, inability to impart cured films, etc., to achieve high functionality and excellent resistance. cracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

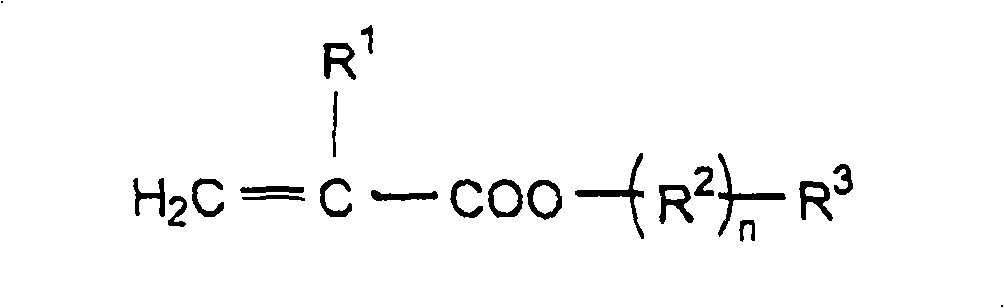

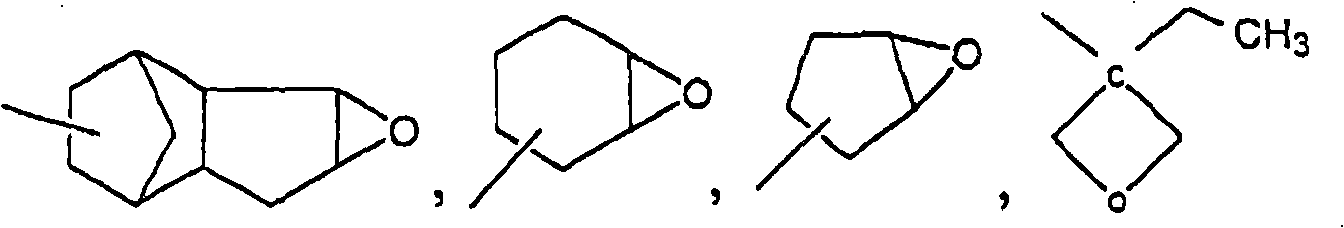

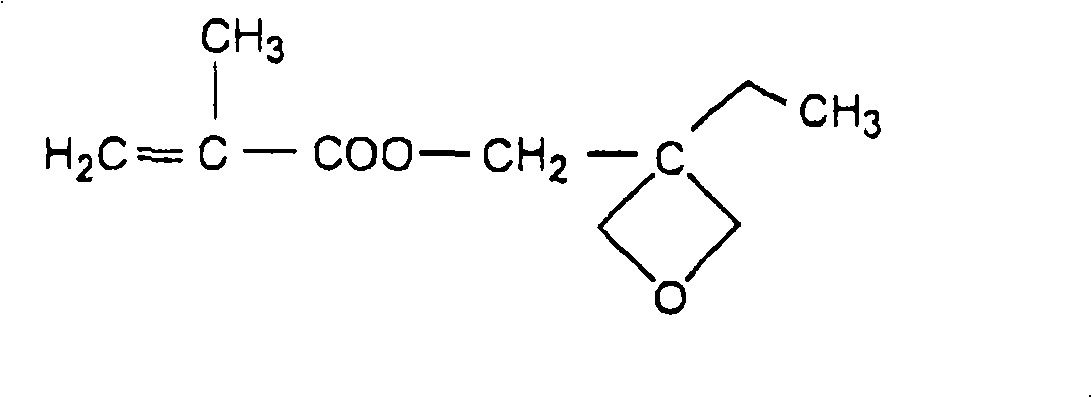

Method used

Image

Examples

preparation Embodiment 1

250 parts by weight of dipropylene glycol monomethyl ether and 10 parts by weight of tert-butyl peroxy-2-ethylhexanoate were added to a separable flask equipped with a stirrer, a thermometer, a reflux condenser, a dropping funnel and a nitrogen introduction pipe, and heat them to 95°C. Then, a mixture of 170 parts by weight of methacrylic acid, 130 parts by weight of methyl methacrylate, 250 parts by weight of dipropylene glycol monomethyl ether and 10 parts by weight of azobisdimethylvaleronitrile was added dropwise thereto over a period of 4 hours. . In addition, these were aged for 5 hours to obtain a carboxyl group-containing methacrylic acid-methyl methacrylate copolymer solution. Next, let a mixed gas of 7% oxygen-93% nitrogen pass through this resin solution at the same time, add 200 parts by weight of (3,4-epoxycyclohexyl) methyl methacrylate, 2 parts by weight of triphenylphosphine and 1 part by weight of hydroquinone monomethyl ether, and their addition reaction was ...

preparation Embodiment 2

To a separable flask equipped with a reflux condenser, a thermometer, a glass tube for nitrogen replacement, and a stirrer, add 140 parts by weight of glycidyl methacrylate, 60 parts by weight of methyl methacrylate, 200 parts by weight of carbitol Acetate, 0.4 parts by weight of lauryl mercaptan, and 6 parts by weight of azobis(isobutyronitrile). They were heated in a nitrogen stream, and polymerized at 75° C. for 5 hours to obtain a 50% copolymer solution. To the above 50% copolymer solution, 0.1 parts by weight of hydroquinone, 74 parts by weight of acrylic acid, and 0.4 parts by weight of dimethylbenzylamine were added, and their addition reaction was performed at 100° C. for 24 hours. Then, 90 parts by weight of tetrahydrophthalic anhydride and 158 parts by weight of carbitol acetate were added thereto, and they were reacted at 100° C. for 3 hours to obtain a compound having a solid content of 50% and a double bond equivalent of 350 g / mol. , an acid value of 91 mgKOH / g an...

preparation Embodiment 3

215 parts by weight of a cresol novolac type epoxy resin (N-680 produced by Dainippon Ink & Chemicals, Inc., epoxy equivalent = 215) was put into a four-necked flask equipped with a stirrer and a reflux condenser. 196 parts by weight of propylene glycol monomethyl ether acetate was added thereto, and dissolved under heating. Next, 0.46 parts by weight of methylhydroquinone as a polymerization inhibitor and 1.38 parts by weight of triphenylphosphine as a reaction catalyst were added thereto. This mixture was heated at 95-105°C, and 72 parts by weight (1 equivalent) of acrylic acid was gradually added dropwise thereto. These were reacted for about 32 hours to obtain a reaction product having an acid value of 0.9 mgKOH / g. This reaction product (hydroxyl group: 1 equivalent) was cooled to 80-90°C, and 76 parts by weight (0.5 equivalent) of tetrahydrophthalic anhydride was added thereto. They were allowed to react for about 8 hours and discharged after cooling. Thus, a carboxyl g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com